Reinforcing admixture for premixed high-flow-state pervious concrete and preparation method of reinforcing admixture

A technology of permeable concrete and high fluidity, applied in the field of concrete admixtures, can solve the problems that limit the promotion and development of ready-mixed permeable concrete, and achieve the effects of increasing the construction time, improving the utilization rate, and improving the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

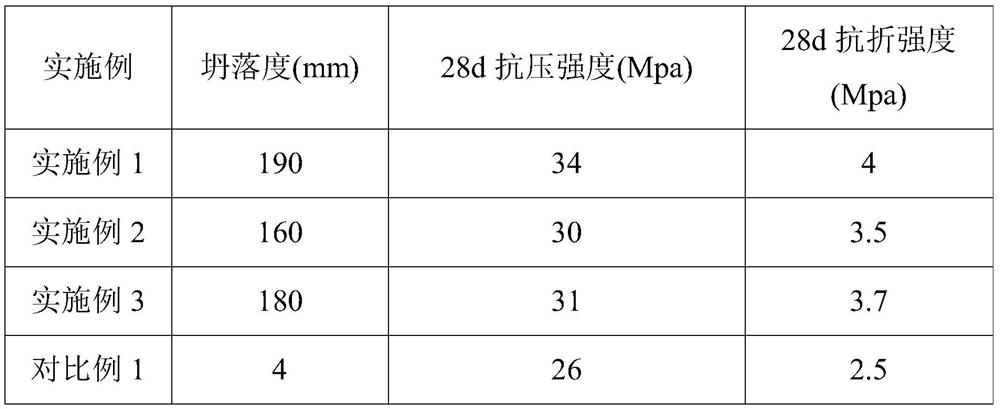

Examples

Embodiment 1

[0023] A reinforcing admixture for ready-mixed high-fluid permeable concrete, including the following components: nano-silica microspheres, vitrified microspheres, water-soluble polymers, water-based blocked polyisocyanates, water-reducing agents, soluble Organic iron salts, air-entraining agents, retarders, and early strength agents; among them, nano-silica microspheres, vitrified microspheres, water-soluble polymers, water-based blocked polyisocyanates, water-reducing agents, and soluble organic iron salts , the mass ratio of air-entraining agent, retarder and early strength agent is 60:10:0.2:5:5:2:0.1:0.5:1;

[0024] The above water-based blocked polyisocyanate is a non-ionic water-based blocked polyisocyanate with an NCO content of 5%, a pH of 6 and a viscosity of 250 mPa.s. In practice, water-based blocked polyisocyanate with an NCO content of 5-6.2% can effectively cross-link and solidify each other without causing the reaction speed to be too fast and too violent. A pH...

Embodiment 2

[0037] A reinforcing admixture for ready-mixed high-fluid permeable concrete, including the following components: nano-silica microspheres, vitrified microspheres, water-soluble polymers, water-based blocked polyisocyanates, water-reducing agents, soluble Organic iron salts, air-entraining agents, retarders, and early strength agents; among them, nano-silica microspheres, vitrified microspheres, water-soluble polymers, water-based blocked polyisocyanates, water-reducing agents, and soluble organic iron salts The mass ratio of air-entraining agent, retarder and early strength agent is 65:15:1:5:9:3:0.2:0.8:1;

[0038] The above water-based blocked polyisocyanate is a non-ionic water-based blocked polyisocyanate with an NCO content of 5.5%, a pH of 7, and a viscosity of 350 mPa.s.

[0039] The deblocking temperature of the above water-based blocked polyisocyanate is 65°C.

[0040]Above-mentioned nano-silica microbead comprises one or more in fumed silica, precipitated silica an...

Embodiment 3

[0051] A reinforcing admixture for ready-mixed high-fluid permeable concrete, including the following components: nano-silica microspheres, vitrified microspheres, water-soluble polymers, water-based blocked polyisocyanates, water-reducing agents, soluble Organic iron salts, air-entraining agents, retarders, and early strength agents; among them, nano-silica microspheres, vitrified microspheres, water-soluble polymers, water-based blocked polyisocyanates, water-reducing agents, and soluble organic iron salts The mass ratio of air-entraining agent, retarder and early strength agent is 70:20:1.2:6:10:3:0.2:2:5;

[0052] The above water-based blocked polyisocyanate is a non-ionic water-based blocked polyisocyanate with an NCO content of 6.2%, a pH of 8, and a viscosity of 400 mPa.s.

[0053] The deblocking temperature of the above-mentioned aqueous blocked polyisocyanate is 75°C.

[0054] Above-mentioned nano-silica microbead comprises one or more in fumed silica, precipitated s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com