Composite steering micelle acidifying blockage removing liquid and preparation method thereof

A sour-acid and micelle technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor slowing effect of temperature difference, influence on steering ability, short validity period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

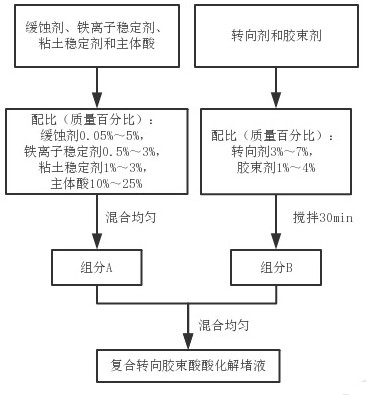

Method used

Image

Examples

Embodiment 1

[0027] The compound diverting micellar acid acidification plugging solution of this embodiment is composed of the following raw materials by mass percentage: 15% hydrochloric acid, 3% oleic acid amidopropyl hydroxy sultaine, 2% cocamidopropyl amine oxide, 0.5% Oleic acid hydroxyethyl imidazoline, 1% citric acid, 0.5% choline chloride, the balance is water.

[0028] Specific preparation process.

[0029] According to the above proportion, oleic acid hydroxyethyl imidazoline, citric acid, choline chloride and hydrochloric acid are mixed evenly, and the balance is water to prepare component A.

[0030] Mix oleic acid amidopropyl hydroxy sultaine and cocamidopropyl amine oxide evenly, stir for 30 minutes, and prepare component B.

[0031] Mix component B and component A uniformly to obtain compound steering micellar acid acidification plugging solution.

[0032] Wherein, the mass concentration of hydrochloric acid is 31%, and the mass concentration of hydrofluoric acid is 40%. ...

Embodiment 2

[0034] The compound diverting micellar acid acidification deblocking solution of this embodiment is composed of the following raw materials by mass percentage: 10% hydrochloric acid, 4% hydrofluoric acid, 4% oleic acid amidopropyl hydroxy sultaine, 2% N,N- Dimethyl-N-octadecyloxymethylene betaine, 3% erucamidopropylamine oxide, 0.5% oleyl hydroxyethyl imidazoline, 0.5% cocoyl amphoteric imidazoline, 0.5% ethyl Disodium diamine tetraacetate, 1% choline chloride, and the balance is water.

[0035] Specific preparation process.

[0036] According to the above ratio, mix oleic acid-based hydroxyethyl imidazoline, coco-based amphoteric imidazoline, disodium edetate, choline chloride, hydrochloric acid and hydrofluoric acid, and mix the balance with water to prepare Component A.

[0037] Mix oleic acid amidopropyl hydroxy sultaine, N,N-dimethyl-N-octadecyloxymethylene betaine and erucic acid amidopropyl amine oxide evenly, stir for 30 minutes, and prepare components b.

[0038] ...

Embodiment 3

[0041] The compound diverting micellar acid acidification plugging solution of this embodiment is composed of the following raw materials by mass percentage: 12% hydrochloric acid, 3% hydrofluoric acid, 3% oleic acid amidopropyl hydroxy sultaine, 2% N,N- Dimethyl-N-Octadecyloxymethylene Betaine, 2% Erucamidopropylamine Oxide, 1% Cocamidopropylamine Oxide, 0.5% Oleyl Hydroxyethylimidazoline, 0.5% Coco-based amphoteric imidazoline, 1% citric acid, 1% choline chloride, and the balance is water.

[0042] Specific preparation process.

[0043] According to the above proportions, oleic acid-based hydroxyethyl imidazoline, cocoyl amphoteric imidazoline, citric acid, choline chloride, hydrochloric acid and hydrofluoric acid are uniformly mixed, and the balance is water to prepare component A.

[0044] Mix Oleamidopropyl Hydroxysultaine, N,N-Dimethyl-N-octadecyloxymethylene Betaine, Cocamidopropylamine Oxide and Erucamidopropylamine Oxide evenly , stirred for 30 minutes, and formulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com