Quantum dot and preparation method thereof

A technology of quantum dots and multi-layer shells, applied in chemical instruments and methods, electrical components, nanotechnology, etc., can solve problems such as environmental hazards, high toxicity of quantum dots, and limited application fields, and achieve good thermal stability and high photochemical properties. Stability, the effect of improving quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

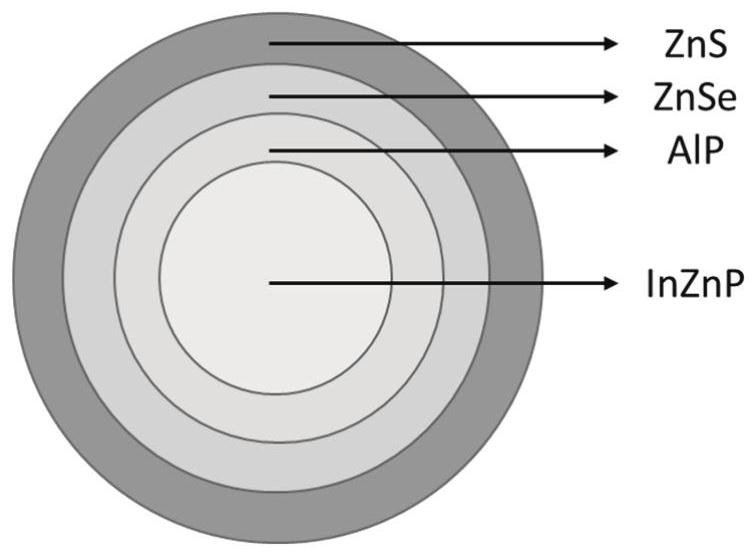

[0090] Example 1: Preparation of InZnP / AlP / ZnSe / ZnS multilayer shell quantum dots

[0091] Fabrication of InZnP cores:

[0092] Put indium iodide (Indium Iodide) 0.45mmol, zinc chloride (zinc chloride) 2.2mmol, oleylamine (oleylamine) 15mmol in a 100mL reactor, heated to 120 ℃ under vacuum for 1 hour, the reactor Converted to nitrogen atmosphere. After heating to about 180°C, a 1.6 mmol solution of tris(dimethylamino)phosphine (DMA3P) was rapidly injected and allowed to react for 5 minutes. Acetone was added to the rapidly cooled reaction solution at room temperature, and the solution was centrifuged. The precipitate obtained after separation is dispersed in cyclohexane or toluene. According to the results of UV spectroscopic analysis of the obtained InZnP semiconductor nanocrystals, the first UV absorption maximum wavelength range is 440nm-480nm.

[0093] Making the first shell of AlP:

[0094] Aluminium oleate was added to the reactor as a precursor for aluminium, wh...

Embodiment 2-6

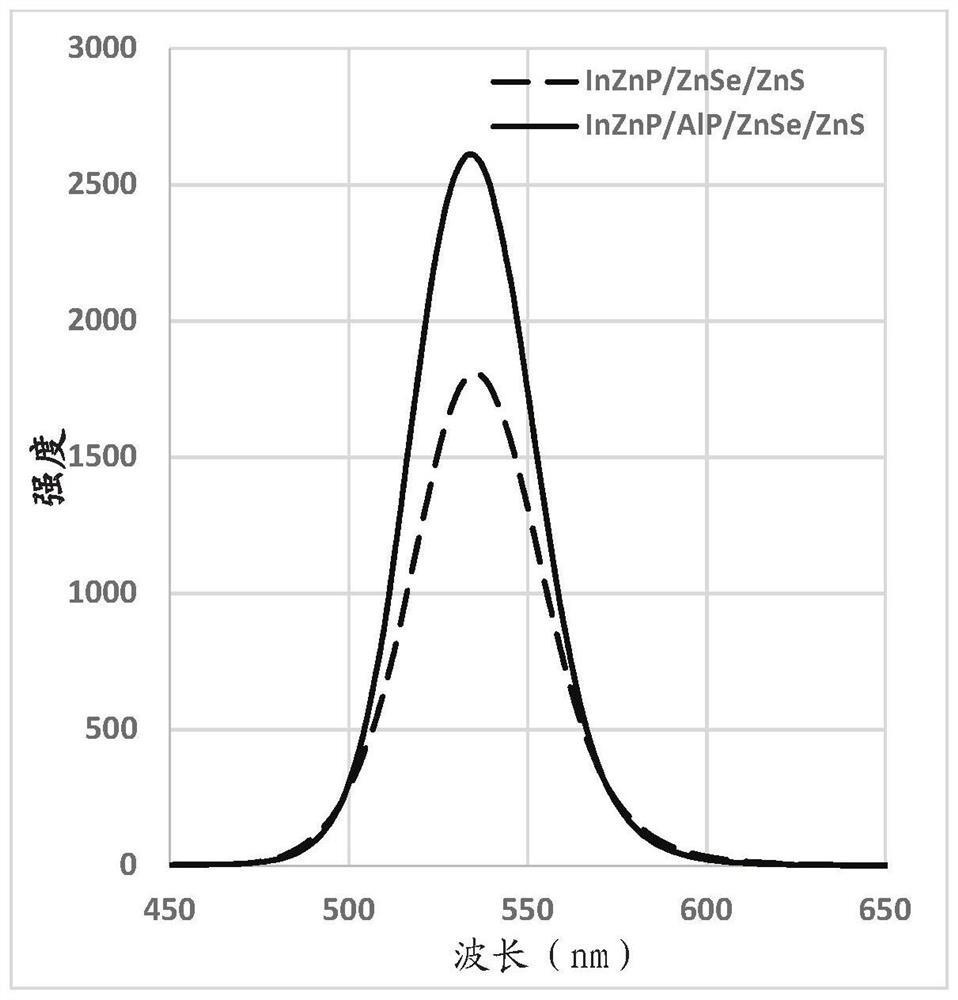

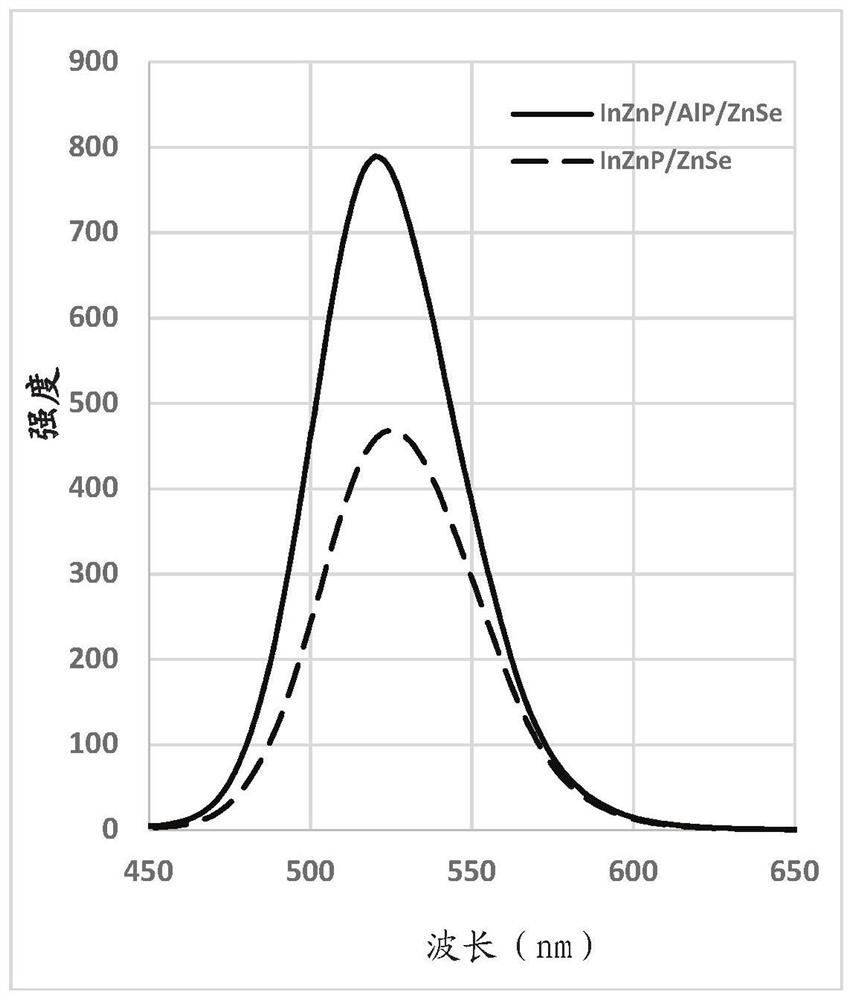

[0105] Experiments were carried out according to the content of aluminum oleate. Synthesis Method Quantum dots were produced in the same manner as in Example 1. The produced quantum dots were analyzed for photoluminescence using excitation light of 365 nm or 458 nm. The results are shown in Table 1 below.

[0106] Table 1.

[0107] Aluminum Oleate Content (mmol) QY(%) FWHM Example 2 0.01 83 45 Example 3 0.02 85 40 Example 4 0.05 87 41 Example 5 0.1 90 39 Example 6 0.2 86 38

[0108] As can be seen from the results in Table 1, it was confirmed that the optical properties of quantum dots can be improved by the synthesis of the aluminum intermediate shell.

Embodiment 7-11

[0110] As the aluminum precursor, quantum dots were produced in the same manner as in Example 1, except that aluminum oleate was replaced with aluminum monostearate at the content shown in Table 2. The produced quantum dots were analyzed for photoluminescence using excitation light of 365 nm or 458 nm. The results are shown in Table 2.

[0111] Table 2.

[0112] Aluminum monostearate content (mmol) QY(%) FWHM Example 7 0.01 80 44 Example 8 0.02 83 45 Example 9 0.05 89 40 Example 10 0.1 86 39 Example 11 0.2 81 42

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com