Titanium-based catalyst doped NaAlH4 composite hydrogen storage system and preparation method thereof

A catalyst, titanium-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of reducing the reversible hydrogen storage capacity of the catalytic system, achieve low cost, increase hydrogen storage capacity, Response to controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

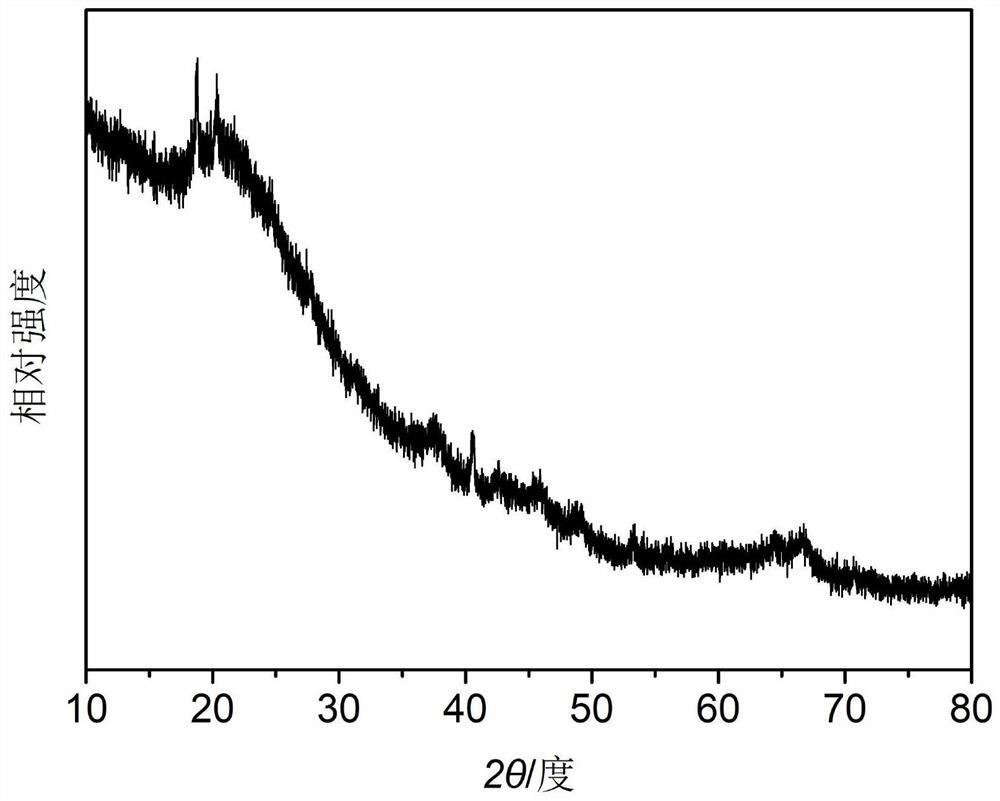

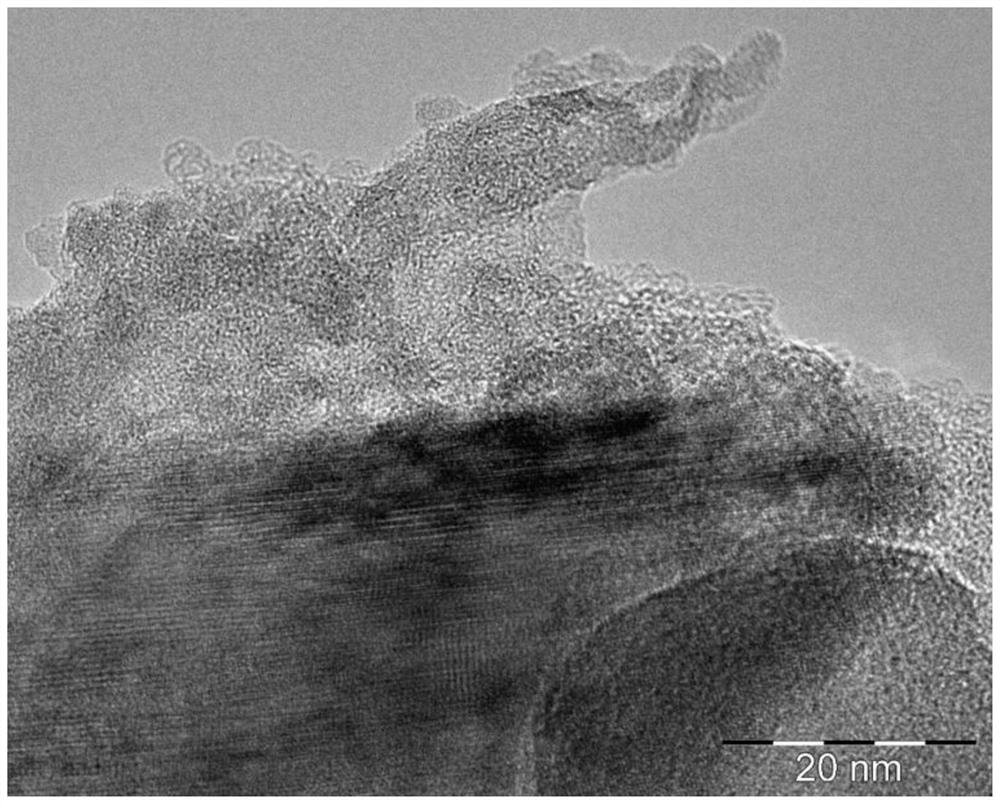

[0031] TiAl 3 The preparation method of @C catalyst:

[0032] Will Cp 2 TiCl 2 and LiAlH 4 After mixing according to the ratio of 1:3, ball milled on a planetary ball mill for 3 hours at a speed of 200 rpm, and the obtained composite was sintered at 400°C for 3 hours under the protection of an argon atmosphere, and then slowly cooled to room temperature. After the above product was washed three times with absolute ethanol, it was vacuum-dried at 140 °C for 6 h to obtain the final TiAl 3 @C Catalyst, see attached figure 1 .

Embodiment 1

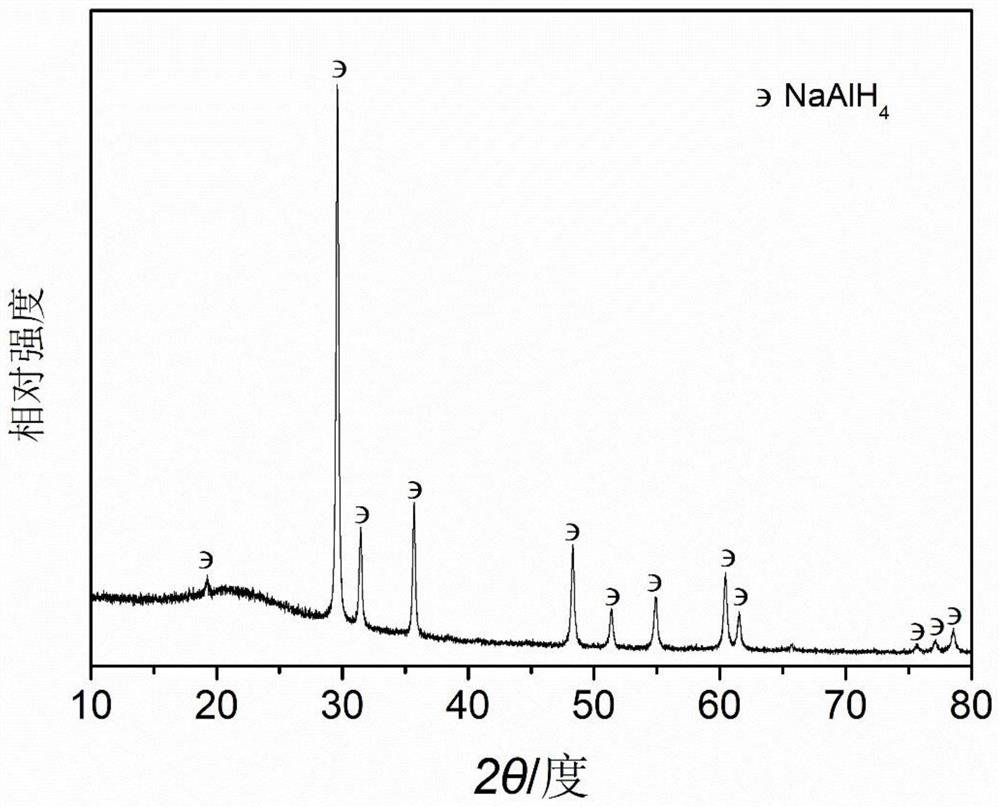

[0034] In a glove box protected by an argon atmosphere, the NaAlH 4 and TiAl 3 @C According to the chemical composition x(NaAlH 4 )-y(TiAl 3 The percentage of @C) was mixed (x=2wt%, y=98wt%). Put the above mixture in a ball mill tank, fill it with 2MPa hydrogen, and then put it into a planetary ball mill with a ball-to-material ratio of 40:1 and a rotation speed of 400rpm. The program is set to stop for 10 minutes every 30 minutes of ball milling, and mill for 20 hours to obtain TiAl 3 @C catalyzed NaAlH4 Composite hydrogen storage system.

Embodiment 2

[0036] In a glove box protected by an argon atmosphere, the NaAlH 4 and TiAl 3 @C According to the chemical composition x(NaAlH 4 )-y(TiAl 3 The percentage of @C) was mixed (x=2wt%, y=98wt%). Put the above mixture in a ball mill tank, fill it with 4MPa hydrogen, and then put it into a planetary ball mill with a ball-to-material ratio of 40:1 and a rotation speed of 400rpm. The program is set to stop for 10 minutes every 30 minutes of ball milling, and mill for 10 hours to obtain TiAl 3 @C catalyzed NaAlH 4 Composite hydrogen storage system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com