Anti-aging and anti-cracking polycrystalline solar cell backboard

A solar cell, anti-aging technology, applied in circuits, electronic equipment, photovoltaic power generation, etc., can solve the problems of general mechanical performance strength and stability, affecting the service life of solar cell back sheets, and unable to meet the requirements of low water vapor transmission rate. , to achieve the effect of reducing water vapor transmission rate, good water vapor barrier, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

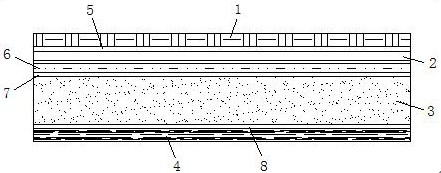

[0021] see figure 1 , the present invention provides the following technical solutions: an anti-aging and anti-cracking polycrystalline solar battery back sheet, comprising an outer weather-resistant protective layer 1, a barrier layer 2, a structural reinforcement layer 3 and a laminated adhesive layer 4, wherein the outer layer is weather-resistant The protective layer 1 and the barrier layer 2 are bonded and fixed by the first adhesive layer 5, the inner surface of the barrier layer 2 is provided with an anti-crack coating 6, and the anti-crack coating 6 is a PET / carbon black / carbon fiber composite coating , the anti-crack coating 6 is bonded and fixed to the structural reinforcement layer 3 through the second adhesive layer 7 , and the structural reinforcement layer 3 is bonded and fixed to the lamination adhesive layer 4 through the third adhesive layer 8 .

[0022] Specifically, the outer weather-resistant protective layer 1 is a fluorine material layer, and the fluorine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com