Special interface treating agent for smooth building material surface galling, and preparation method thereof

An interface treatment agent, a technology for the surface of building materials, applied in the direction of coating, etc., can solve the problems of difficulty in applying special substrate surfaces, insufficient stability of the pulling layer strength, cumbersome and complicated pulling process, etc., to achieve simple and fast construction, good hair pulling effect, The effect of shortening working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

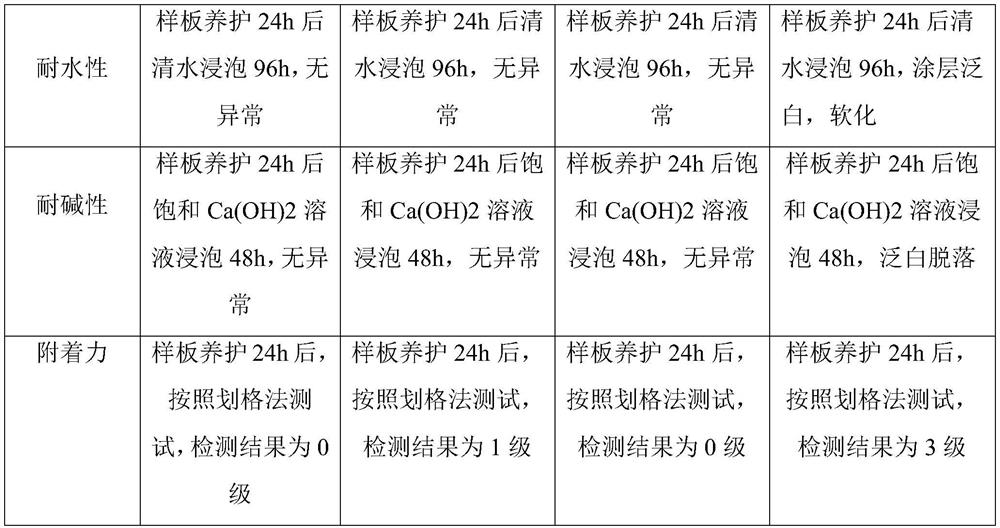

Embodiment 1

[0025] (1) Mix 250 parts of water and 8 parts of Tehao powder in sequence TM 1620, 3 copies of ECOSURF TM Put BD-109 into the container and disperse for 20 minutes, the speed is 800 rpm;

[0026] (2) Put 20 parts of rutile titanium dioxide and 30 parts of 800 mesh calcium carbonate into the container, increase the rotating speed to 1500 rpm, drop into 200 parts of 70-140 mesh river sand, and disperse evenly;

[0027] (3) Then reduce the speed to 800 rpm, add 450 parts of Bailimo to the container TM DC-436, 20 parts of alcohol ester-12TEXANOL, 4 parts of AMP-95, adjust the pH value to 10, reduce the speed to 500 rpm, add 3 parts of BYK-024, after eliminating the foam, add 8 parts of Ya Lesun TM ASE-60, 2 parts of TECTYL 506, 1 part of DOW KATHON LEX, disperse evenly to obtain a special interface treatment agent for roughening the surface of smooth building materials.

[0028] The special interface treatment agent for roughening the surface of smooth building materials prepar...

Embodiment 2

[0030] (1) successively mix 280 mass parts of water, 5 mass parts of special powder TM 1620, 3 parts by mass of ECOSURF TM Put BD-109 into the container and disperse for 20 minutes, and adjust the speed to 800 rpm;

[0031] (2) 10 mass parts of rutile titanium dioxide, 40 mass parts of 800 mesh calcium carbonate are dropped into the container, the rotating speed is increased to 1500 rpm, and 220 mass parts of 70-140 mesh river sand are dropped into, and uniformly dispersed;

[0032] (3) Then reduce the rotating speed to 800 rpm, add 400 mass parts of Bailimo in the container TM DC-436, 10 parts by mass of alcohol ester-12TEXANOL, 5 parts by mass of AMP-95, adjust the pH value to 9, reduce the speed to 500 rpm, add 2 parts by mass of BYK-024, after eliminating foam, add 10 parts by mass Alison TM ASE-60, 5 parts by mass of TECTYL 506, and 1 part by mass of DOW KATHON LEX are uniformly dispersed to obtain a special interface treatment agent for roughening the surface of smoot...

Embodiment 3

[0035] (1) 300 parts by mass of water, 10 parts by mass of special powder TM 1620, 10 parts by mass of ECOSURF TM Put BD-109 into the container and disperse for 20 minutes, and adjust the speed to 800 rpm;

[0036] (2) 10 mass parts of rutile titanium dioxide, 20 mass parts of 800 mesh calcium carbonate are dropped into the container, the rotating speed is increased to 1500 rpm, and 250 mass parts of 70-140 mesh river sand are dropped into, and uniformly dispersed;

[0037] (3) Then reduce the rotating speed to 800 rpm, add 500 mass parts of Bailimo in the container TM DC-436, 40 parts by mass of alcohol ester-12TEXANOL, AMP-95 of 2 parts by mass, adjust the pH value to 9, reduce the speed to 500 rpm, add 5 parts by mass of BYK-024, after eliminating foam, increase the speed to 800 rpm, add 5 parts by mass of Yale Shun TM ASE-60, 1 part by mass of TECTYL 506, and 2 parts by mass of DOW KATHON LEX are uniformly dispersed to obtain a special interface treatment agent for smoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com