Method for utilizing high-boiling-point glycerol asphalt generated by rectification in production process of epoxy chloropropane

A technology of epichlorohydrin and production process, which is applied in the field of utilization of epichlorohydrin production waste, can solve the problems of reducing hazardous waste disposal and high cost, and achieves reducing hazardous waste disposal, enhancing waterproofness, and making up for pinholes or air bubbles. The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

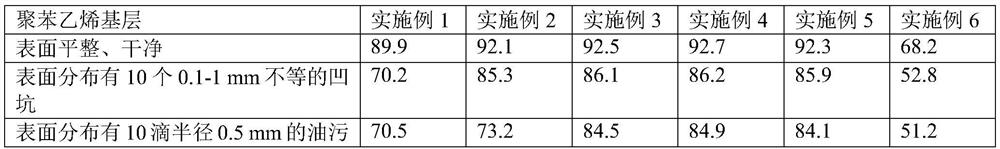

Examples

Embodiment 1

[0021] A method for utilizing the high-boiling glycerol asphalt produced by rectification in the production process of epichlorohydrin, comprising the following steps:

[0022] (1) Get the rectification high boiler produced after the rectification and refining of the product dichloropropanol rectification and refining of the glycerol method to produce epichlorohydrin in the chlorination reaction stage, and distill at 140° C. to obtain high-boiling glycerol asphalt;

[0023] (2) In parts by weight, take 50 parts of glycerol pitch, 10 parts of isocyanate, and 40 parts of heavy calcium, mix them uniformly, stir and react at 70°C for 3 hours, then add 15 parts of epichlorohydrin and react at 100°C for 2 hours to obtain a reaction mixture;

[0024] (3) After cooling the reaction mixture to 50°C, add 8 parts of plasticizer dibutyl phthalate, 20 parts of filler quartz powder, 0.1 part of auxiliary polydimethylsiloxane defoamer and 30 parts of solvent toluene The parts are stirred eve...

Embodiment 2

[0026] (1) Get the rectification high boiler produced after the rectification and refining of the product dichloropropanol rectification and refining of the glycerol method to produce epichlorohydrin in the chlorination reaction stage, and distill at 130° C. to obtain high-boiling glycerol pitch;

[0027] (2) In parts by weight, take 50 parts of glycerol pitch, 20 parts of isocyanate, and 50 parts of heavy calcium, mix them evenly, stir and react at 60°C for 5 hours, then add 10 parts of epichlorohydrin and react at 90°C for 2 hours to obtain a reaction mixture;

[0028] (3) After cooling the reaction mixture to 60°C, add 5 parts of plasticizer butyl benzyl phthalate, 17 parts of filler bentonite, 0.1 part of auxiliary agent isophorone leveling agent and 20 parts of solvent ethyl acetate and stir Evenly, defoam under the vacuum condition of -0.09MPa for 30 minutes, discharge the material, and prepare polyurethane waterproof coating, which can be applied by scraping or spraying....

Embodiment 3

[0030] (1) Get the rectification high boiler produced after the rectification and refining of the product dichloropropanol rectification and refining of the glycerol method to produce epichlorohydrin in the chlorination reaction stage, and distill at 150° C. to obtain high-boiling glycerol asphalt;

[0031] (2) In parts by weight, take 50 parts of glycerol pitch, take 50 parts of dehydrated glycerol pitch, mix with 15 parts of isocyanate and 45 parts of heavy calcium, stir and react at 100°C for 1h, then add 12 parts of epichlorohydrin at 80°C Reaction 3h, obtains reaction mixture;

[0032] (3) After cooling the reaction mixture to 70°C, add 10 parts of plasticizer dibutyl phthalate, 15 parts of filler bentonite and modified bentonite, 2 parts of auxiliary polyacrylamide dispersant and 25 parts of solvent toluene Stir evenly and discharge the material to obtain a polyurethane waterproof coating, which can be applied by scraping or spraying. Wherein the mass ratio of bentonite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com