Waste incineration boiler of fire grate type circulating fluidized bed and working method thereof

A circulating fluidized bed and waste incineration technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of high operating cost, unstable feeding and combustion, and large amount of fly ash, so as to avoid insufficient combustion situation, solve combustion instability, and improve the effect of operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

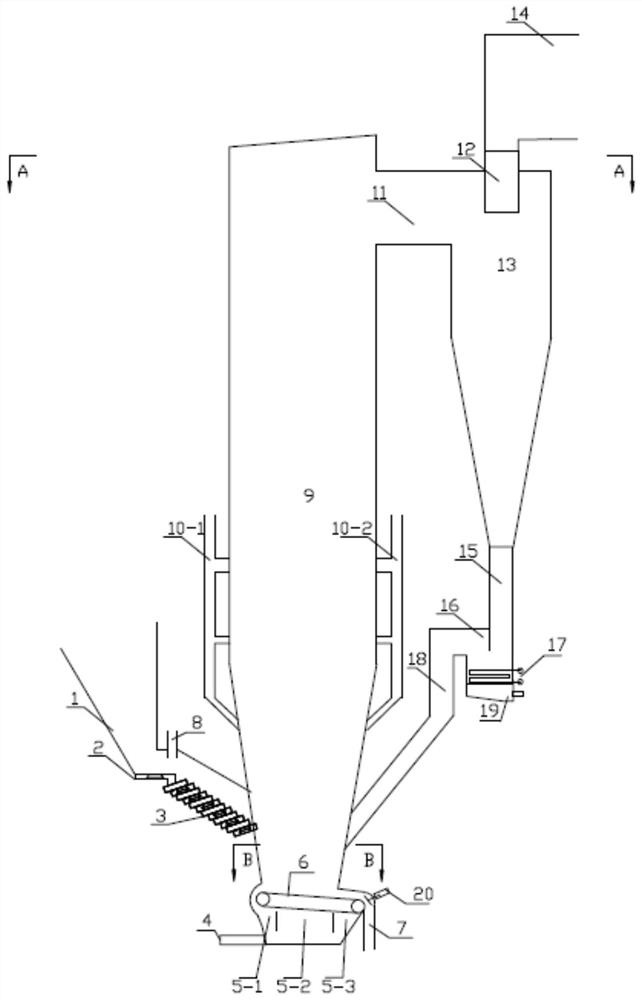

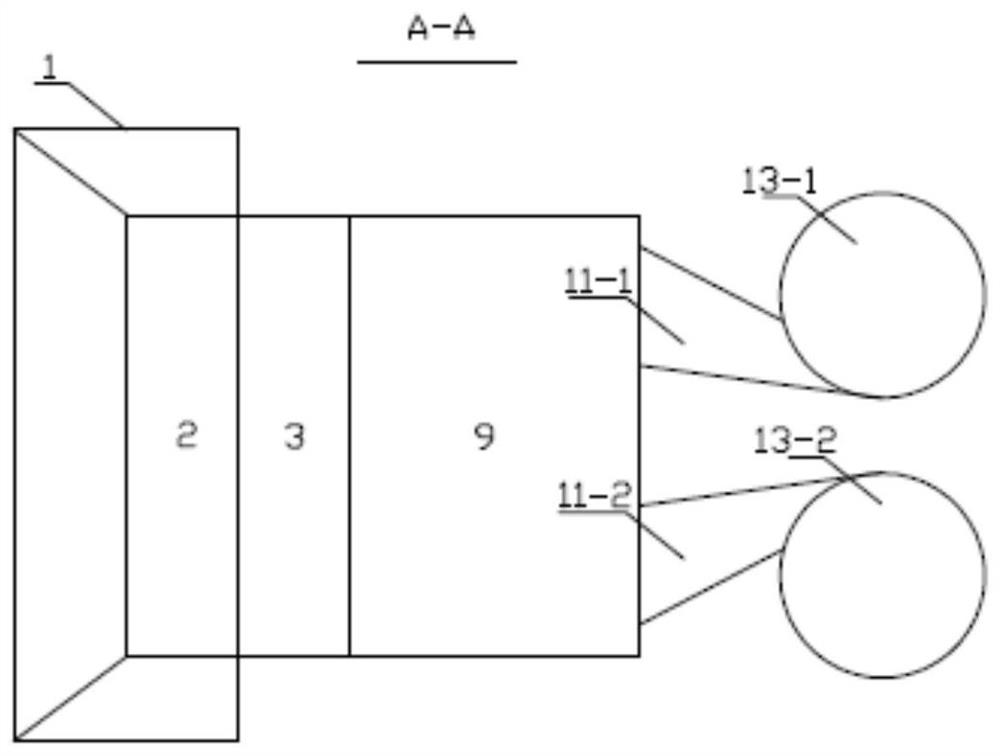

[0038] A grate type circulating fluidized bed waste incineration boiler of the present invention, such as figure 1 , the front feed bin 1 of the boiler is connected with the feeding device 2, the feeding device 2 is connected with the feeding grate 3, the feeding device 2 can adopt a horizontal reciprocating push plate machine, and the feeding grate 3 can adopt an inclined reciprocating grate . The end of the feeding grate 3 is connected to the boiler feed port. The boiler feed port can be provided with a heavy material feed port and a light material feed port respectively. The height of the light material feed port is greater than the height of the heavy material feed port, and the waste material After the pre-order weight sorting, it enters into two feeding ports through different feeding systems. Preferably, the feed grate 3 is arranged in a closed space, and the inlet of the feed grate 3 is connected with a feed air duct 8 .

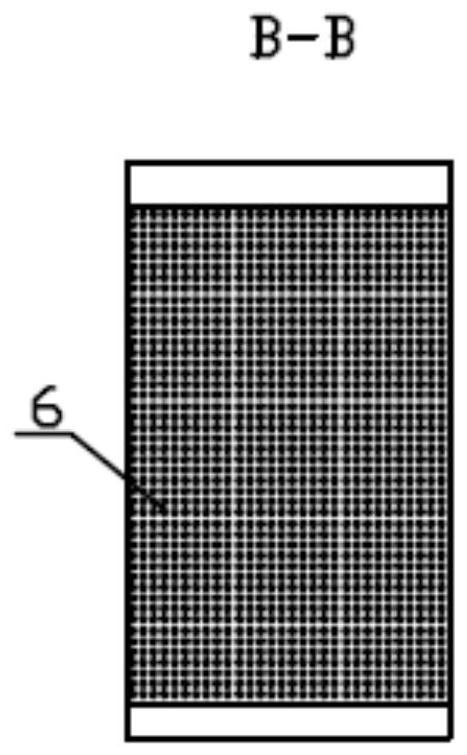

[0039] Conveyor grate 6 can adopt various mo...

Embodiment 2

[0044] Such as Figure 4 , compared with Example 1, the grate-type circulating fluidized bed waste incineration boiler conveying grate 6 of this embodiment is a compact layout, a set of return system is provided, and a separate air chamber 5 is used for air distribution. The ash and slag directly fall into the slag discharge pipe 7 under the transmission action of the conveying grate 6. A mechanical seal is designed between the conveying grate 6 and the furnace 9, and the feeding sealing air pipe 8 and the slag discharge baffle 20 are omitted. . The rest of the components and their connection methods are the same as those in Embodiment 1, and are suitable for situations where the amount of slag is small.

[0045] Below in conjunction with the working method of embodiment 1, the present invention is further explained:

[0046] Domestic garbage is sent into the front feed bin 1 of the boiler by the domestic garbage fuel grab, and then enters the range of action of the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com