Enhanced magnesium oxysulfate cement retarder

A technology of magnesium oxysulfide cement and retarder, which is applied in the field of cement admixtures, can solve the problems of reducing cement hydration heat, difficulty in injection molding, and low product strength, so as to improve workability, solve moisture absorption and return halogen, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A novel magnesium oxysulfide cement retarder is prepared from the following raw materials in parts by weight: 0.8 part of gluconic acid, 0.05 part of sodium gluconate, 0.4 part of malonic acid and 0.05 part of succinic acid. The above-mentioned raw materials are mixed and then ground, and the retarder is obtained after the grinding is sufficient.

[0019] Under the condition of a room temperature of 25-40° C., 18 parts of magnesium sulfate are dissolved in 64 parts of tap water to prepare a magnesium sulfate solution. Take 82 parts of magnesium sulfate solution, add the above-mentioned retarder until it dissolves completely, and add it into the mixer together with 100 parts of light-burned magnesium oxide powder, adjust the speed of the mixer to 3000 rpm, and the stirring time is 15 minutes. After stopping stirring, the obtained magnesium oxysulfide cement slurry.

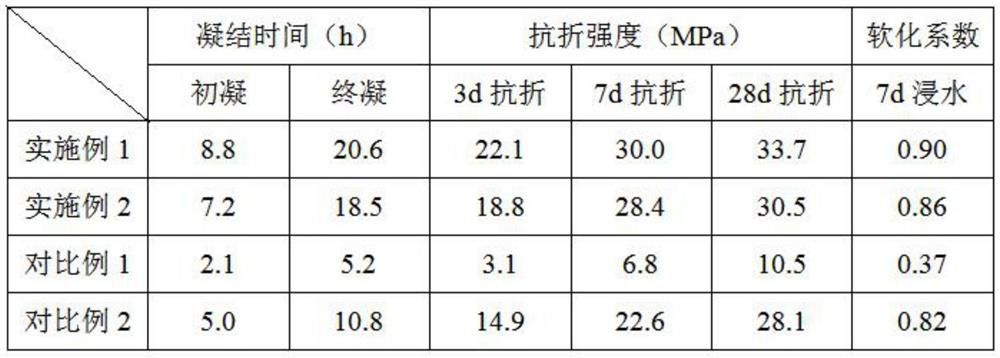

[0020] According to GB / T 1346-2011, the setting time test of the magnesium oxysulfide cement slurry obta...

Embodiment 2

[0022] A novel magnesium oxysulfide cement retarder is prepared from the following raw materials in parts by weight: 1.0 part of gluconic acid, 0.1 part of sodium gluconate, 0.2 part of malonic acid and 0.1 part of succinic acid. The above-mentioned raw materials are mixed and then ground, and the retarder is obtained after the grinding is sufficient.

[0023] A pH meter is used to measure that the setting retarder is at a room temperature of 25-40° C., and 18 parts of magnesium sulfate are dissolved in 64 parts of tap water to prepare a magnesium sulfate solution. Take 82 parts of magnesium sulfate solution, add the above-mentioned retarder until it dissolves completely, and add it into the mixer together with 100 parts of light-burned magnesium oxide powder, adjust the speed of the mixer to 3000 rpm, and the stirring time is 15 minutes. After stopping stirring, the obtained magnesium oxysulfide cement slurry.

[0024] According to GB / T 1346-2011, the setting time test of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com