Environment-friendly anhydrous stemming for multi-taphole blast furnace, and preparation method thereof

An anhydrous taphole clay and environmental protection technology, applied in the field of blast furnace refractories, can solve problems such as unreasonable formula matching, threat to workers' health, poor working conditions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

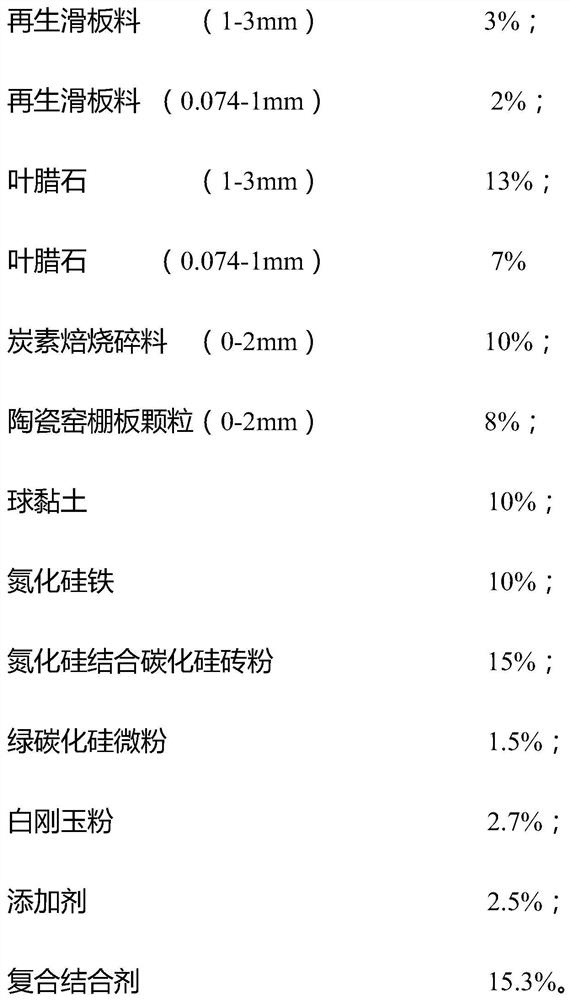

[0038] A kind of environment-friendly anhydrous taphole clay for multi-tap furnace, which is composed of aggregate, powder and composite binder, wherein the mass ratio of aggregate, powder and composite binder is 43:41.7:15.3, according to the mass percentage In total, each raw material is composed of:

[0039]

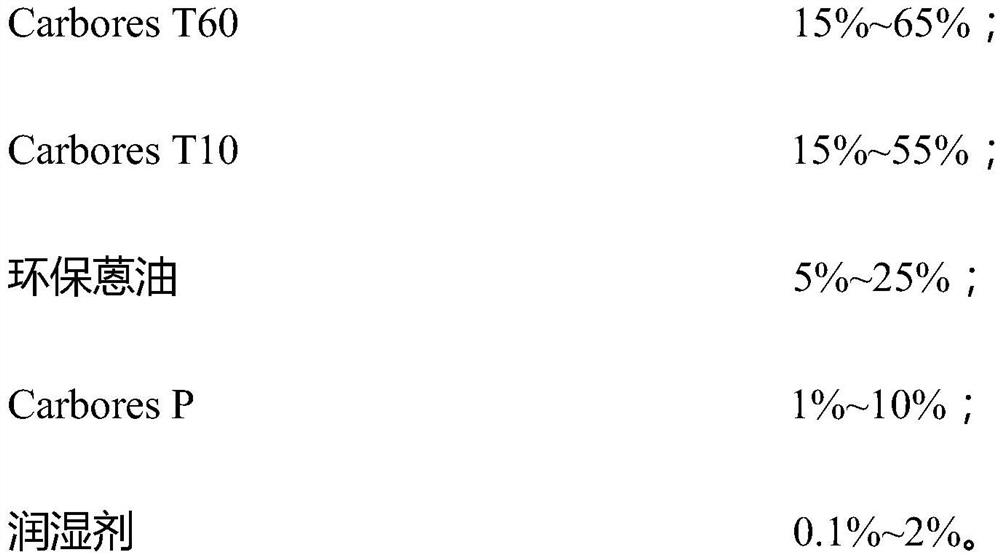

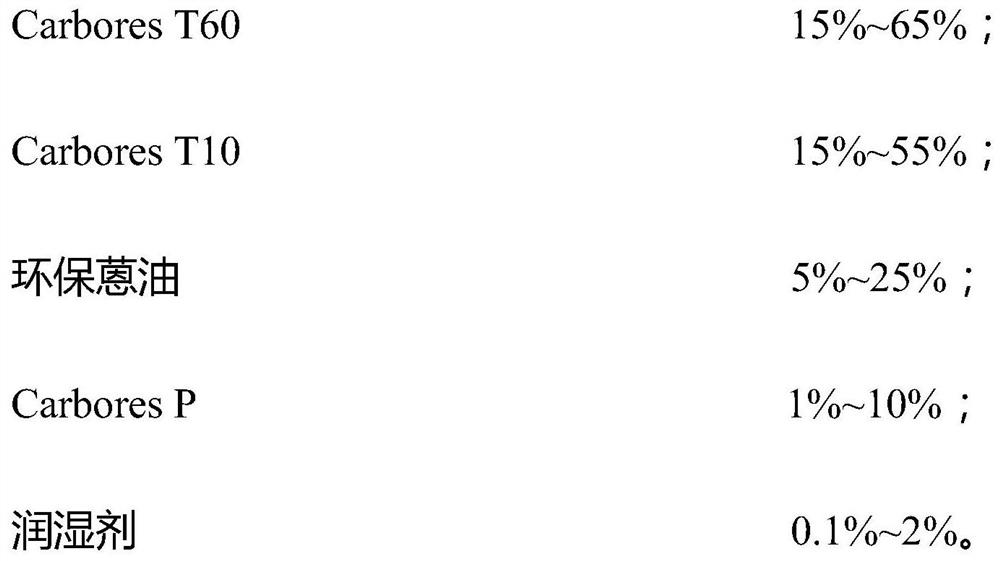

[0040] Wherein, the composite binder, in terms of mass percentage, each raw material is composed of:

[0041]

[0042]

[0043] A kind of preparation method of environment-friendly anhydrous taphole mud for multi-tap furnace, comprises the following steps:

[0044] (1) Weigh each raw material according to the formula, first put Carbores T60, Carbores T10, environmental protection anthracene oil, CarboresP and wetting agent into a reaction kettle at 120°C and mix and stir for 8 hours to prepare a composite binder for future use; clay, Ferrosilicon nitride, silicon nitride combined with silicon carbide brick powder, green silicon carbide micropowder, white cor...

Embodiment 2

[0050] This example is basically the same as Example 1, except that it is an environmentally friendly anhydrous taphole clay for a multi-tap blast furnace, which is composed of aggregate, powder and composite binder, wherein the aggregate, powder and composite binder The mass ratio is 45: 40.2: 14.8, and according to mass percentage, each raw material is composed of:

[0051]

[0052]

[0053] Wherein, the composite binder, in terms of mass percentage, each raw material is composed of:

[0054]

[0055] The pot clay product that present embodiment 2 makes is 2280m in a certain domestic foundry enterprise volume 3 , used on a blast furnace with 3 tapholes, the wind pressure is 420-430KPa, the top pressure is 210-220KPa, the daily output of molten iron is 5800-6000 tons, and the average interval of tapping is 30min. After the gun mud is used, the depth of the taphole is maintained at 3.0- 3.2 meters, the amount of mud per furnace is about 250kg, and the number of iron ...

Embodiment 3

[0057] This example is basically the same as Example 1, except that it is an environmentally friendly anhydrous taphole clay for a multi-tap blast furnace, which is composed of aggregate, powder and composite binder, wherein the aggregate, powder and composite binder The mass ratio is 45: 41.42: 13.6, and according to mass percentage, each raw material is composed of:

[0058]

[0059] Wherein, the composite binder, in terms of mass percentage, each raw material is composed of:

[0060]

[0061]

[0062] The pot clay product that present embodiment 3 makes is 2680m in a certain domestic foundry enterprise volume 3 , used on a blast furnace with 3 tapholes, the wind pressure is 380-390KPa, the top pressure is 215-225KPa, and the daily output of molten iron is 6,700 tons. About 230kg or so, the number of ironing times per day is reduced from 12 to 11 furnaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com