Preparation method of silver powder with low heat shrinkage rate

A technology of shrinkage and silver powder, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as inability to apply miniaturized and high-reliability circuits well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

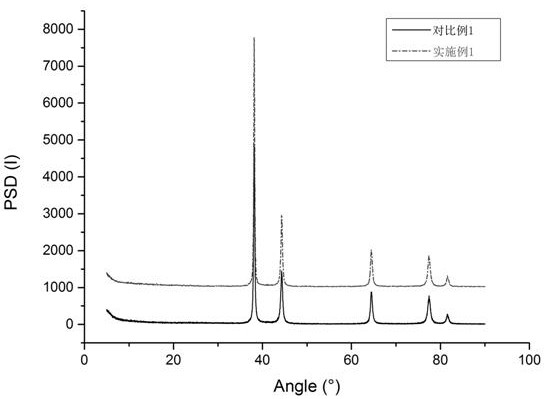

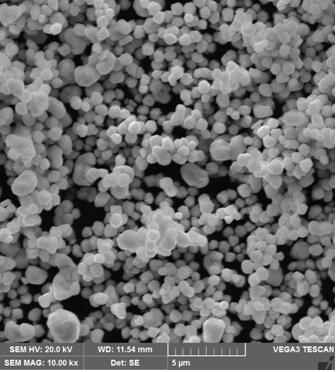

Embodiment 1

[0048] Step 1: Dissolve 40kg of high-purity silver nitrate crystals with 80L of deionized water in a temperature-controllable dissolving tank to prepare a 500g / L silver nitrate aqueous solution, and turn on the heating device to stabilize the temperature of the silver nitrate aqueous solution at 50°C; Dissolve 24kg of ascorbic acid crystals in 160L of deionized water in a temperature-controllable dissolving tank, adjust the pH value of the solution with sodium hydroxide, prepare a reducing agent solution with pH=3, and turn on the heating device to stabilize the temperature of the reducing agent solution at 50°C Add 440L deionized water in the reactor, turn on the stirring motor and set the rotating speed as 100r / min, open the heating device, make the temperature of the deionized water stable at 50°C, then add 1.25kg gum arabic in the reactor, after stirring The gum arabic was fully dissolved to make an aqueous dispersant solution; the speed of the silver nitrate aqueous soluti...

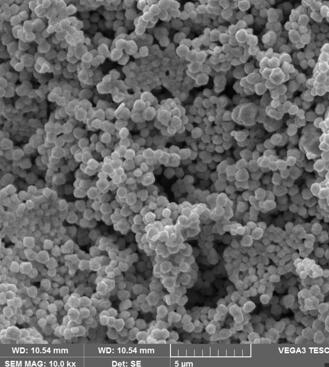

Embodiment 2

[0053] Step 1: Dissolve 25kg of high-purity silver nitrate crystals in 80L of deionized water in a temperature-controllable dissolving tank to prepare a 312.5g / L silver nitrate aqueous solution, and turn on the heating device to stabilize the temperature of the silver nitrate aqueous solution at 25°C; Dissolve 20kg of hydroquinone crystals with 160L of deionized water in a temperature-controllable dissolving tank to prepare a reducing agent solution with pH=6, and turn on the heating device to stabilize the temperature of the reducing agent solution at 25°C; Add 440L of deionized water, turn on the stirring motor and set the rotation speed to 300r / min, turn on the heating device to stabilize the temperature of the deionized water at 25°C, and then add 0.8kg of polyethylene glycol with a molecular weight of 1000 to the reaction kettle. The polyethylene glycol is fully dissolved to make a dispersant aqueous solution; the silver nitrate aqueous solution feeding peristaltic pump sp...

Embodiment 3

[0058] Step 1: Dissolve 30kg of high-purity silver nitrate crystals with 50L of deionized water in a temperature-controllable dissolving tank to prepare a 600g / L silver nitrate aqueous solution, and turn on the heating device to stabilize the temperature of the silver nitrate aqueous solution at 60°C; Dissolve 8kg of sodium hypophosphite crystals with 55L of deionized water in a temperature-controllable dissolving tank, adjust the pH value of the solution with sodium hydroxide, prepare a reducing agent solution with pH=8, and turn on the heating device to stabilize the temperature of the reducing agent solution At 60°C; add 580L of deionized water to the reactor, turn on the stirring motor and set the rotation speed to 150r / min, turn on the heating device to stabilize the temperature of the deionized water at 60°C, and then add 1.5kg of number-average molecular weight to the reactor The polyacrylic acid is 2000, under the action of stirring, the polyacrylic acid is fully dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com