Fatty acid modified waterborne alkyd resin and preparation method thereof

A water-based alkyd resin, fatty acid modification technology, applied in coatings, polyester coatings and other directions, can solve the problems of poor water resistance, high cost, poor economic benefits, etc., to increase the density of the paint film, excellent hydrolysis resistance, Good substrate protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

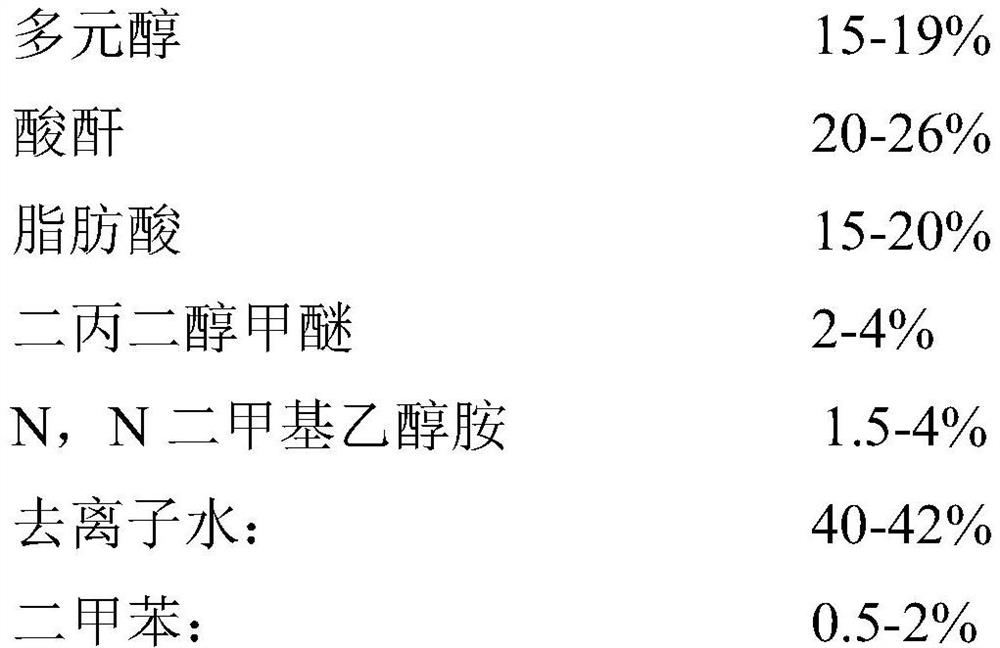

[0032]

Embodiment 2

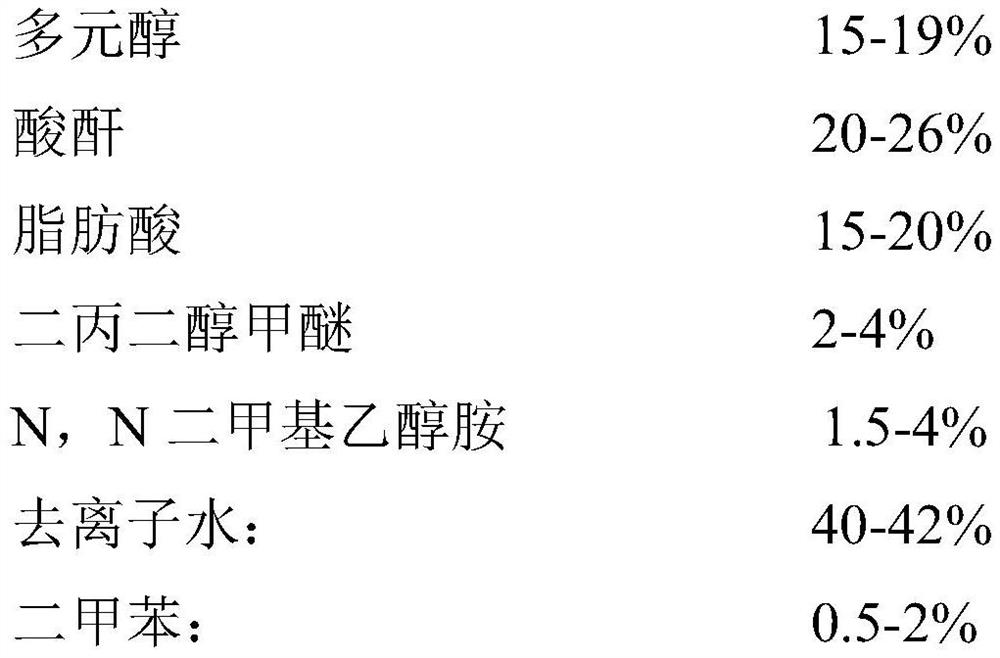

[0034]

Embodiment 3

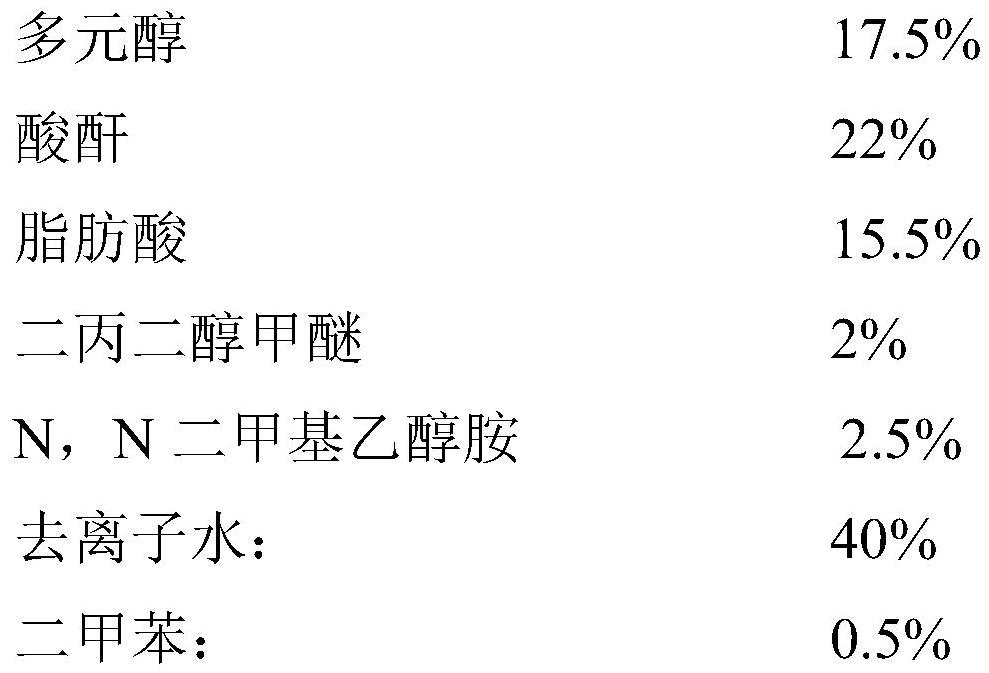

[0036]

[0037] Compared with the water-based alkyd resins currently prepared in the paint industry, the traditional water-based process routes are roughly divided into four types. The traditional preparation methods of water-based alkyd resins are compared with the preparation methods of the present invention:

[0038] Traditional preparation method of waterborne alkyd resin:

[0039] Preparation method 1: In the later stage of the reaction, trimellitic anhydride is introduced as a hydrophilic monomer, and neutralized to form a salt to obtain a water-soluble alkyd resin;

[0040] Preparation method 2: first prepare a water-based alkyd prepolymer, and then prepare a water-based alkyd resin by grafting (meth)acrylic acid monomers and neutralizing to form a salt;

[0041] Preparation method 3. Water-based alkyd resin is prepared by introducing sulfonate monomer (such as isophthalic acid-5-sulfonate) into the polymer chain

[0042] Preparation method 4: First react to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com