Methacrylic resin and preparation method and application thereof

A technology of methacrylic acid and resin, which is applied in the field of photoresist, can solve the problems of high molecular weight cost, difficult control, and unsatisfactory effect, and achieve the effect of increasing the degree of confusion and reducing molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

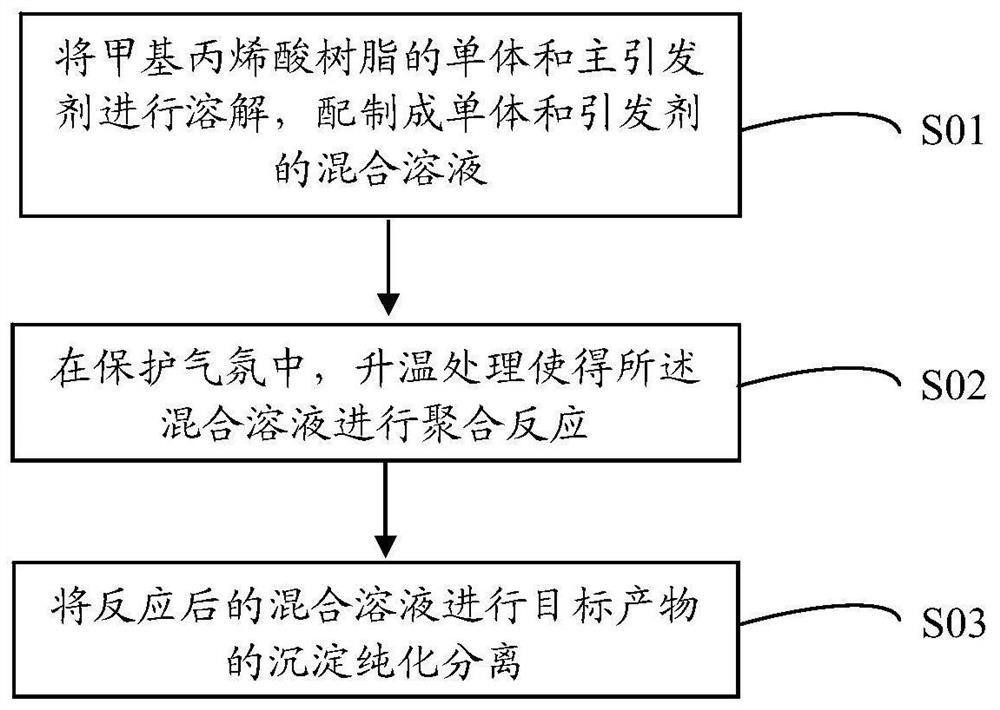

[0016] The embodiment of the present invention provides a method for preparing methacrylic resin. Described methacrylic resin preparation method comprises the steps:

[0017] Step S01: dissolving the monomer and the main initiator of the methacrylic resin to prepare a mixed solution of the monomer and the initiator;

[0018] Step S02: In a protective atmosphere, heat up treatment so that the mixed solution undergoes a polymerization reaction.

[0019] Wherein, in the step S01, the monomer of the methacrylic resin and the main initiator are dissolved to construct a reactant mixed solution system to effectively generate the target product under the action of the main initiator, and the described The ratio and concentration of the main initiator and the monomer are used to optimize the reaction system. In one embodiment, control the monomer and the main initiator according to the content of the main initiator to carry out mixed solvent in the ratio of 1%-10% of the total mass o...

Embodiment 1

[0037] The present embodiment one provides a kind of preparation method of methacrylic resin, comprises the following steps:

[0038] (1) 5 parts of methyl methacrylate, 3 parts of butyl acrylate and 2 parts of 2-methyl-2-adamantyl methacrylate are placed in a four-necked flask with ethyl acetate, Stir until the monomers are dissolved, wherein the amount of ethyl acetate used to dissolve the monomers is 3 times the total mass of the monomers;

[0039] (2) After the monomer is dissolved, add tert-butyl peroxybenzoate, stir until dissolved, and the usage amount of tert-butyl peroxybenzoate is 1.3% of the total mass of the monomer;

[0040] (3) Place the four-neck flask with the reaction solution in an oil bath equipped with a magnetic stirrer, install the condenser tube, and the nitrogen port, turn on the condensed water, feed nitrogen, turn on the stirring and raise the temperature to 77°C for free radical polymerization;

[0041] (4) backflow reaction to 5h;

[0042] (5) In...

Embodiment 2

[0047] The present embodiment provides a kind of preparation method of methacrylic resin, comprises the following steps:

[0048] (1) 5 parts of methyl methacrylate, 3 parts of butyl acrylate and 2 parts of 2-methyl-2-adamantyl methacrylate are placed in a four-necked flask with ethyl acetate, Stir until the monomers are dissolved, wherein the amount of ethyl acetate used to dissolve the monomers is 3 times the total mass of the monomers;

[0049] (2) After the monomer is dissolved, add tert-butyl peroxybenzoate, stir until dissolved, and the usage amount of tert-butyl peroxybenzoate is 1.3% of the total mass of the monomer;

[0050] (3) Place the four-neck flask with the reaction solution in an oil bath equipped with a magnetic stirrer, install the condenser tube, and the nitrogen port, turn on the condensed water, feed nitrogen, turn on the stirring and raise the temperature to 77°C for free radical polymerization;

[0051] (4) backflow reaction to 5h;

[0052] (5) The in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com