Tubular catalytic membrane reactor for selective oxygenation of hydrocarbons

A catalytic membrane reactor and selective oxidation technology, applied in the direction of physical/chemical process catalysts, catalyst carriers, chemical instruments and methods, etc., can solve the problems of reducing the selectivity of the target product, low yield of the target product, and accelerating the reaction. Achieve the effects of easy control of reaction temperature, suppression of side reactions, and avoidance of hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

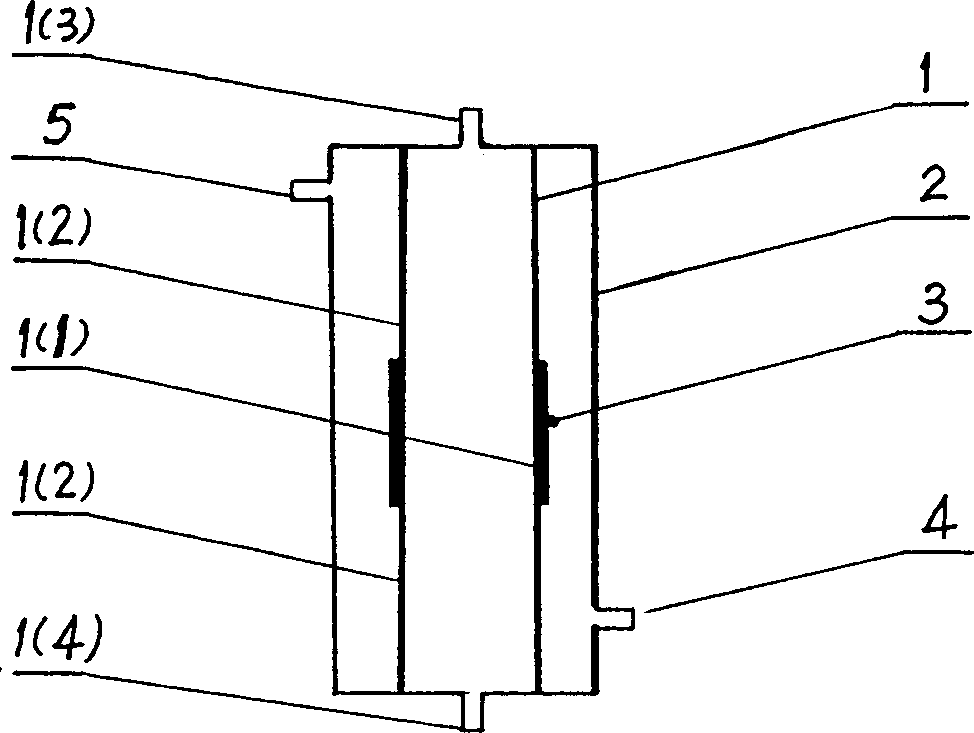

[0025] Such as figure 1 As shown, the tubular catalytic membrane reactor for the selective oxidation of hydrocarbons of the present invention is composed of an outer tube 2 and an inner tube 1, and the two ends of the inner tube and the outer tube can be connected by sealing gaskets and nuts. In this example, copper gaskets and nuts are used to connect . The inner tube 1 is composed of a microporous metal tube 1(1) welded with a non-porous metal tube 1(2), one end of the inner tube is a purge gas inlet 1(3), and the other end is a product outlet 1(4); the microporous The outer surface of the metal tube 1 (1) is coated with a catalytic film layer 3; the two ends of the outer tube 2 are connected with two gas nozzles 4 and 5.

Embodiment 2

[0026] Embodiment 2: Selective oxidation reaction of isobutylene

[0027] Adopt the tubular catalytic membrane reactor of the hydrocarbon selective oxidation of embodiment 1, its outer pipe diameter is 50 millimeters, thickness 5 millimeters, long 300 millimeters, inner pipe diameter is 20 millimeters, thickness 2 millimeters, length is identical with outer pipe; The metal tube is 100mm long.

[0028] Heteropoly compounds for catalysts, composed of H x Cu 0.2 CrPAs 0.6 Mo 12 o y ; Carrier with Ce 0.5 Zr 0.5 o 2 multiple oxides.

[0029] The preparation of the thin film catalyst adopts the rapid spraying method: first spray the precursor solution of Ce-Zr compound oxide on the porous titanium tube, dry it and bake it at 600°C for 3 hours, repeat it several times, and the coating amount is 0.4g. Then spray the concentrated solution of the heteropoly compound on the porous titanium tube loaded with Ce-Zr compound oxide to form a catalyst thin layer. Catalyst film area i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com