Temperature-sensitive polymer, foam fracturing fluid as well as preparation method and application thereof

A foam fracturing fluid and polymer technology, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of increased fluid loss, poor foam quality, and rheological effects of fracturing fluid, and achieve increased viscosity , good foam stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

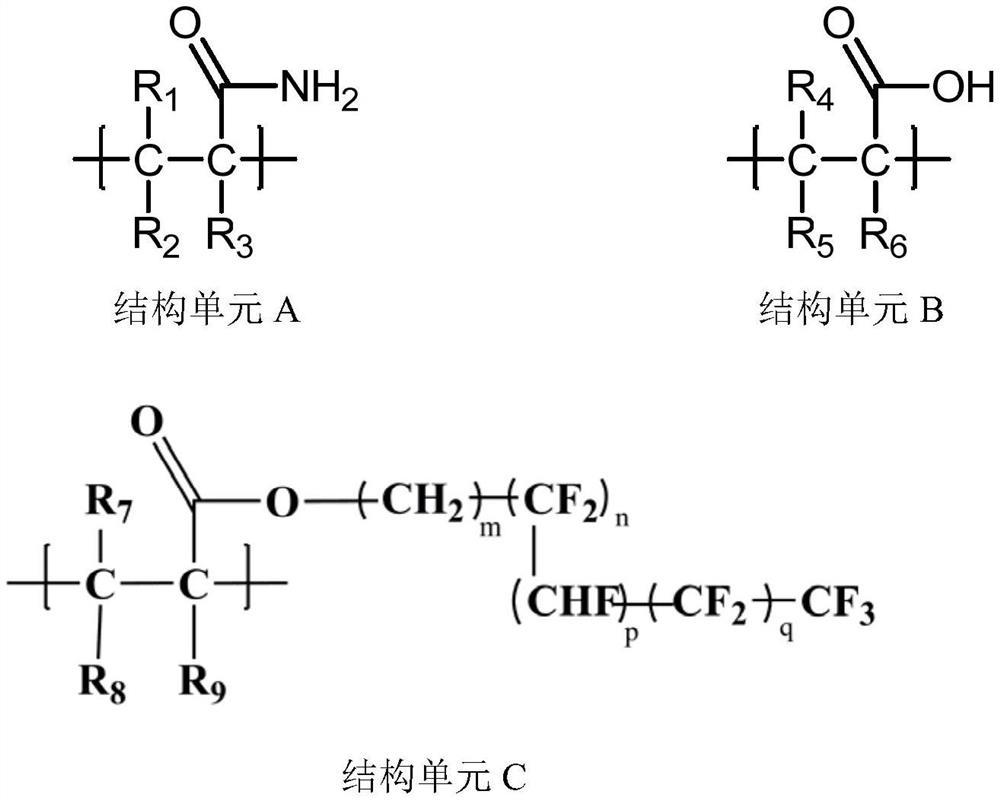

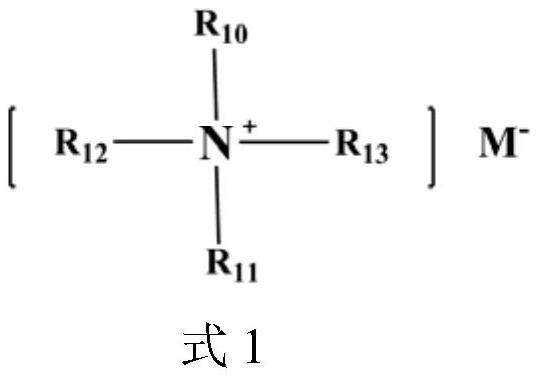

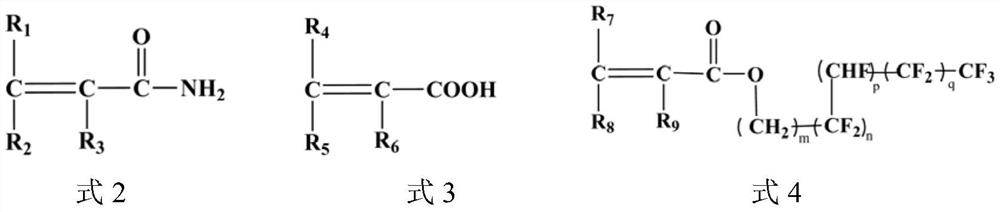

Method used

Image

Examples

Embodiment 1

[0074] This example is to prepare a foam fracturing fluid system, which is composed of: 0.4% of thermosensitive polymer, 0.3% of clay stabilizer, 0.2% of foaming agent, 0.4% of crosslinking agent, 98.7% of water, CO 2 gas.

[0075] The clay stabilizer is KCl and choline chloride, the mass ratio of the two is 1:1; the foaming agent is perfluorolauryl polyoxyethylene ether and betaine, the mass ratio of the two is 1:5; the crosslinking agent is titanium Butyl acid, lactic acid and ethylene glycol, the mass ratio of the three is 1:6:3.

[0076] Preparation of thermosensitive polymers:

[0077] Four monomers of acrylamide, acrylic acid, hexafluorobutyl methacrylate, and hexadecyldimethylallyl ammonium chloride were sequentially added in deionized water until dissolved; The monomer accounts for 30% of the reaction solution, 50 parts of acrylamide, 45 parts of acrylic acid, 3 parts of hexafluorobutyl methacrylate, and 2 parts of hexadecyldimethylallyl ammonium chloride; in the abo...

Embodiment 2

[0085] This example is to prepare a foam fracturing fluid system, which consists of: 0.5% thermosensitive polymer, 0.3% clay stabilizer, 0.2% foaming agent, 0.5% crosslinking agent, 98.5% water, CO 2 gas.

[0086] The clay stabilizer is KCl and choline chloride, the mass ratio of the two is 1:1; the foaming agent is perfluorolauryl polyoxyethylene ether and betaine, the mass ratio of the two is 1:5; the crosslinking agent is titanium Butyl acid, lactic acid and ethylene glycol, the mass ratio of the three is 1:6:3.

[0087] Preparation of thermosensitive polymers:

[0088] Four monomers of acrylamide, acrylic acid, hexafluorobutyl methacrylate, and hexadecyldimethylallyl ammonium chloride were sequentially added in deionized water until dissolved; The monomer accounts for 30% of the reaction solution, 50 parts of acrylamide, 45 parts of acrylic acid, 3 parts of hexafluorobutyl methacrylate, and 2 parts of hexadecyldimethylallyl ammonium chloride; in the above solution Add 3...

Embodiment 3

[0096] This example is to prepare a foam fracturing fluid system, which consists of: 0.6% thermosensitive polymer, 0.3% clay stabilizer, 0.2% foaming agent, 0.6% crosslinking agent, 98.3% water, CO 2 gas.

[0097] The clay stabilizer is KCl and choline chloride, the mass ratio of the two is 1:1; the foaming agent is perfluorolauryl polyoxyethylene ether and betaine, the mass ratio of the two is 1:5; the crosslinking agent is titanium Butyl acid, lactic acid and ethylene glycol, the mass ratio of the three is 1:6:3.

[0098] Preparation of thermosensitive polymers:

[0099] Four monomers of acrylamide, acrylic acid, hexafluorobutyl methacrylate, and hexadecyldimethylallyl ammonium chloride were sequentially added in deionized water until dissolved; The monomer accounts for 30% of the reaction solution, 50 parts of acrylamide, 45 parts of acrylic acid, 3 parts of hexafluorobutyl methacrylate, and 2 parts of hexadecyldimethylallyl ammonium chloride; in the above solution Add 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com