Production method for oil/fat composition rich in palmitic acid at position 2

A technology of oil composition and manufacturing method, applied in the direction of edible oil/fat, food science, fatty acid esterification, etc., capable of solving problems such as nutritional differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] After adding 0.15% by weight of sodium methoxide to palm stearin (iodine value 14.2), and performing a random transesterification reaction at 80° C. for 30 minutes, it was washed with water in accordance with a conventional method to obtain a palm stearin random transesterified oil. The 2-position palmitic acid content of this oil was 80 weight%, and the acid value was 0.24. Mix 20 parts by weight of this oil as a raw material oil, and 80 parts by weight of ethyl oleate (the content of oleic acid in the constituent fatty acids is 84% by weight, and the acid value is 8.8) as a raw material fatty acid ester, etc., to obtain a raw material mixture. The cloud point of the raw material mixture is 26.0°C, which is acceptable. While maintaining this raw material mixture at 45° C., a transesterification reaction was carried out by passing through a fixed-bed reactor filled with 1.3-specific lipase. After the reaction, the obtained reaction liquid was separated into a triglyc...

Embodiment 2

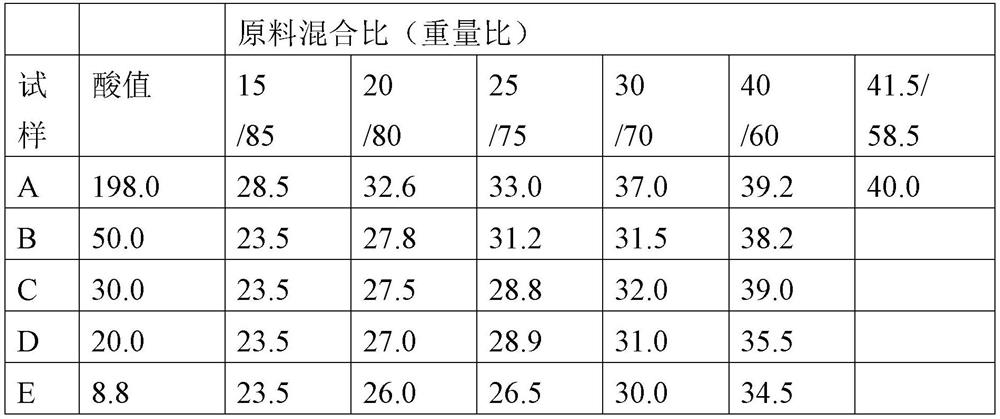

[0079] As a raw material fatty acid ester, etc., ethyl oleate (purity 80% by weight, acid value 8.8) was mixed with oleic acid (purity 80% by weight, acid value 198.0) to prepare a mixture with a specific acid value, and a test product with an acid value of 198.0 was obtained. Sample A (single product of oleic acid), sample B with an acid value of 50.0, sample C with an acid value of 30.0, sample D with an acid value of 20.0, and sample E with an acid value of 8.8.

[0080] Samples A to E of these raw material fatty acid esters and the like were randomly transesterified with the palm stearin oil obtained in Example 1 so that the raw material fat / raw material fatty acid esters were 15 / 85, 20 / 80, and 25 / 75, 30 / 70, 40 / 60, 41.5 / 58.5 to adjust the raw material mixture, and measure its cloud point. The results are shown in Table 1.

[0081] Cloud point (℃) of table 1 raw material mixture (iodine value of raw material oil and fat 14.2)

[0082]

[0083] The cloud point tends to...

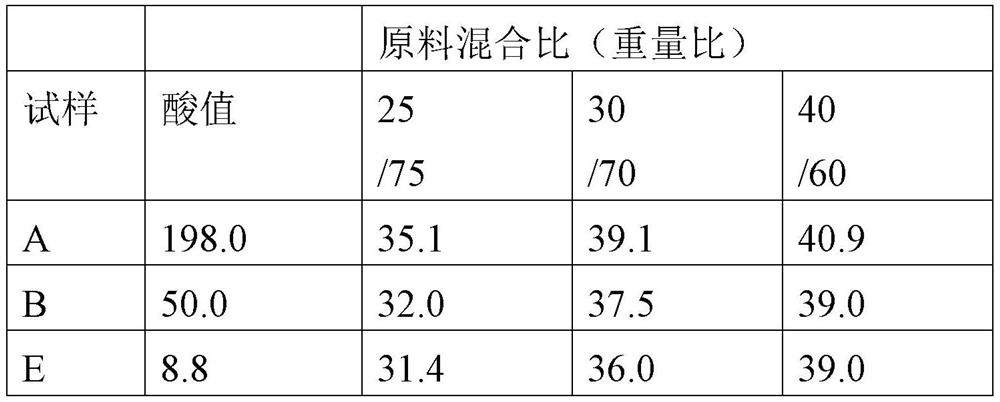

Embodiment 3

[0085] Except having used the palm stearin of iodine value 17.5, it carried out similarly to Example 1, obtained the palm stearin random transesterification oil, and used it as raw material fats and oils.

[0086] In addition, as the raw material fatty acid ester, etc., a sample A (oleic acid single product) with an acid value of 198.0 was used to prepare a raw material mixture such that the raw material fat / raw material fatty acid ester was 40 / 60, and the cloud point thereof was measured. As a result, it was 36.0°C, which was a pass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com