Multiple layer system, method of manufacture and saw device formed on the multiple layer system

A layer system and device technology, applied in the field of multi-layer systems, manufacturing and SAW devices formed on multi-layer systems, can solve problems such as impossible effective coupling coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

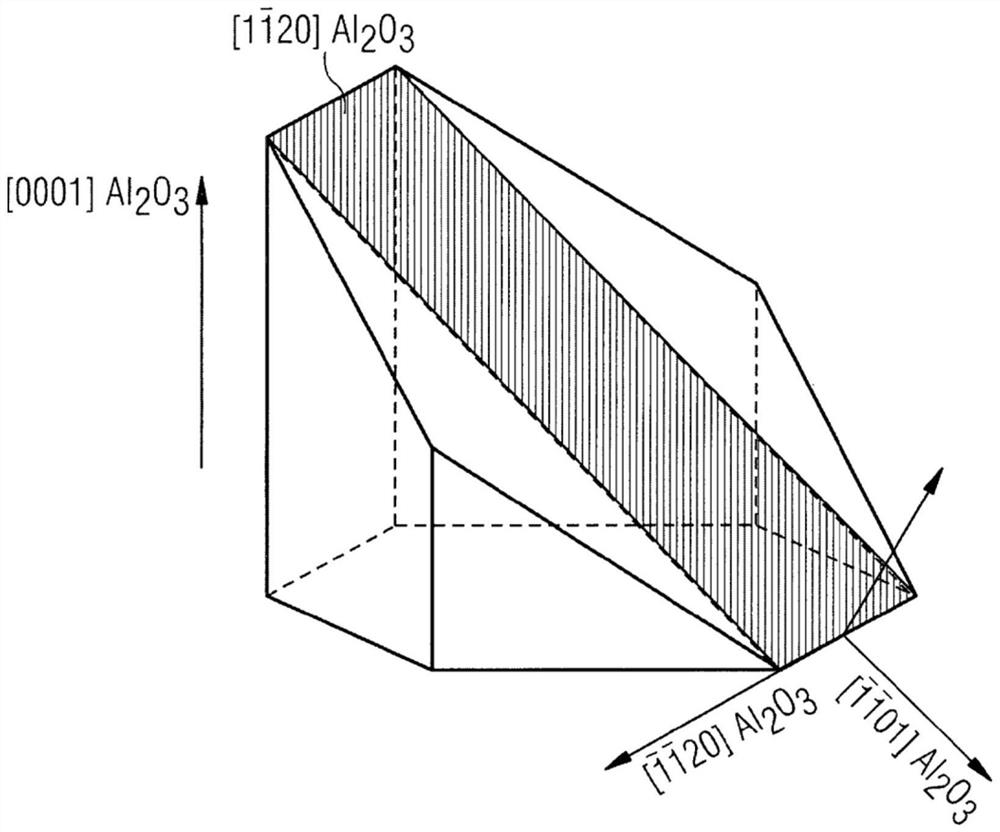

[0037] figure 1 The location of the R-plane within the sapphire crystal is shown schematically.

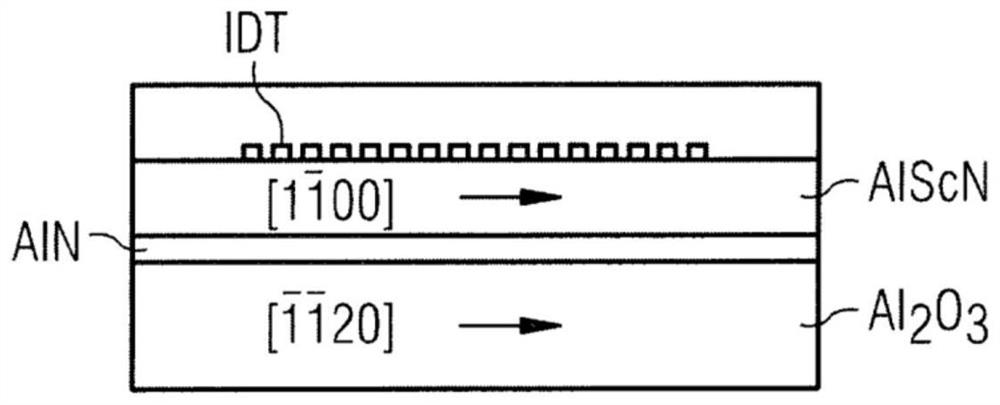

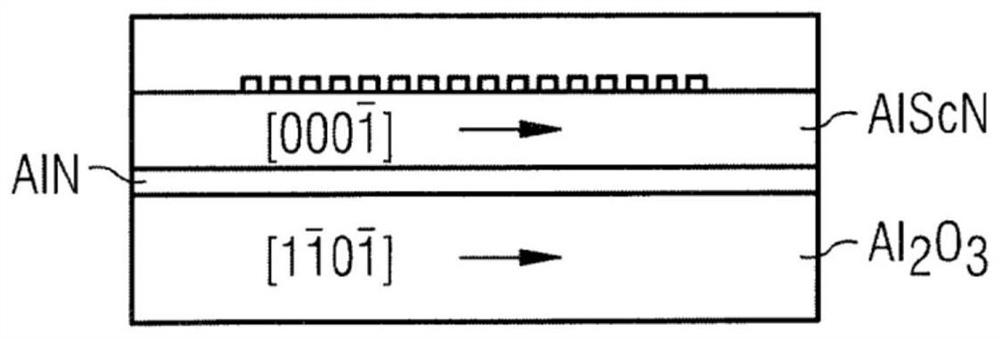

[0038] An AlScN layer with a Sc content of 40 mol% can be epitaxially grown directly onto this R-plane sapphire wafer. In this case, the [11-20] direction of the AlScN layer is perpendicular to the substrate surface (x-cut AlScN). According to an advantageous embodiment, a seed layer system, eg made of pure and undoped AlN, can be grown on the sapphire substrate as an underlayer. This AlN layer can support epitaxial growth. The thickness of the seed layer can be as thin as 30 nm, but can be adjusted as needed.

[0039] For epitaxial growth of AlScN layer on the seed layer, the deposition technique is selected from metal organic CVD (MOCVD), plasma enhanced CVD (PECVD), molecular beam epitaxy (MBE), atomic layer deposition (ALD), sol-gel Deposition, high temperature sputtering and pulsed laser deposition of PLD.

[0040] Furthermore, due to the fact that the speed of sound wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com