Raw material screening method for paclitaxel production

A screening method and paclitaxel technology are applied in the directions of cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., which can solve the problems of affecting extraction effect, unsatisfactory effect, complicated screening effect, etc., so as to improve the bactericidal effect, The effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

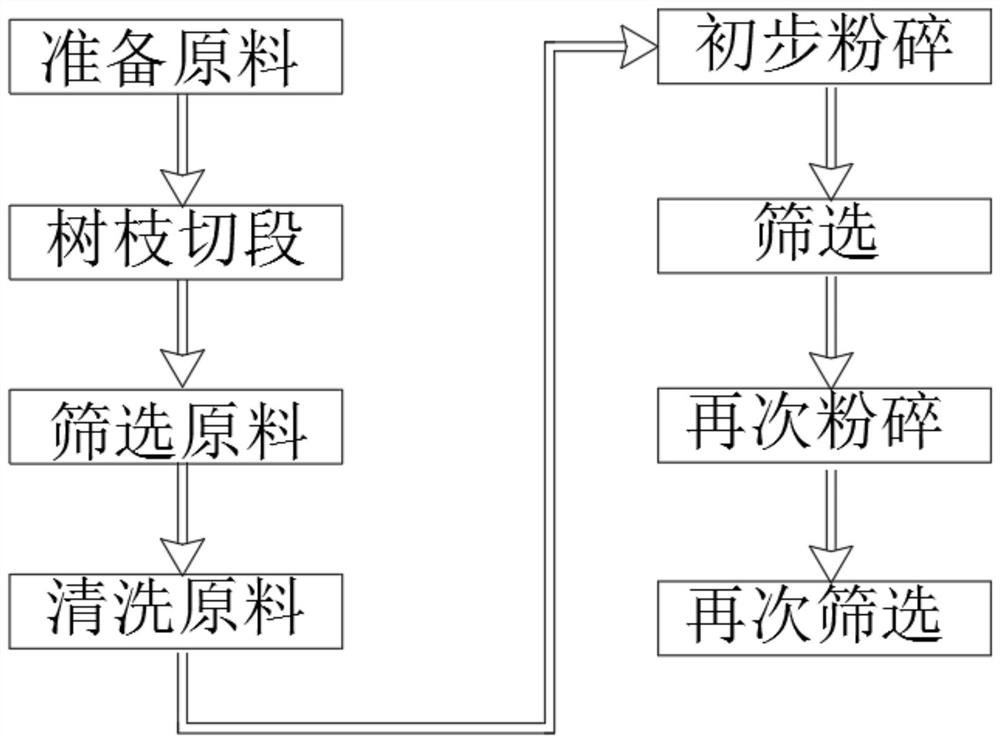

[0032] refer to figure 1 , a raw material screening method for paclitaxel production, comprising the following steps:

[0033] S1: Prepare raw materials, prepare the whole Northeast yew tree, and then perform peeling treatment to distinguish the yew bark, branches and leaves;

[0034] S2: branch cutting, cutting the stripped bark and branches;

[0035] S3: Screening raw materials, removing unqualified bark and branches with insects or corrosion with a knife to prevent unqualified raw materials from polluting paclitaxel during the extraction process and affecting the normal efficacy of the drug;

[0036] S4: Clean the raw materials, put the raw materials to be processed in water, and then dry them naturally, then repeat the cleaning once, and then dry them again to prevent insect eggs or dust invisible to the naked eye from adhering to the raw materials, and then crush them later. The added ethanol will be polluted during the extraction, which will affect the normal reaction;...

Embodiment 2

[0044] refer to figure 1 , a raw material screening method for paclitaxel production, comprising the following steps:

[0045] S1: Prepare raw materials, prepare the whole Northeast yew tree, and then perform peeling treatment to distinguish the yew bark, branches and leaves;

[0046] S2: branch cutting, cutting the stripped bark and branches;

[0047] S3: Screening raw materials, removing unqualified bark and branches with insects or corrosion with a knife to prevent unqualified raw materials from polluting paclitaxel during the extraction process and affecting the normal efficacy of the drug;

[0048] S4: Clean the raw materials, put the raw materials to be processed in water, and then dry them naturally, then repeat the cleaning once, and then dry them again to prevent insect eggs or dust invisible to the naked eye from adhering to the raw materials, and then crush them later. The added ethanol will be polluted during the extraction, which will affect the normal reaction;...

Embodiment 3

[0056] refer to figure 1 , a raw material screening method for paclitaxel production, comprising the following steps:

[0057] S1: Prepare raw materials, prepare the whole Northeast yew tree, and then perform peeling treatment to distinguish the yew bark, branches and leaves;

[0058] S2: branch cutting, cutting the stripped bark and branches;

[0059] S3: Screening raw materials, removing unqualified bark and branches with insects or corrosion with a knife to prevent unqualified raw materials from polluting paclitaxel during the extraction process and affecting the normal efficacy of the drug;

[0060] S4: Clean the raw materials, put the raw materials to be processed in water, and then dry them naturally, then repeat the cleaning once, and then dry them again to prevent insect eggs or dust invisible to the naked eye from adhering to the raw materials, and then crush them later. The added ethanol will be polluted during the extraction, which will affect the normal reaction;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com