Degradable intravascular stent made of zinc-based alloy material and preparation method thereof

A vascular stent and alloy material technology, which is applied to the field of degradable vascular stents made of zinc-based alloy materials and their preparation, can solve the problems of biological inflammation, biomechanical incompatibility, and inability to degrade, so as to solve the problems of insufficient mechanical properties, Moderate degradation rate and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

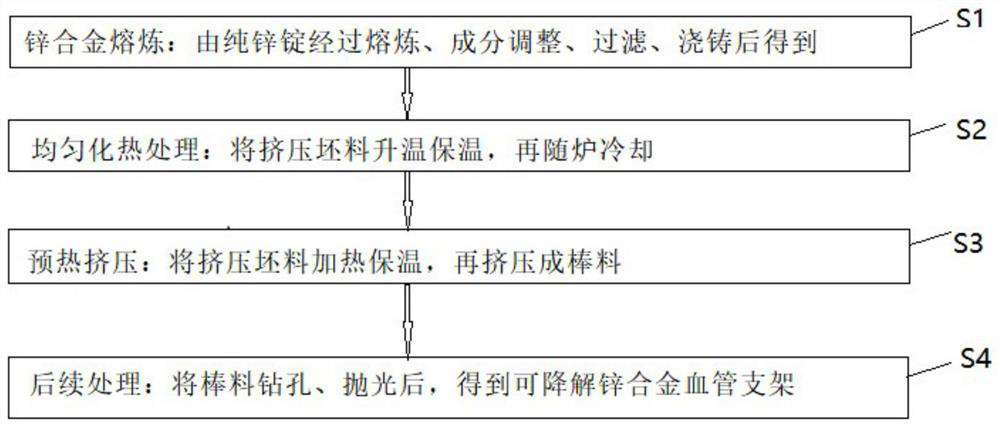

[0026] The invention provides a method for preparing a degradable vascular stent made of a zinc-based alloy material, comprising the following steps:

[0027] S1. Zinc alloy smelting: obtained from pure zinc ingots after smelting, composition adjustment, filtration, and casting;

[0028] Specifically, during the smelting process, all contact surfaces of the melt are made of high-purity graphite or boron nitride, and the melt is filtered through a graphite filter. This filtering process effectively absorbs and intercepts non-metallic impurities in the melt, ensuring that the filtered melt Quality, the zinc alloy melt is molded after being cast by a mold, and finally made into an extrusion billet with a diameter of 45-50mm and a height of 110-150mm;

[0029] The zinc alloy smelting process is as follows: put the zinc alloy into the vacuum melting furnace, heat the metal to 550-660°C and keep it warm, add Cu, Mg, Li and other metal elements after reaching the temperature point, a...

Embodiment 1

[0038] A method for preparing a degradable zinc-based vascular stent alloy material, wherein the zinc alloy ratio is controlled by 3% for Cu and 0.015% for Mg, and high-purity graphite and boron nitride materials are used in the smelting process and the liquid contact surface . The zinc alloy raw materials are: pure zinc, whose purity is greater than 99.995%; pure copper, whose purity is greater than 99.995%; zinc-magnesium master alloy, whose magnesium content is 2%.

[0039] Melting process: Put the zinc alloy into the melting furnace, heat the metal to 580°C and keep it warm, add Cu, Mg, Li and other metal elements after reaching the temperature point, and stir evenly, reheat the melt to 580°C, and let it stand for 0.5h , and then filtered and cast into an ingot to make an extrusion billet with a diameter of 50mm

[0040] Homogenization heat treatment: the temperature of the extrusion billet is controlled at 300°C, the holding time is controlled at 48 hours, and the extrus...

Embodiment 2

[0045]A preparation method of a degradable zinc-based vascular stent alloy material, the proportion of the zinc alloy is controlled by 1% for Cu, 0.05% for Mg, and the rest is Zn content, and high-purity graphite is used in the melting process and the liquid contact surface and boron nitride materials. The zinc alloy raw materials are: pure zinc, whose purity is greater than 99.995%; pure copper, whose purity is greater than 99.995%; zinc-magnesium master alloy, whose magnesium content is 2%.

[0046] Melting process: Put the zinc alloy into the melting furnace, heat the metal to 590°C and keep it warm, add Cu, Mg, Li and other metal elements after reaching the temperature point, and stir evenly, reheat the melt to 590°C, and let it stand for 1h. Then filtered and cast into ingots to make extrusion billets with a diameter of 50mm

[0047] Homogenization heat treatment: the temperature of the extrusion billet is controlled at 300°C, the holding time is controlled at 48 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com