Preparation method and application of LGG fermentation product containing immunomodulatory peptide functional components

A technology of immune regulation and fermentation products, applied in the direction of microorganism-based methods, biochemical equipment and methods, functions of food ingredients, etc., can solve problems that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

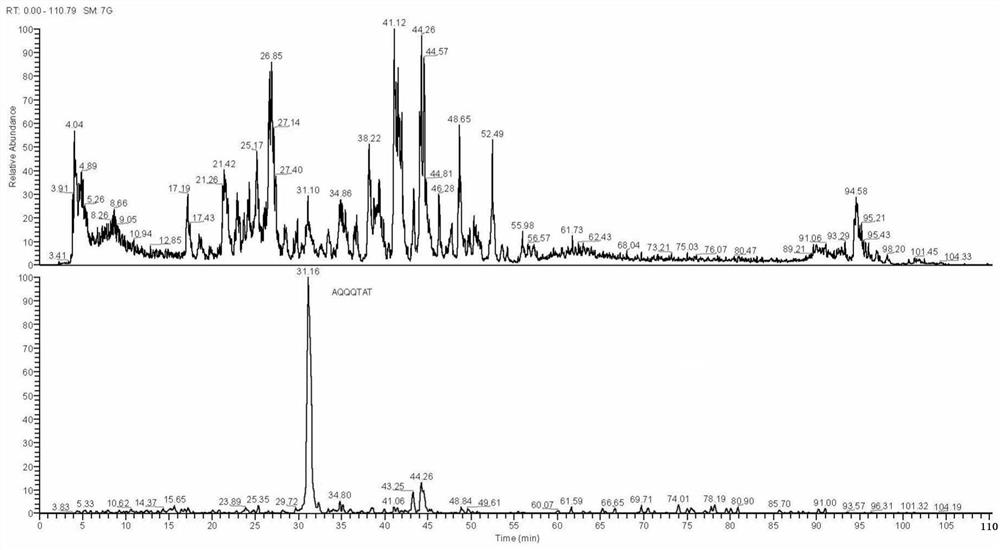

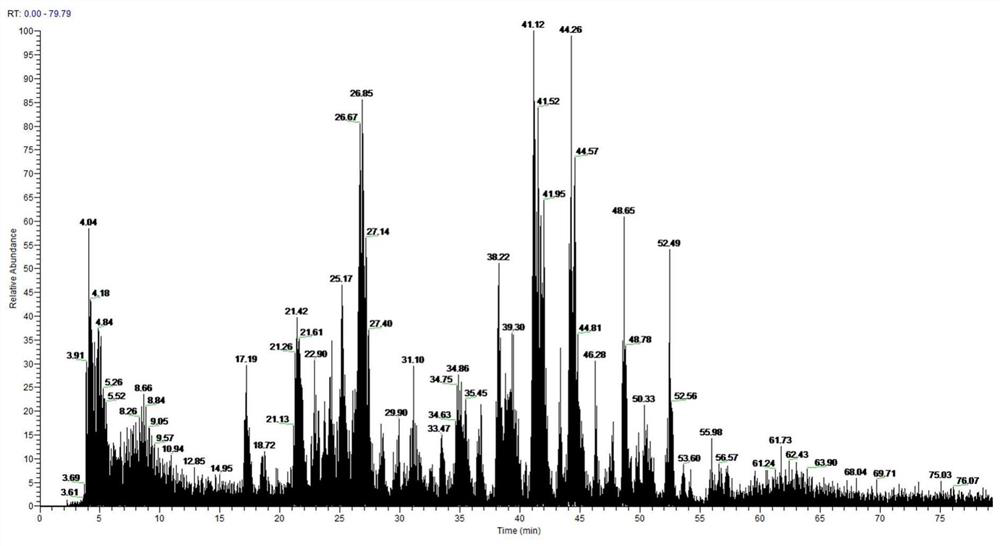

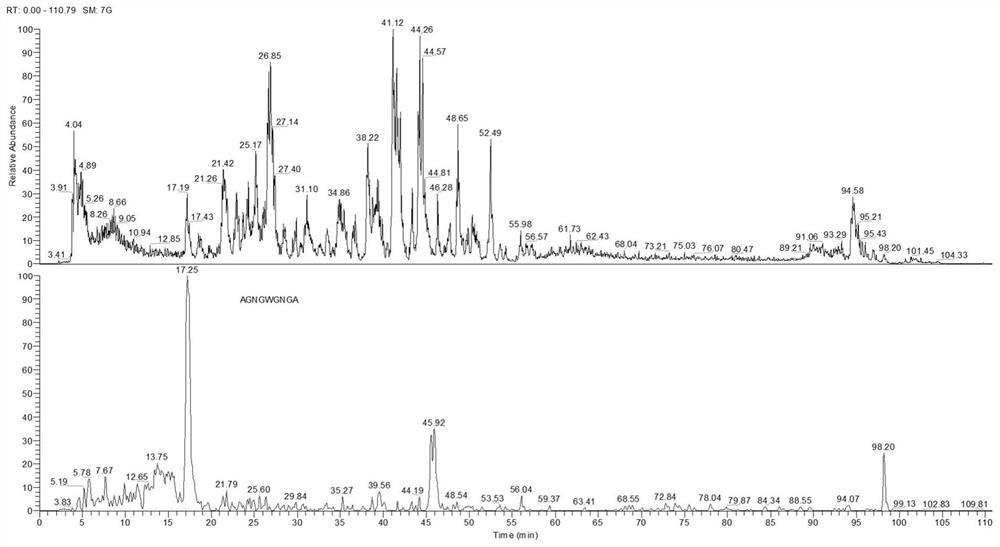

Image

Examples

preparation example Construction

[0040] According to one embodiment of the present invention, a preparation method and application thereof of LGG fermentation products containing functional components such as immunomodulatory peptides are provided, the method comprising:

[0041] The pretreatment step of the fermentation substrate is to pretreat the fermentation substrate. The substrate used is animal milk such as milk or goat milk or animal protein concentrates such as milk powder and milk protein, and is stirred and dissolved at 50-60°C for 20-30 Minutes to fully dissolve the hydration;

[0042]The step of adding a carbon source, adding a carbon source to the raw material mixture, stirring and dissolving at 50-60°C for 20-30 minutes, wherein the carbon source is selected from glucose, fructose, galactose, mannose, ribose, Rhamnose, maltose, arabinose, sorbose, cellobiose, trehalose, tagatose, fucose or a combination thereof, the carbon source is added in an amount of 0.1-10% relative to the mass percentage ...

Embodiment 1

[0051] Step a, using fresh milk with a milk protein content of 3.1 and a total solid content of 12% as a fermentation substrate for pretreatment, stirring and dissolving at 50-60°C for 25 minutes, fully dissolving and hydrating, and forming a raw material mixture;

[0052] Step b, adding glucose to the raw material mixture in an amount of 0.5% by mass of the raw material mixture, stirring and dissolving at 50-60°C for 25 minutes;

[0053] Step c, adding yeast extract and wort juice to the raw material mixed solution as nutritional molecules, the amount of yeast extract added is 0.03% of the mass percentage of the raw material mixed solution, and the wort is 0.05%;

[0054] Step d, homogenizing and sterilizing the raw material mixture added with the carbon source and nutritional factors;

[0055] Step e, cooling the homogenized and sterilized raw material mixture to 46°C, inoculating Lactobacillus rhamnosus LGG for fermentation under aseptic conditions, the amount added is 5*10...

Embodiment 2

[0059] Step a, using 12% whole milk powder and 0.5% WPC80 as a fermentation substrate, performing pretreatment, stirring and dissolving at 50-60°C for 30 minutes, fully dissolving and hydrating, and forming a raw material mixture;

[0060] Step b, adding maltose to the raw material mixture in an amount of 1% of the mass percentage of the raw material mixture, stirring and dissolving at 50-60°C for 25 minutes;

[0061] Step c, adding wort and corn juice to the raw material mixture as nutritional molecules, the amount of wort added is 0.05% of the mass percentage of the raw material mixture, and the amount of corn juice is 0.05%;

[0062] Step d, homogenizing and sterilizing the raw material mixture added with the carbon source and nutritional factors;

[0063] Step e, cooling the homogenized and sterilized raw material mixture to 38°C, inoculating Lactobacillus rhamnosus LGG for fermentation under aseptic conditions, the amount added is 1.2*10 6 cfu / ml(g);

[0064] Step f, cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com