High-resolution low-temperature flexible strain resistance switch and preparation method thereof

A low-temperature flexibility and strain resistance technology, applied in electrical components and other directions, can solve problems such as bottlenecks in highly flexible films, and achieve the effects of large magnetoresistance effect, high ferromagnetic Curie temperature, and high orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

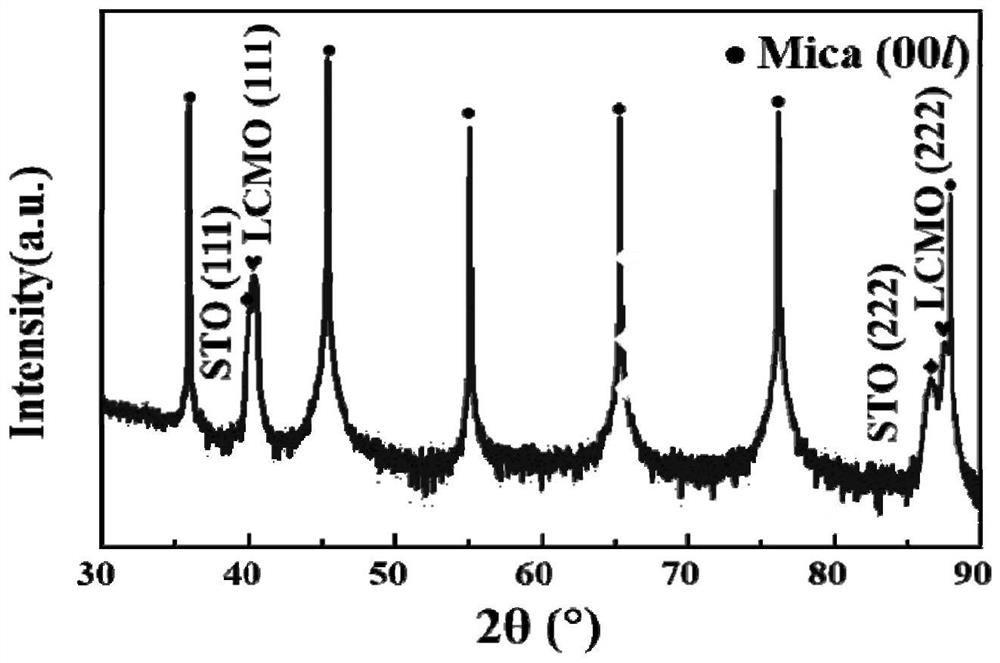

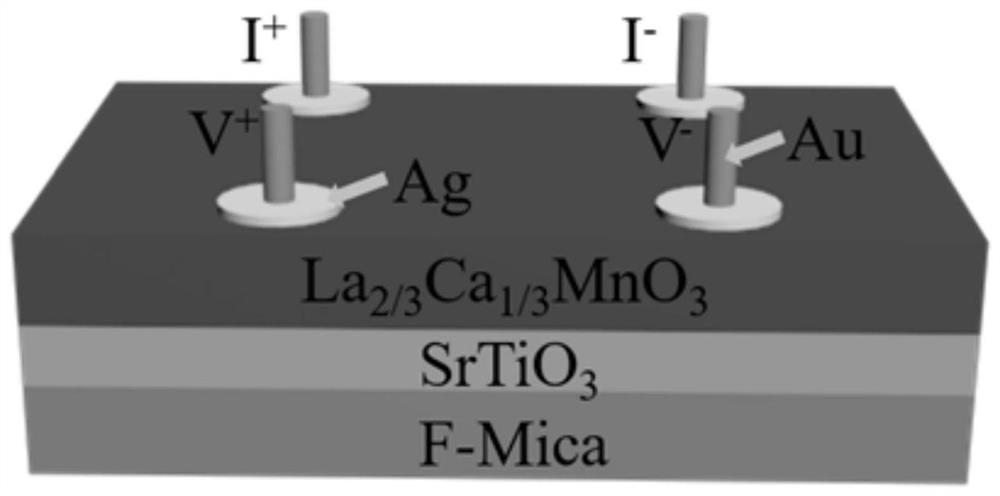

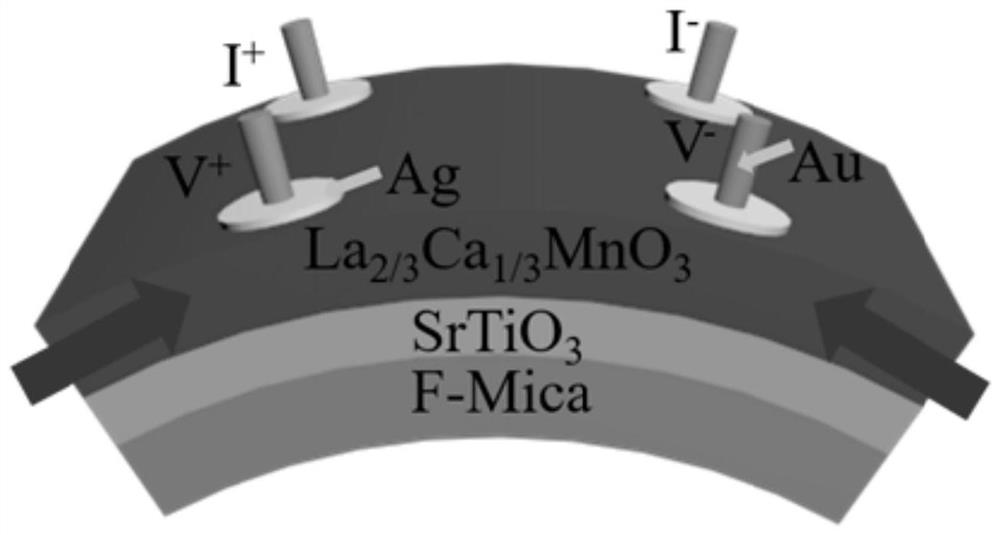

[0042] The high-resolution low-temperature flexible strain gauge switch of this embodiment is a heteroepitaxial oxide film with a composite structure of LCMO / STO / F-Mica, and its preparation method is as follows:

[0043] (1) First, according to the chemical formula La 2 / 3 Ca 1 / 3 MnO 3 and SrTiO 3 , respectively weigh appropriate amount of high-purity 4-5N grade LaO powder, CaO powder, SrO powder, TiO powder 2 Powder and MnO 2 Powder, the mixture of the above high-purity powder according to La 2 / 3 Ca 1 / 3 MnO 3 and SrTiO 3 Proportion mixed for ball milling, pre-sintering, granulation, molding and sintering and other processes, using the traditional solid-phase ceramic preparation process to prepare La 2 / 3 Ca 1 / 3 MnO 3 Ceramic target and SrTiO 3 Ceramic target. In the process of preparing the ceramic target, the sintering temperature is lower than the phase formation temperature of the system by 100-200°C.

[0044] (2) The prepared ceramic target material is first gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com