A kind of adsorbent capable of removing heavy metals in industrial wastewater and preparation method thereof

A technology for industrial wastewater and adsorbents, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc., can solve the problems of complex preparation process, high price, secondary pollution, etc., and achieve simple preparation process and cost. Low cost and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

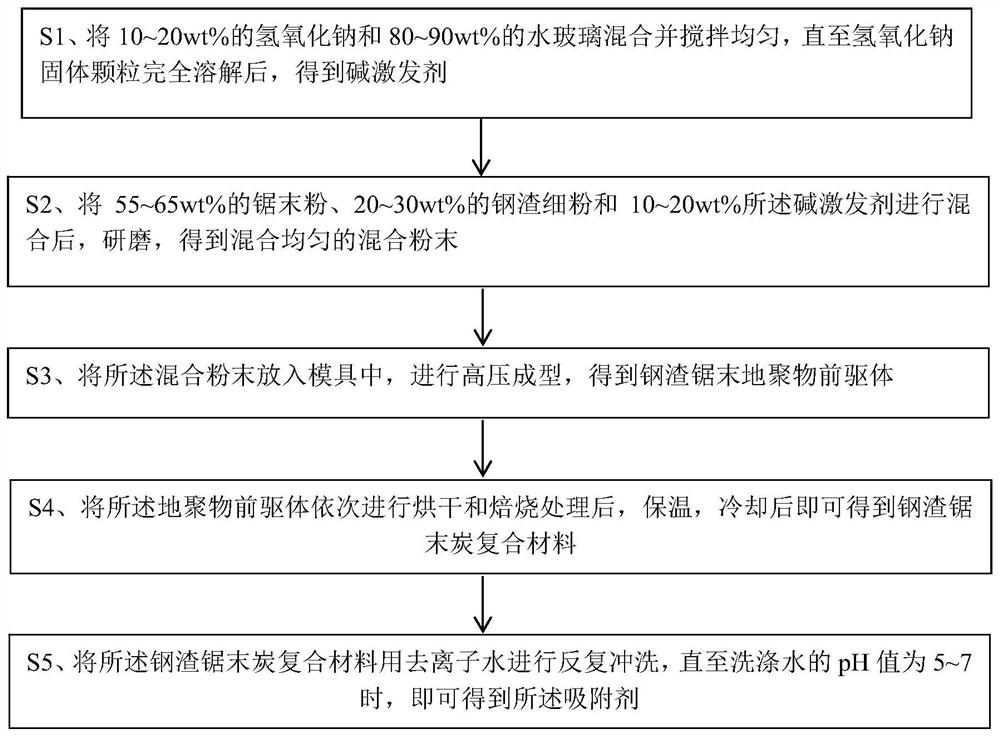

[0026] Please refer to figure 1 The invention provides a preparation method of an adsorbent capable of removing heavy metals in industrial wastewater. The specific steps are shown in the following examples.

[0027] Here, it should be noted that the raw materials and instruments used in the following implementations are all commercially available. Wherein, the sodium hydroxide is industrial grade sodium hydroxide, and the NaOH content in the sodium hydroxide is ≥99.0wt%; the particle size of the steel slag fine powder is less than or equal to 200 mesh; the particle size of the sawdust powder is 500 mesh to 200 mesh , the wood content is greater than or equal to 85wt%; the water glass is industrial grade water glass, and its modulus is 2.0-3.5.

Embodiment 1

[0029] A preparation method of an adsorbent capable of removing heavy metals in industrial wastewater, which mainly comprises the following steps:

[0030] S1, mix and stir 10wt% of sodium hydroxide and 90wt% of water glass until the sodium hydroxide solid particles are completely dissolved to obtain an alkali activator; wherein, the modulus of the water glass is 2.2;

[0031] S2, after mixing 58wt% of sawdust powder, 28wt% of steel slag fine powder and 14wt% of the alkali activator, grind in a grinder for 0.5-1 hour to obtain a uniformly mixed mixed powder;

[0032] S3. Put the mixed powder into a mold, and keep it for 1-3 min under a pressure of 110 MPa to obtain a slag sawdust geopolymer precursor;

[0033] S4. Drying the geopolymer precursor in an oven at 50-65°C for 8-10h, then calcining under nitrogen protection at a temperature of 600-750°C, keeping the temperature for 1-2.5h, and cooling to obtain steel slag Sawdust carbon composite material;

[0034] S5. Repeatedly ...

Embodiment 2

[0036] A preparation method of an adsorbent capable of removing heavy metals in industrial wastewater, which mainly comprises the following steps:

[0037] S1. Mix and stir 15wt% of sodium hydroxide and 85wt% of water glass until the sodium hydroxide solid particles are completely dissolved to obtain an alkali activator; wherein, the modulus of the water glass is 2.8;

[0038] S2, after mixing 60wt% of sawdust powder, 25wt% of steel slag fine powder and 15wt% of the alkali activator, grind in a grinder for 0.5 to 1 hour to obtain a uniformly mixed mixed powder;

[0039] S3. Put the mixed powder into a mold, and keep it for 1-3 min under a pressure of 130 MPa to obtain a slag sawdust geopolymer precursor;

[0040] S4. The geopolymer precursor is dried in an oven at 60-75°C for 9-11 hours, then calcined at a temperature of 700-800°C under nitrogen protection, kept for 1-2.5 hours, and cooled to obtain steel slag Sawdust carbon composite material;

[0041] S5. Repeatedly washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com