Etching composition and etching method using same

A composition and etching technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of reduced adhesion between copper film and molybdenum film, overetching of etching composition, molybdenum alloy residue, etc., and achieve excellent etching Performance, low cone angle, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] Hydrogen peroxide 20% by weight, iminodiacetic acid (Iminodiacetic acid, IDA) 3% by weight, adenine 0.1% by weight, ammonium fluoride (Ammonium fluoride, AF) 0.1% by weight, and the ingredients described in the following Table 1 It was mixed with the rest of water to prepare an etching composition.

Embodiment 2 to 7

[0116] In Example 1, except having changed the component and content described in following Table 1, it implemented by the method similar to Example 1, and manufactured the etching composition.

experiment example 1

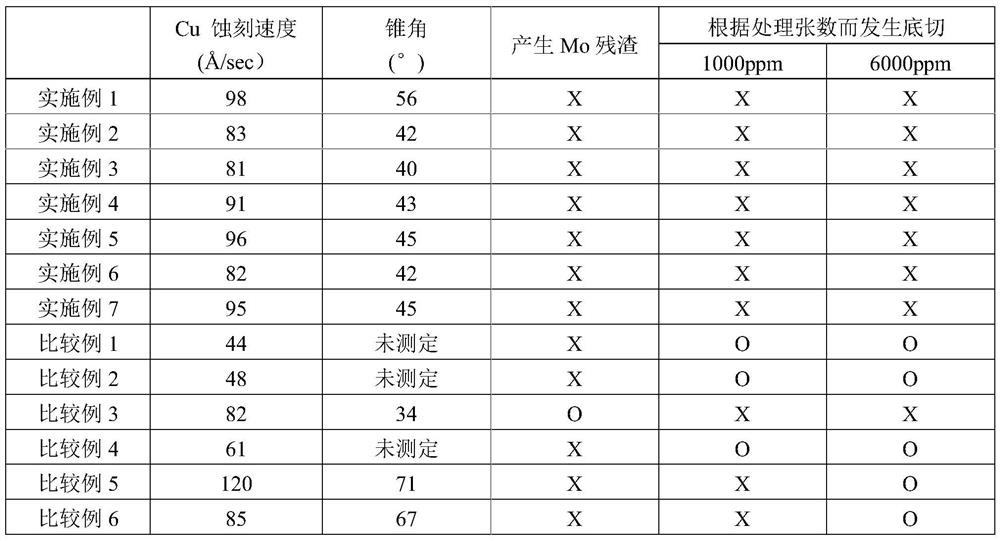

[0132] [Experimental Example 1] Etching characteristic evaluation

[0133] Evaporate the thickness in turn on the glass substrate The copper film and molybdenum film were used to manufacture test pieces. A photoresist process was performed on the test piece to form a patterned resist film, and the copper and molybdenum films were etched using the etching compositions of Examples 1 to 7 and Comparative Examples 1 to 5, respectively. At this time, in the above-mentioned etching step, etching was performed by adding 50% overetching to EPD (end point detection) measured at 32° C. with a sprayable equipment (Mini-etcher ME-001). Regarding the EPD measurement, it was measured by visually observing the color change of the test piece during etching, and using a scanning electron microscope (Hitachi, S-4800) to observe whether the taper angle, molybdenum residue, and undercut according to the number of sheets processed occurred.

[0134] The results are described in Table 2 below. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com