Preparation method of ultrathin carbon-coated tin dioxide nano composite material

A nanocomposite material, tin dioxide technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of electrode materials, cycle performance and high discharge capacity, etc., to shorten the diffusion Distance, excellent magnification performance, effect of improving magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preparation method of ultra-thin carbon-coated tin dioxide nanocomposite material, the specific steps are as follows:

[0015] Weigh 0.018mol of tin tetrachloride, 1mol of glucose and 3mg of naphthalene dissolved in 60mL of deionized water, then add 0.8mL of hydrochloric acid, stir magnetically for 30min, put the resulting mixed solution in a kettle, put it in a blast drying oven at 180°C for water Thermal reaction, the reaction time is controlled at 12h. After the hydrothermal reaction product is centrifugally cleaned, it is placed in a blast drying oven for drying.

[0016] Then, the product obtained by the hydrothermal reaction was placed in a tube furnace, heat-treated in a nitrogen atmosphere, heated to 500°C at a heating rate of 5°C / min, and held for 4h, thereby obtaining an ultra-thin carbon-coated tin dioxide nanocomposite material .

[0017] Research results of ultra-thin carbon-coated tin dioxide nanocomposites:

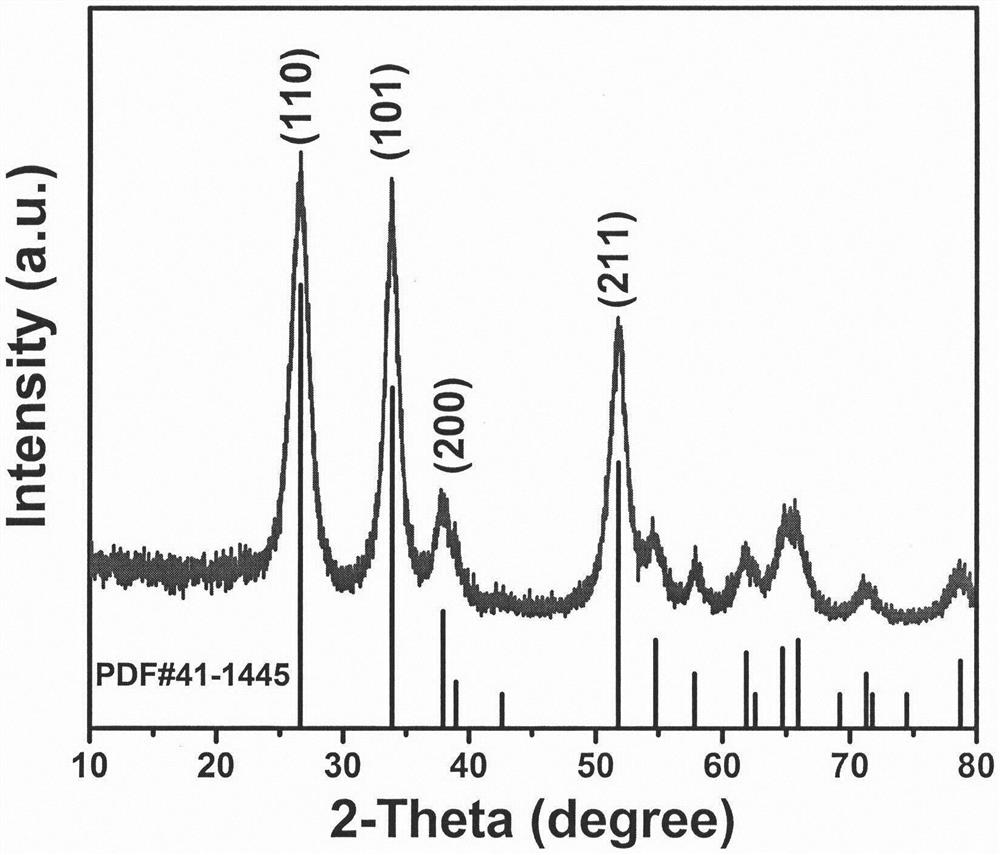

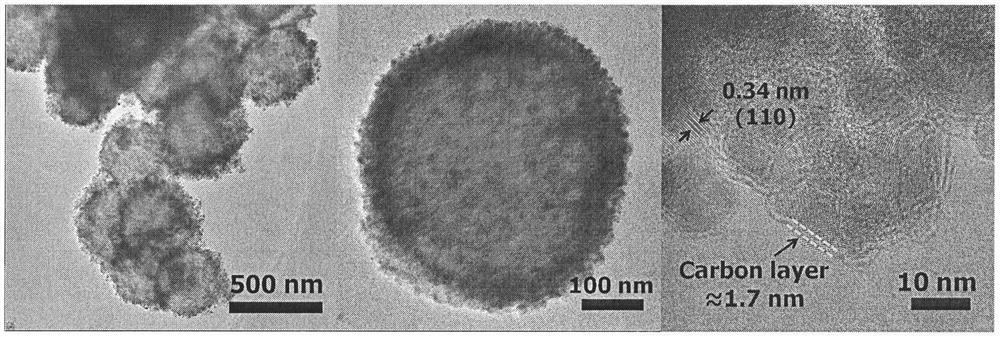

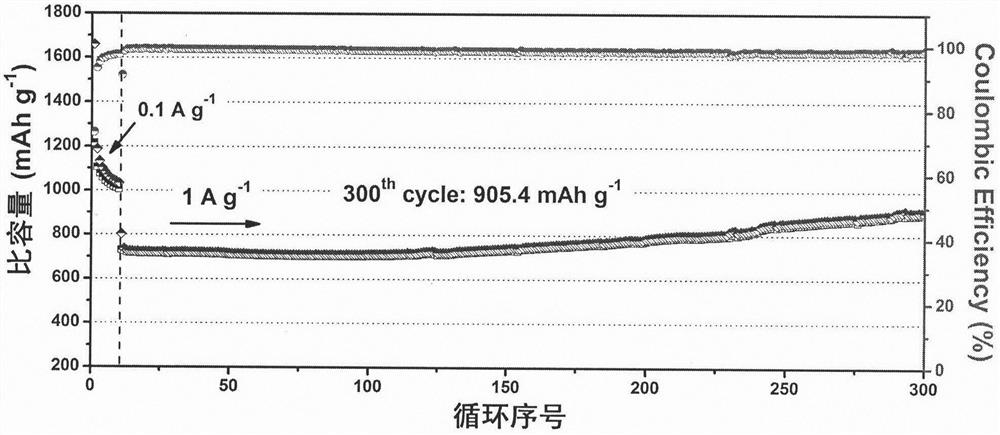

[0018] (1) Material structure analysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com