Degradable seedling raising pot and raw material composition and preparation method thereof

A technology of raw material composition and seedling pot, which is applied in the directions of botanical equipment and method, fertilizer mixture, organic fertilizer, etc., can solve the problems such as the ineffective utilization of bio-based substances such as citrus, high preparation cost of seedling pot, complicated treatment process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this example, the types and amounts of each component in the raw material composition of the degradable seedling pot are shown in Table 1. Add the raw material composition of the degradable seedling pot into the mixer and mix evenly to obtain the primary mixture. The mixing time is 30 minutes, and the rotation speed of the mixer is 200rpm; Press down for 10 minutes to form a degradable seedling pot with small holes on the surface.

[0042] Among them, the moisture content of citrus peel residue is 3%; the content of organic matter in peat is 45%, the specific gravity is 0.85, and the pH is 5.8; the particle size of humus soil is 1200 mesh; the moisture content of humus soil is 8%; The particle size of lactic acid is 100 mesh; the number average molecular weight of polylactic acid is 8000.

[0043] Table 1

[0044] components Dosage (parts) Citrus zest 20 Peat 40 humus 40 Perlite 2 polylactic acid 10 Attapulgite 3 ...

Embodiment 2

[0046] In this example, the types and amounts of each component in the raw material composition of the degradable seedling pot are shown in Table 2. Add the raw material composition of the degradable seedling pot into the mixer and mix evenly to obtain the primary mixture. The mixing time is 30 minutes, and the rotation speed of the mixer is 200rpm; Press down for 10 minutes to form a degradable seedling pot with small holes on the surface.

[0047] Among them, the moisture content of citrus peel residue is 3%; the content of organic matter in peat is 45%, the specific gravity is 0.85, and the pH is 5.8; the particle size of humus soil is 1200 mesh; the moisture content of humus soil is 8%; The particle size of lactic acid is 100 mesh; the number average molecular weight of polylactic acid is 8000.

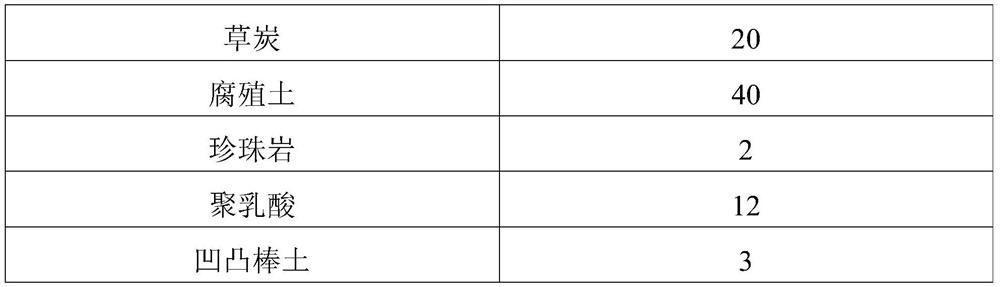

[0048] Table 2

[0049] components Dosage (parts) Citrus zest 20 Peat 40 humus 40 Perlite 2 polylactic acid 12 Attapulgite 3 ...

Embodiment 3

[0051]In this example, the types and amounts of each component in the raw material composition of the degradable seedling pot are shown in Table 3. Add the raw material composition of the degradable seedling pot into the mixer and mix evenly to obtain the primary mixture. The mixing time is 30 minutes, and the rotation speed of the mixer is 150rpm; Press down for 10 minutes to form a degradable seedling pot with small holes on the surface.

[0052] Among them, the moisture content of citrus peel residue is 3%; the content of organic matter in peat is 45%, the specific gravity is 0.85, and the pH is 5.8; the particle size of humus soil is 1200 mesh; the moisture content of humus soil is 8%; The particle size of lactic acid is 100 mesh; the number average molecular weight of polylactic acid is 8000.

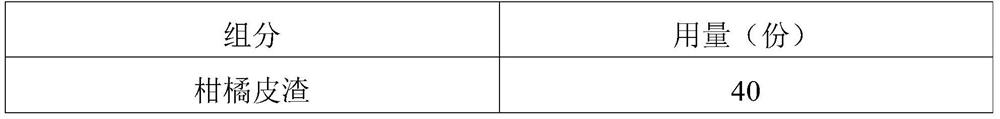

[0053] table 3

[0054] components Dosage (parts) Citrus zest 30 Peat 30 humus 40 Perlite 2 polylactic acid 12 Attapulgite 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com