Tm<3+> self-activated laser crystal and preparation method thereof

A laser crystal, self-activation technology, applied in the direction of lasers, crystal growth, laser components, etc., to achieve the effect of increasing concentration, improving laser efficiency, and reducing laser threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

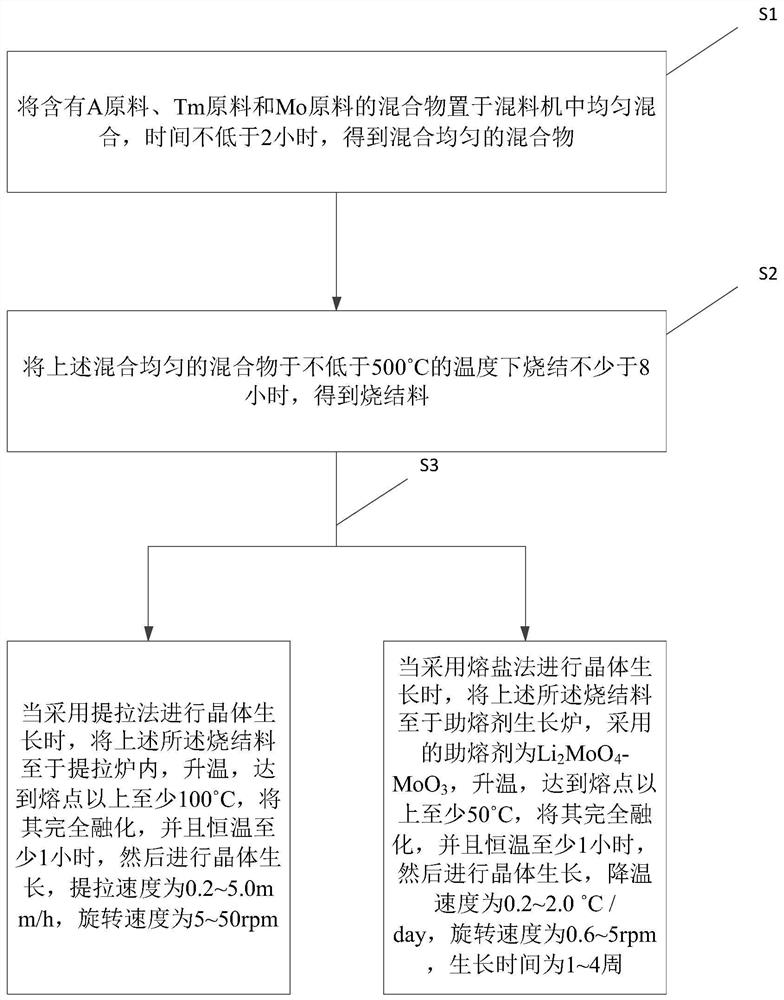

Method used

Image

Examples

Embodiment 1

[0028] This embodiment discloses a Tm 3+ Self-activated laser crystal ATm(MoO 4 ) 2 , wherein A is selected from at least one of Li, Na and K elements, and, Tm 3+ The ions have a dual role, on the one hand, as activating luminescent ions, on the other hand, as a part of the crystal matrix, thereby greatly increasing its concentration, which is beneficial to Tm 3+ 2 micron fluorescence emission of ions, lowering lasing threshold and increasing laser efficiency. The crystal can be grown by pulling method or molten salt method. Using this kind of crystal as a gain medium and pumping with a semiconductor laser with a central emission wavelength of 760-810nm can achieve high-efficiency infrared laser output near 2 microns, which has important application prospects in medical, scientific research, and military fields.

Embodiment 2

[0030] This embodiment discloses a LiTm(MoO 4 ) 2 Self-activated laser crystals and their growth by pulling method.

[0031] high purity Li 2 CO 3 , Tm 2 o 3 , MoO 3 The raw materials are mixed according to the molar ratio Li:Tm:Mo=1:1:2.1 to form a mixture, and the mixture is placed on a mixer for mixing. The mixing time is 12 hours, and it becomes a uniform powder. Under the pressure of 3Gpa Press it into a cylindrical block with a diameter of 50mm, then put the block into a muffle furnace for sintering, the sintering temperature is 500°C, and the sintering time is 25 hours, and then put the sintered block into a platinum with a diameter of 60mm Put the crucible into the pulling furnace for crystal growth, raise the temperature to 50°C above the melting point, keep the temperature for 2 hours, completely melt the block, and then keep the temperature for 3 hours, the temperature field is constant, and then slowly drop the seed crystal into the melt, Start crystal growt...

Embodiment 3

[0033] This embodiment discloses a NaTm(MoO 4 ) 2 Self-activated laser crystals and their growth by pulling method.

[0034] high purity Na2 CO 3 , Tm 2 o 3 , MoO 3 The raw materials are mixed according to the molar ratio Na:Tm:Mo=1:1:2.2 to form a mixture, and the mixture is placed on a mixer for mixing. The mixing time is 15 hours, and it becomes a uniform powder. Under the pressure of 4Gpa Pressed into a cylindrical block with a diameter of 50mm, and then put the block into a muffle furnace for sintering, the sintering temperature is 520°C, and the sintering time is 30 hours, and then the sintered block is put into a platinum plate with a diameter of 60mm Put the crucible into the pulling furnace for crystal growth, raise the temperature to 50°C above the melting point, keep the temperature for 1 hour, completely melt the block, and then keep the temperature for 2 hours, the temperature field is constant, and then slowly drop the seed crystal into the melt, Start crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com