Lead particle and lead paste smelting reduction device

A technology of lead paste and lead granules, which is applied in the direction of preheating costs, waste heat treatment, waste collector recycling, etc., can solve the problems of ineffective use of waste heat of flue gas and low thermal efficiency of lead reduction devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

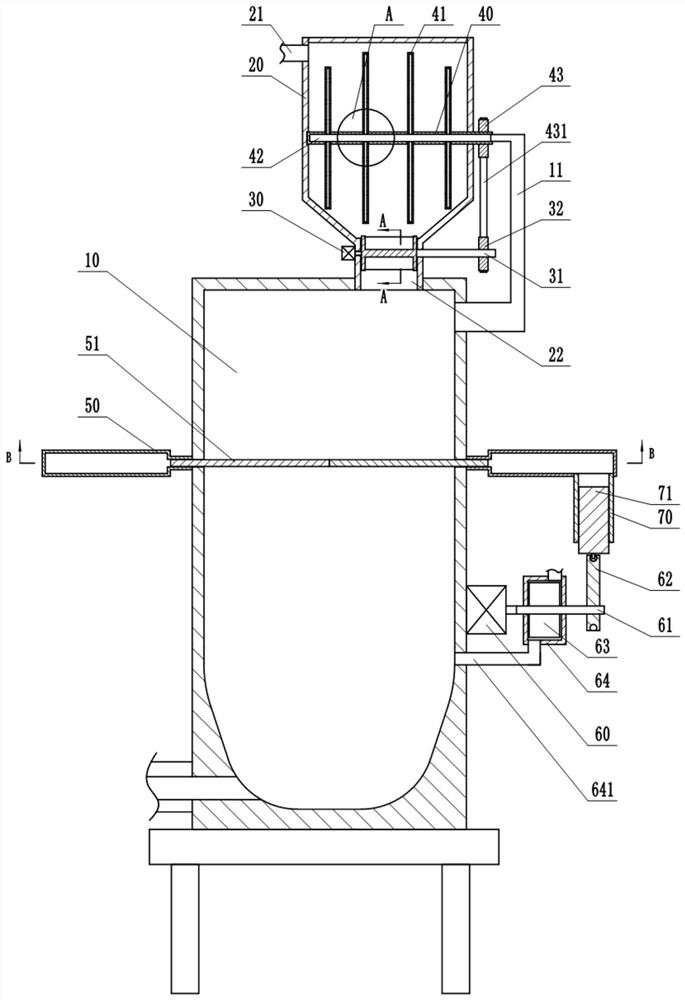

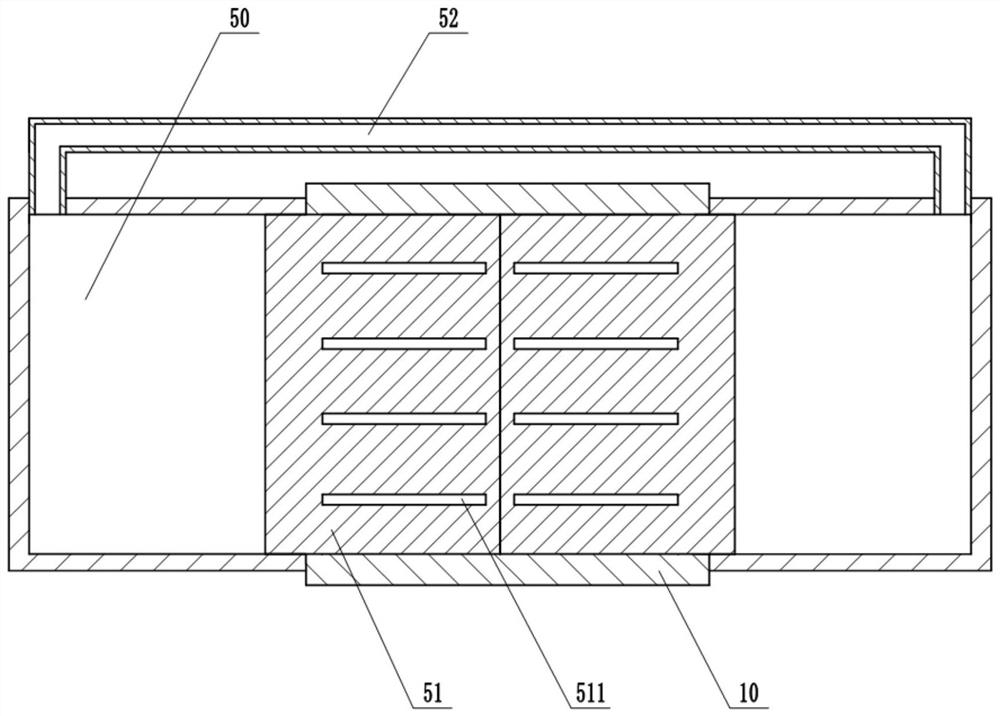

[0033] This embodiment is basically asfigure 1 Shown: lead pellets, lead paste smelting reduction device, including furnace body 10, storage bin 20 and discharge mechanism, storage bin 20 is fixedly installed above the furnace body 10, and the upper part of storage bin 20 is connected with an outlet pipe 21 A discharge channel 22 is connected to the lower part of the storage bin 20 , and the discharge channel 22 communicates with the upper part of the furnace body 10 .

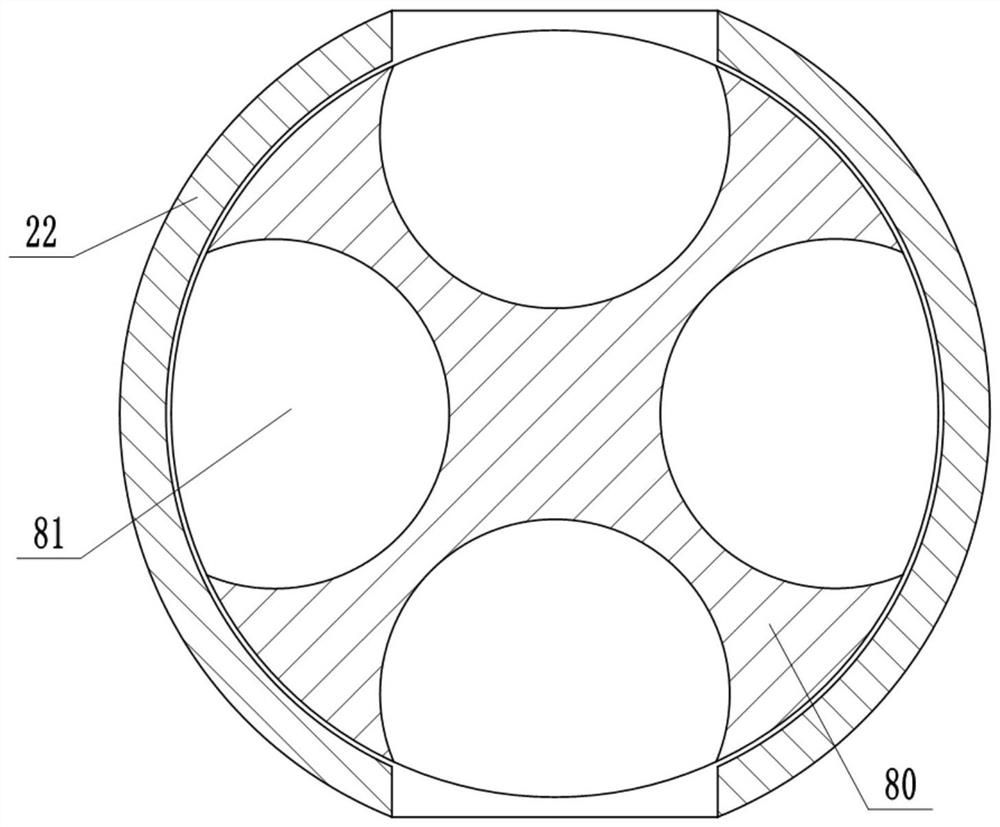

[0034] The discharge mechanism includes a motor 30 fixedly installed on the side wall of the discharge passage 22 and a discharge member rotatably connected in the discharge passage 22. Specifically, the output shaft of the motor 30 is welded on the side wall of the discharge member. A connecting shaft 31 is welded at the center of rotation of the material, and the connecting shaft 31 passes through the side wall of the discharge channel 22 and is located outside the discharge channel 22 . combine figure 2 A...

Embodiment 2

[0041] The difference between the present embodiment and the first embodiment is that the discharge member of the present embodiment is different from the first embodiment, and there is no connecting rod on the plunger 71 of this embodiment, and there is no groove on the cam 62 . combine Figure 5 , Figure 6 As shown, in this embodiment, the discharge member includes a central shaft 90 located in the discharge channel 22 and a plurality of partitions 91 fixed on the central shaft 90, and the plurality of partitions 91 are uniform along the circumference of the central shaft 90. Distributed, a receiving groove is formed between adjacent partitions 91, and the receiving groove can be used for transporting materials. The two opposite side walls of the discharge channel 22 are arc-shaped, and the end of the partition 91 can be in contact with the inner wall of the discharge channel 22 . The connecting cylinder 70 is provided with an elastic member 642 . In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com