Pretreatment method for photocatalyst for cyclohexane decomposing in oil field station

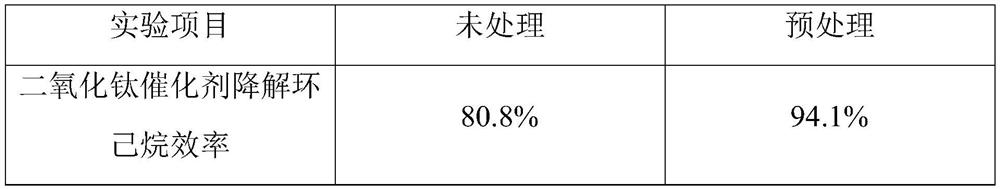

A photocatalyst, cyclohexane technology, applied in separation methods, chemical instruments and methods, catalyst activation/preparation, etc., can solve the lack of direct and effective treatment of decomposition of cyclohexane, the inability to achieve real-time monitoring, There are no problems such as treatment of cyclohexane gas, so as to improve the photocatalyst activity and the degradation rate of cyclohexane, improve the photon efficiency, and improve the adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

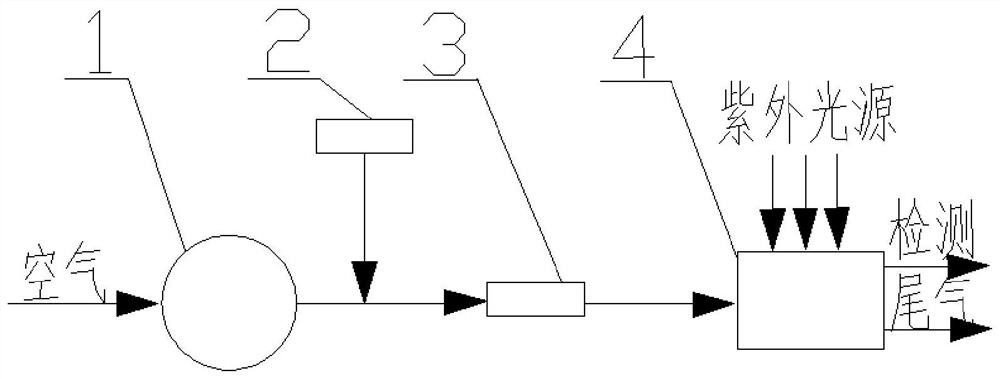

Image

Examples

Embodiment 1

[0031] Titanium dioxide catalyst product preparation:

[0032] 10 g of titanium dioxide in a mixed phase of anatase crystal and rutile crystal with an average particle size of basic particles of about 21 nm is selected, and the weight ratio of anatase and rutile is about 71 / 29. Put the selected mixed-phase titanium dioxide into a muffle furnace, bake it at 415°C for 1.5h, put it into a desiccator to cool naturally, and set it aside.

[0033] Magnetically stir 10 g of the mixed-phase titanium dioxide treated in the first step in 10 ml of 1 mol / L sulfuric acid for 1 h, and set aside.

[0034] 10g of the mixed titanium dioxide treated in the second step was irradiated in a 650w, 2400Hz microwave oven for 4 minutes, cooled, and set aside.

[0035] Magnetically stir 10g of mixed titanium dioxide treated in the third step in 10ml of 0.5mol / L sulfuric acid for 1h, take it out, put it in a muffle furnace, bake it at 300°C for 1h, put it in a desiccator and cool it down naturally.

Embodiment 2

[0037] Titanium dioxide catalyst product preparation:

[0038] (1) Select 100 g of titanium dioxide in a mixed phase of anatase crystal and rutile crystal with an average particle diameter of about 18 nm as the basic particle, and the weight ratio of anatase and rutile is about 71 / 29. Put the selected mixed-phase titanium dioxide into a muffle furnace, bake it at 410°C for 1 hour, put it into a desiccator to cool naturally, and set it aside.

[0039] (2) Magnetically stir 100 g of the mixed-phase titanium dioxide treated in the first step in 100 ml of 1 mol / L sulfuric acid for 1 h, and set aside.

[0040] (3) 100 g of the mixed titanium dioxide treated in the second step was irradiated with 640w and 2300 Hz microwave for 3 minutes, cooled and set aside.

[0041] (4) Magnetically stir 100g of the mixed titanium dioxide treated in the third step in 100ml of 0.5mol / L sulfuric acid for 1h, take it out, put it in a muffle furnace, bake it at 300°C for 0.5h, and put it in a desicca...

Embodiment 3

[0043] Titanium dioxide catalyst product preparation:

[0044] (1) Select 100 g of titanium dioxide in a mixed phase of anatase crystal and rutile crystal with an average particle diameter of about 25 nm as the basic particle, and the weight ratio of anatase and rutile is about 71 / 29. Put the selected mixed-phase titanium dioxide into a muffle furnace, bake it at 420°C for 2h, put it into a desiccator to cool naturally, and set it aside.

[0045] (2) Magnetically stir 100 g of the mixed-phase titanium dioxide treated in the first step in 100 ml of 1 mol / L sulfuric acid for 1 h, and set aside.

[0046] (3) 100 g of the mixed titanium dioxide treated in the second step was irradiated with 660w and 2500 Hz microwave for 5 minutes, cooled and set aside.

[0047] (4) Magnetically stir 100 g of the mixed titanium dioxide treated in the third step in 100 ml of 0.5 mol / L sulfuric acid for 1 h, take it out, put it in a muffle furnace, bake it at 310 ° C for 2 h, and put it in a desicc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com