Equipment and process for removing burrs from group holes

A technology of burrs and group holes, which is applied in the field of mechanical processing and manufacturing, can solve the problems of difficult to ensure the consistency of burr removal, low efficiency of group hole burr removal, and difficult to guarantee the quality of grinding, so as to achieve good consistency of grinding quality and smooth grinding stroke. The effect of increasing and improving the grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

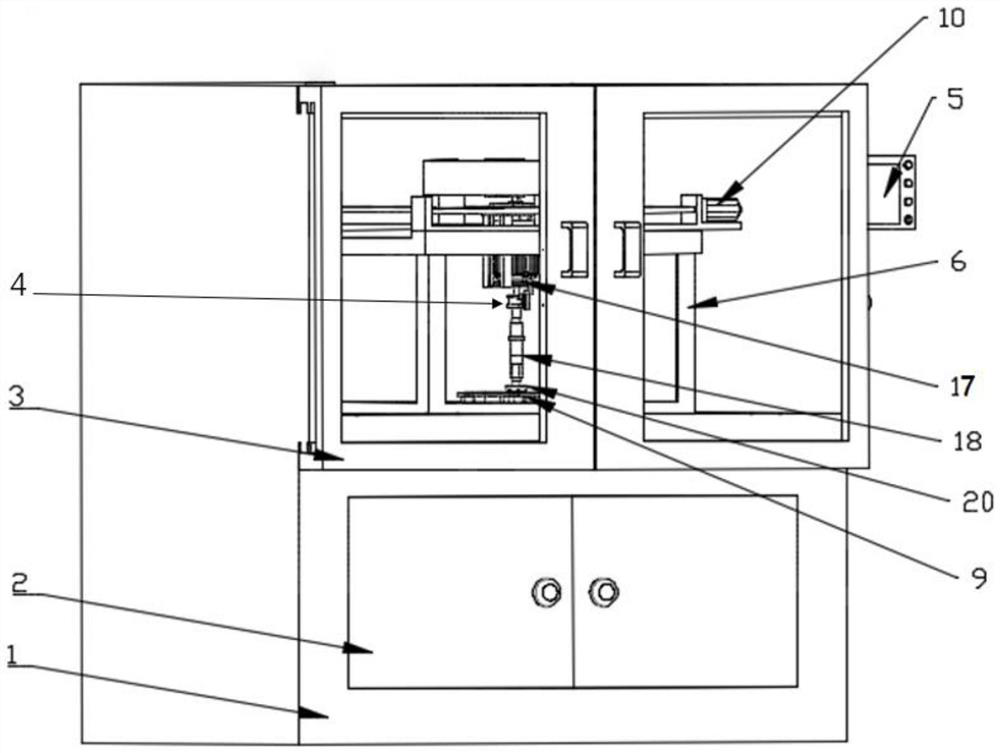

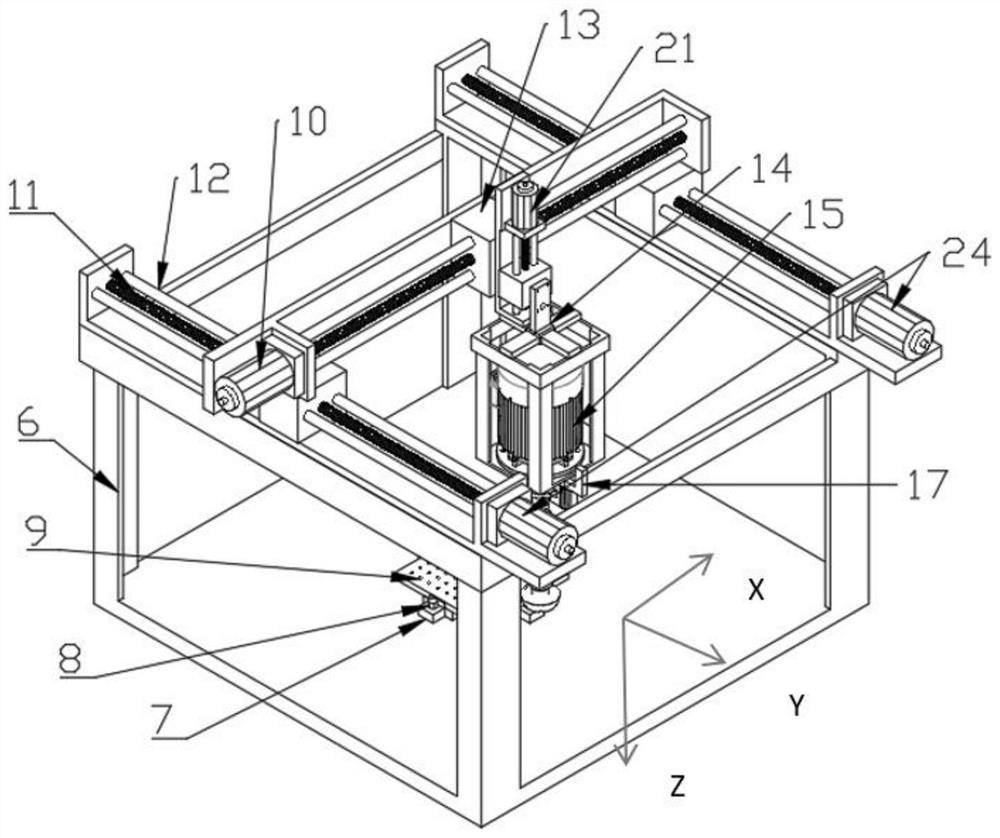

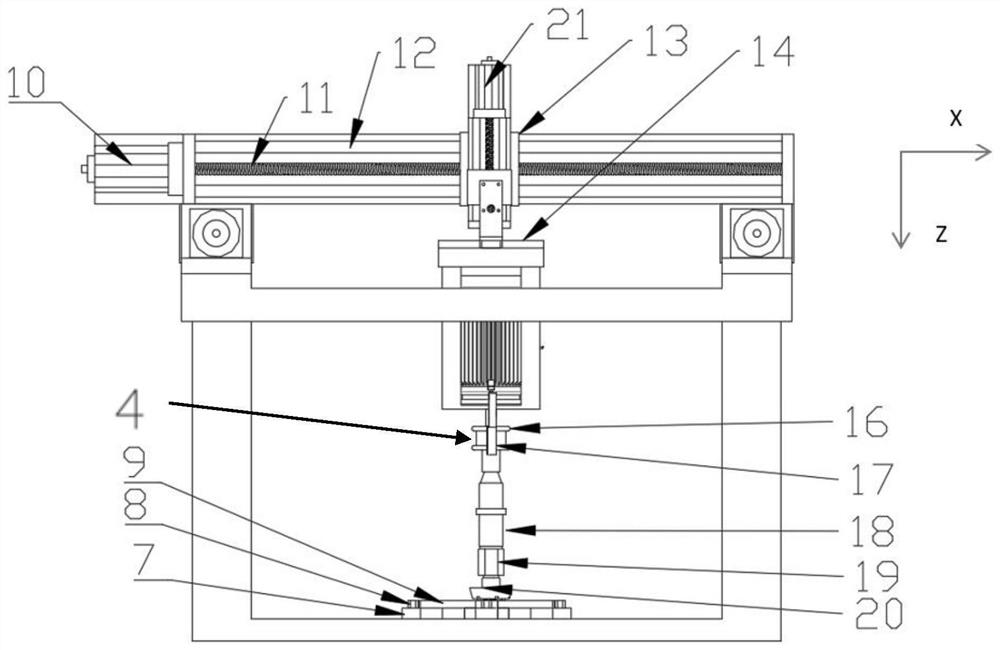

[0040] The invention can grind the SUS304 plate-type group-hole workpiece with the group hole diameter of 3mm-6mm, and position the group-hole workpiece 9 to the bottom end of the frame 6. The group-hole workpiece 9 is 180mm long, 180mm wide, and 1mm thick. There are a total of 81 holes on 9 with a diameter of 5mm.

[0041] The processing conditions of this embodiment are: the size of the magnetic pole disc 20 is 40mm in diameter, 25mm in thickness, magnetic abrasive grains are 60 meshes, the filling volume is 15 grams, the grinding fluid is Laurian SR-991 water-based grinding fluid, and the processing gap is 2mm , Ultrasonic frequency is 20kHz, grinding processing time is 60min.

[0042] During the grinding process, the movement track is a sinusoidal movement. After grinding by the equipment and processing technology of the present invention, the hole exit burr is effectively removed, the surface quality of the workpiece is improved, and the work efficiency is also improved.

Embodiment 2

[0044] In this embodiment, the workpiece material is TC4, the length is 230 mm, the width is 230 mm, the thickness is 1 mm, the number of horizontal holes is 20, the number of longitudinal holes is 20, and the hole diameter is 5 mm. It is required to completely remove the burrs at the edge of the hole and ensure a high surface quality.

[0045] The size of the magnetic pole disc is 40mm in diameter and 25mm in thickness. The magnetic abrasive grains are 60 meshes. The filling volume is 15 grams. The grinding fluid is Laurien SR-991 water-based grinding fluid, the processing gap is 2mm, the ultrasonic frequency is 20kHz, and the grinding processing time is 60min.

[0046] After grinding by the equipment and processing technology of the present invention, the burrs at the exit of the hole are effectively removed, and the surface of the workpiece is uniform, which meets the processing requirements.

[0047] Aiming at the current situation of manual burr removal, the present invention a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com