Asymmetric composite film based on ordered mesoporous carbon, super-assembly preparation method and application thereof

A mesoporous carbon and composite membrane technology, applied in the field of porous materials, can solve problems such as difficult to prepare pore structures, and achieve the effect of easy-to-obtain raw materials and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

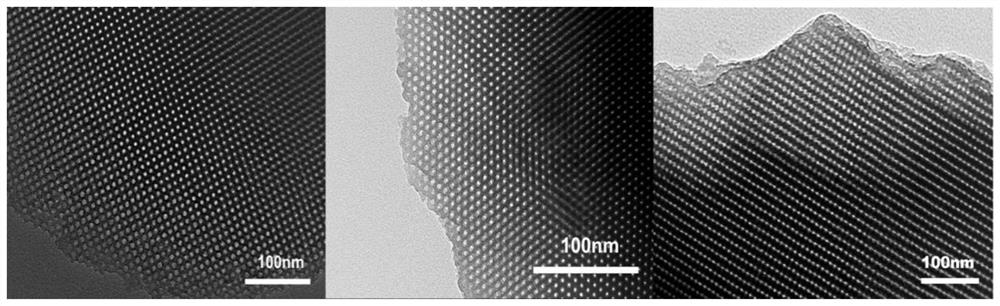

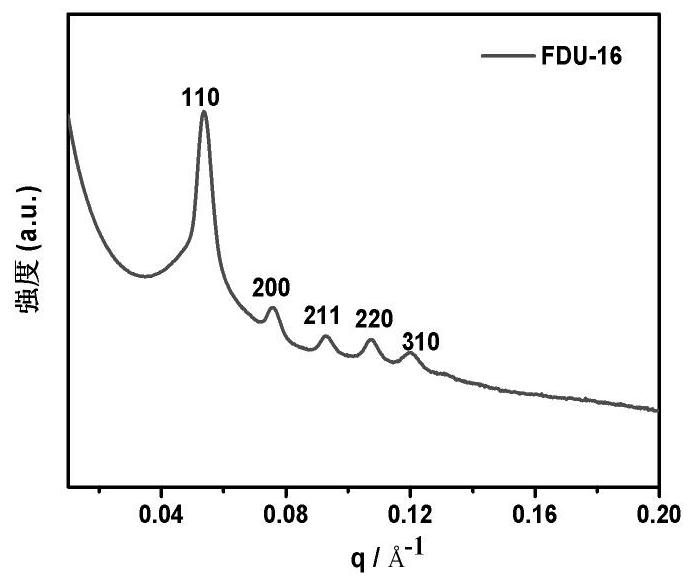

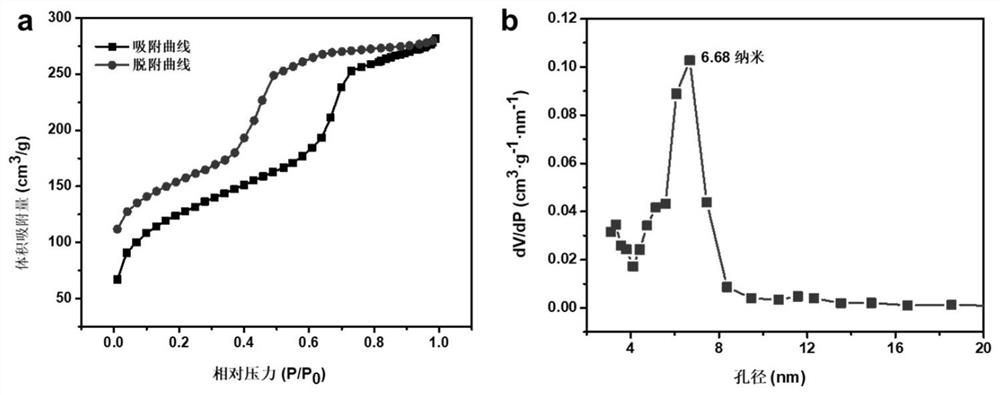

[0037] This example describes in detail the asymmetric composite membrane based on ordered mesoporous carbon, its preparation method and application.

[0038] In this example, an asymmetric composite membrane based on ordered mesoporous carbon was prepared by superassembly method.

[0039] Step 1, dissolve 1.0g of F127 in 20.0g of ethanol, sonicate it until clarified to obtain a template solution; then add 5.0g of resol ethanol solution containing 0.61g of phenol and 0.39g of formaldehyde, and stir for 10 minutes to obtain Uniform clear and transparent mesoporous carbon precursor solution.

[0040] In step 2, at a speed of 3300 r / min, the above-mentioned mesoporous carbon precursor solution is coated on the AAO substrate with plugged pores by spin coating to obtain a composite membrane.

[0041] Step 3: Evaporate the above composite film in an oven at 40°C to induce self-assembly for 12 hours, and then raise the temperature of the oven to 100°C for thermal polymerization;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com