Clean production method of 1, 4-butanediol diglycidyl ether

A technology of diglycidyl ether and its production method, which is applied in the direction of organic chemistry, can solve the problem of excessive waste water, and achieve the effects of less waste water, simple operation, and reasonable design of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

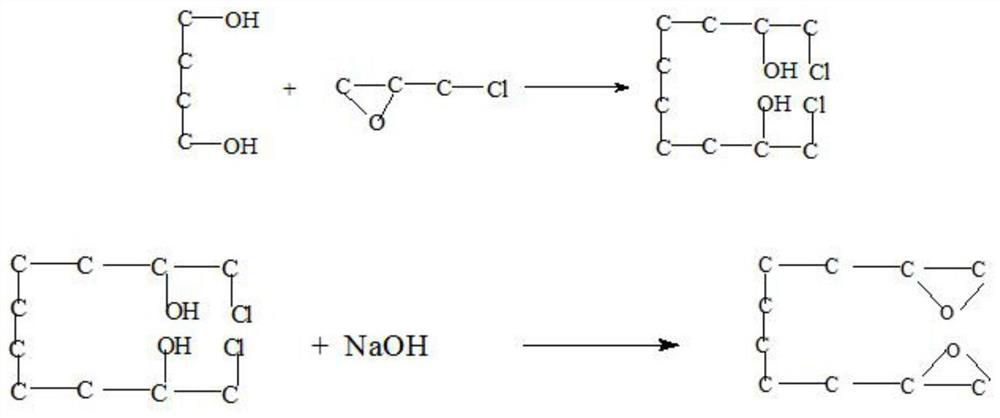

[0024] A kind of preparation method of 1,4-butanediol diglycidyl ether, it comprises the following steps:

[0025] (1) Add 200g of 1,4-butanediol and 1.4g of boron trifluoride-diethyl ether into a 2000ml four-neck flask, add 472.8g of epichlorohydrin dropwise at 70°C under stirring, add dropwise for 3 hours, and keep for 1 Hour;

[0026] (2) Then add 700g of toluene, heat up to 40°C, add 204.4g of solid NaOH, take 4 hours, keep for 1 hour, after the reaction is completed, transfer to a Buchner funnel for suction filtration, add a certain amount of phosphoric acid to the filtrate for neutralization , and then transferred to a separatory funnel for liquid separation. After the liquid separation, the toluene solvent was removed to obtain 484 g of 1,4-butanediol diglycidyl ether, with a yield of 99.5%.

Embodiment 2

[0028] A kind of preparation method of 1,4-butanediol diglycidyl ether, it comprises the following steps:

[0029] (1) Add 200g of 1,4-butanediol and 1.4g of perchloric acid to a 2000ml four-neck flask, add 472.8g of epichlorohydrin dropwise at 70°C under stirring, add dropwise for 3 hours, and keep for 1 hour (after testing Pre-reaction residual epichlorohydrin is more);

[0030] (2) Then add 700g of toluene, the temperature rises to 40°C, add 204.4g of solid NaOH, add for 4 hours, keep for 1 hour after the reaction is completed, transfer to a Buchner funnel for suction filtration, add a certain amount of phosphoric acid to the filtrate for neutralization, and then transfer Separation was carried out in a separating funnel, and the toluene solvent was removed after separation to obtain 390 g of 1,4-butanediol diglycidyl ether, with a yield of 80.2%.

Embodiment 3

[0032] A kind of preparation method of 1,4-butanediol diglycidyl ether, it comprises the following steps:

[0033] (1) Add 200g of 1,4-butanediol and 1.4g of boron trifluoride-ether to a 2000ml four-neck flask, add 472.8g of epichlorohydrin dropwise at 60°C under stirring, add dropwise for 3 hours, and keep for 1 hour ;

[0034] (2) Add 500g toluene, the temperature rises to 40°C, solid NaOH 204.4g, add for 4 hours, keep for 1 hour after the reaction is completed, transfer to the Buchner funnel for suction filtration, add a certain amount of phosphoric acid to the filtrate for neutralization, and then transfer to Separation was carried out in a separatory funnel, and the toluene solvent was removed after separation to obtain 475 g of 1,4-butanediol diglycidyl ether with a yield of 97.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com