Lactobacillus sakei and application thereof

A technology of Lactobacillus sake and lactic acid bacteria, applied in the direction of Lactobacillus, application, bacteria, etc., can solve the problems of application limitations of lactic acid bacteria preparations, and achieve the effect of improving utilization rate and good fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Isolation and identification of excellent lactic acid bacteria in spicy cabbage

[0030] 1.1. Separation of lactic acid bacteria:

[0031] Spicy cabbage juice was taken from different parts of multiple portions of spicy cabbage, diluted with 0.9% saline to an appropriate concentration, and spread on MRS agar plates containing 2% calcium carbonate using a sterilized glass triangular rod. The plate is placed in a 37°C incubator for 24h to 72h, and a single colony with a calcium-dissolving circle is picked, and the plate is streaked for separation, and the morphology of the colony is observed and purified.

[0032] 1.2. Preservation of lactic acid bacteria:

[0033] After the purified strain liquid is expanded, add 500μL of 20% glycerin and 500μL of the expanded strain into the sterilized Tube tube. Use an alcohol lamp flame outer flame to burn the tube mouth part and mix it thoroughly. uniform. Mark the number with a marker on the wall and cover of the tube, and seal with pl...

Embodiment 2

[0109] The test was divided into three test groups, R17, CT-10 and NFK-6, each test group was inoculated into MRS broth medium at 3%, cultured at 20℃ for 3 days, and each test group had 3 replicates.

[0110] 1. Research on growth characteristics under different temperature conditions:

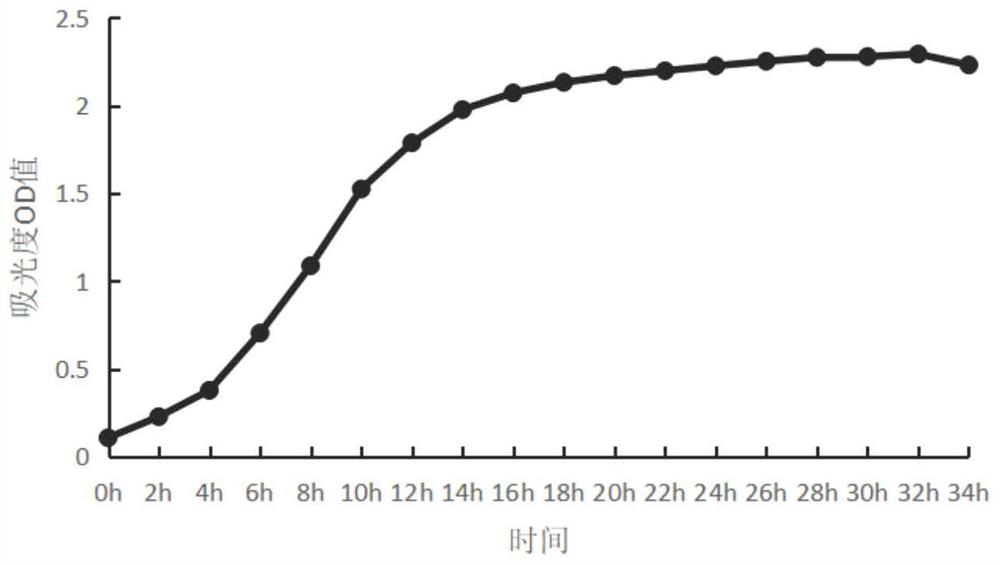

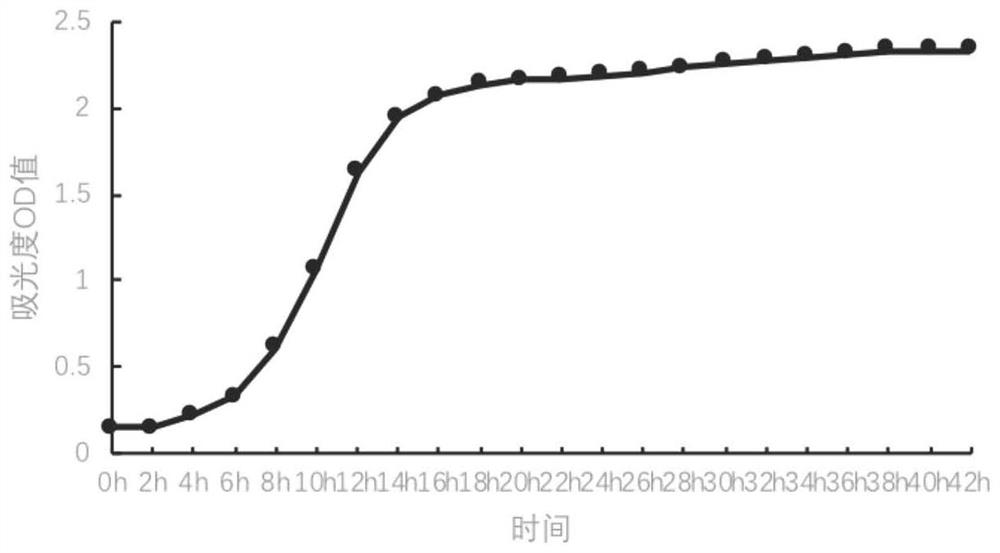

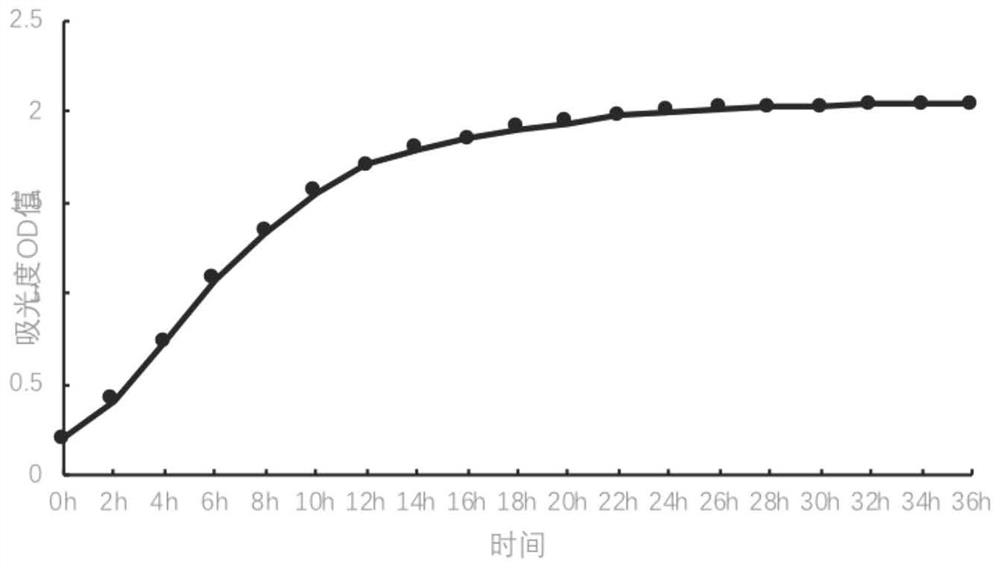

[0111] The R17 and CT-10 strains were activated and inoculated into MRS broth medium at a ratio of 3%, and NFK-6 was directly inoculated into MRS broth medium at a ratio of 3%. The three test groups were placed in an incubator at 37°C. Incubate in medium for 12 hours and dilute to make the number of lactic acid bacteria 10 8 cfU·mL -1 , Inoculate lactic acid bacteria in MRS liquid medium at a ratio of 3%, culture at 20°C for 3 days, and measure the OD value at 600nm.

[0112] 2. Research on acid tolerance of different strains:

[0113] Adjust the pH of the prepared MRS broth medium to 3.0, 3.5, 4.0, 4.5, 5.0, 6.0 with 1mol / L HCl and 1mol / L NaOH solution, and autoclave at 121°C for 20 minutes, and then...

Embodiment 3

[0146] 1. Preparation of TMF

[0147] The corn stalks are cut into about 2 cm with a guillotine knife and then mixed with the fine materials according to the principle of first coarse and then fine. During the mixing process, add appropriate amount of water to control the water content at about 60%. The addition of the bacterial liquid in each test group was diluted with water and sprayed evenly during the mixing process, while the CON group was added with the same amount of deionized water. Put the prepared feed into a numbered fermentation bag, each with a net weight of (2000±1.41) g, seal it with a vacuum packaging machine and store it on a dry indoor floor for fermentation.

[0148] 2. Experimental design

[0149] This test is divided into CON group and 3 test groups. The CON group (control group) is a TMR diet with a fine-to-rough ratio of 6:4 and a moisture content of about 60%. The diet composition and nutritional components are shown in Table 12; the test groups are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com