High-adhesion graphene conductive glove and preparation process thereof

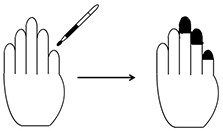

A technology with high adhesion and preparation technology, applied in gloves, conductive coatings, clothing, etc., can solve problems such as finger and screen capacitance failure, failure to send commands, etc., to improve service life, improve coating adhesion, and save raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with specific examples.

[0013] Graphene with a purity of 90% is used as a conductive substance, and water-based polyurethane is used as a binder to equip a water-based paint. Prepare 10 ml of graphene solution with a mass fraction of 0.1% in a 30 ml vial, add 100 mg of sodium dodecylbenzene sulfonate, and ultrasonicate for 60 min to prepare a graphene dispersion. Pour the graphene dispersion into a small beaker, add triton and water-based polyurethane under low-speed mechanical stirring to make the concentration reach 3wt% and 0.5wt%, and obtain the graphene coating. Use a dropper to coat the graphene coating on the glove substrate at a temperature of 130°C, dry it, and carefully immerse it in deionized water for 10 minutes, then take it out and dry it, wash it twice with a large amount of deionized water, and dry it to prepare graphite vinyl conductive gloves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com