Instant tea soup extraction production line and use method thereof

A technology for tea and tea soup, applied in the field of instant tea tea soup extraction production line, can solve the problems of low degree of automation, material blocking in the extraction production line, low extraction efficiency, etc., and achieve the effects of complete extraction of tea soup, reduction of content, and reduction of production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

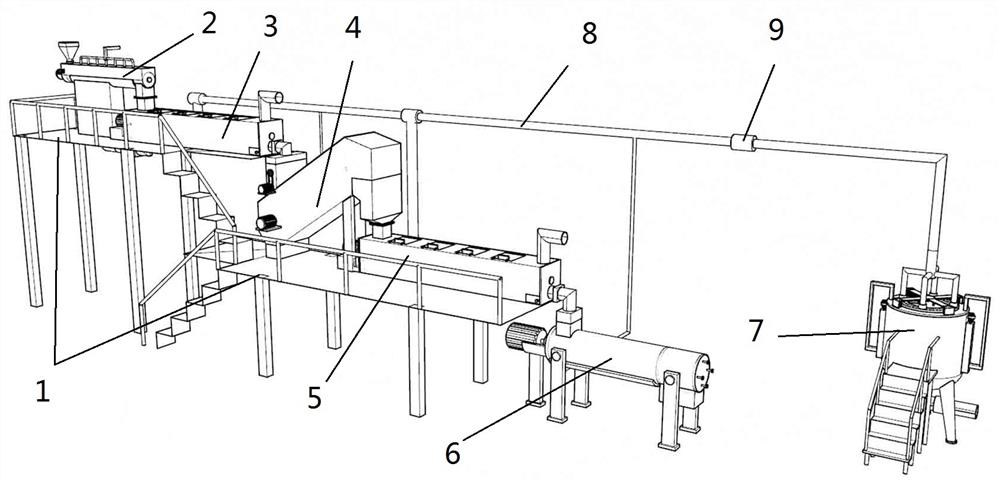

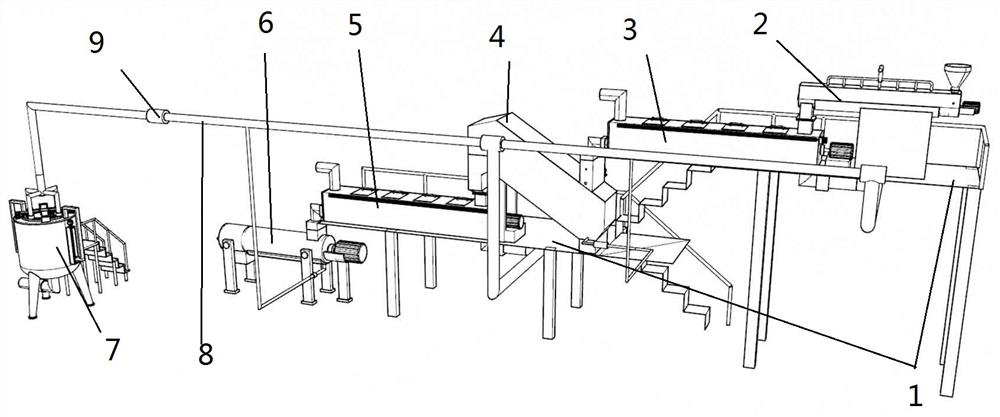

[0034] Such as Figure 1-13 Among them, an instant tea soup extraction production line includes a production line support 1, and the production line support 1 is provided with a pretreatment device 2, a first extraction device 3, a conveying device 4, and a second extraction device that are sequentially connected and assembled. 5 and unloading equipment 6, the tea soup discharge end of the first extracting equipment 3, conveying equipment 4, second extracting equipment 5 and unloading equipment 6 is connected with liquid delivery pipe 8 by pipeline, is provided with water pump on the liquid delivery pipe 8 9. The liquid delivery pipe 8 is connected with the filter and slag removal equipment 7 .

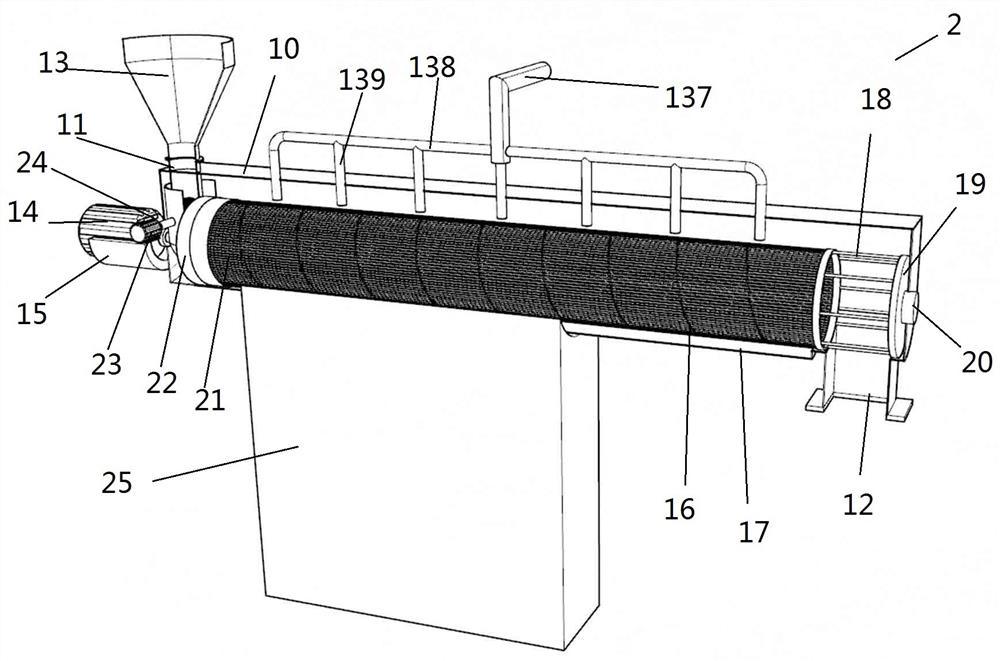

[0035] In a preferred solution, the pretreatment device 2 includes a first feed inlet 11, a first discharge outlet 12, a first collection box 17 and a plurality of water spray pipes 139 on the pretreatment pipe 10, and the first collection The bottom of box 17 is provided with first ...

Embodiment 2

[0042] Such as Figure 1-13 Among them, the usage method of the present invention is:

[0043] 1) The tea raw material enters the pretreatment equipment 2 from the wide-mouth pipe 13, and the hot water enters the pretreatment pipe 10 from the first hot water pipe 137. The tea raw material rotates through the filter barrel cover 21 and is discharged by the spiral blade 16 to the first Port 12 conveying, hot water continuously washes the tea raw materials during the conveying process, reducing the content of caffeine in the tea raw materials;

[0044]2) The tea raw material after removing caffeine enters the second feeding port 35 through the first discharge port 12, and is transported to the second discharge port 35 through the first auger 47. During the transportation, hot water passes through the second feeding port 35. The hot water pipe 38 enters the extraction box 34, and the direction of water flow is opposite to that of the tea raw materials, and the tea soup is extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com