Anti-aging face cream containing ampelopsis grossedentata and preparation method of anti-aging face cream

A technology for displaying Snake Grape and Snake Grape leaves, which is applied to medical preparations containing active ingredients, skin care preparations, and pharmaceutical formulas, and can solve problems such as easy yellowing and poor efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An anti-aging face cream containing snake grape, comprising the following steps:

[0030] (1) Weighing the extract of grape leaves and 3% water according to the formula ratio, mixing evenly to form an inner water phase;

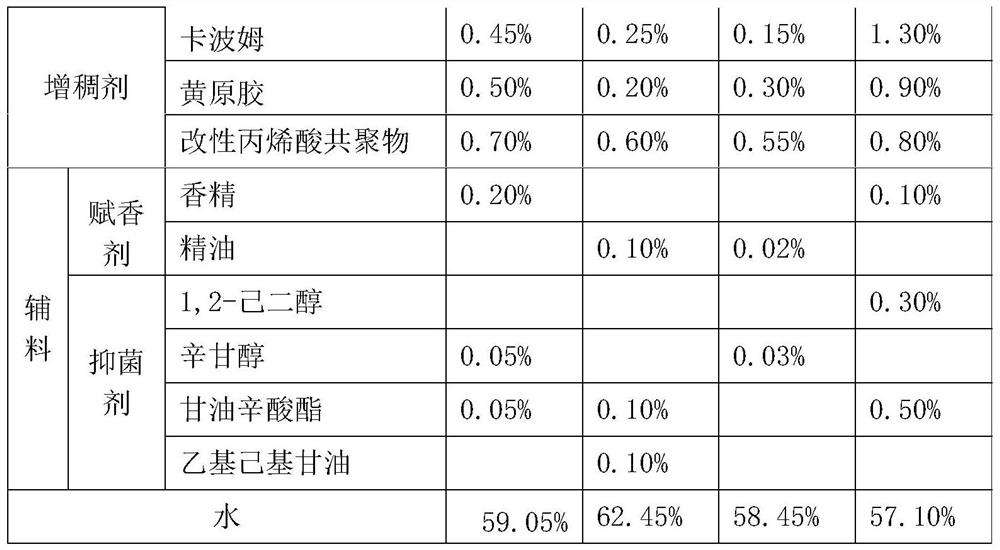

[0031] (2) Take the lipophilic emulsifier according to the formula ratio in Table 1, and mix uniformly to form the first oil phase;

[0032] (3) slowly adding the internal water phase in step (1) to the first oil phase in step (2) to form a water-in-oil W / O emulsion;

[0033] (4) Weigh the hydrophilic emulsifier and emollient according to the formula ratio, heat to 80-85°C and stir to dissolve to form the second oil phase;

[0034] (5) Weigh the remaining water, humectant, carbomer, and xanthan gum according to the formula ratio, heat to 80-85°C and stir to dissolve to obtain the outer water phase;

[0035] (6) Pump the second oil phase in step (4) into the outer water phase in step (5), stir homogeneously for 5 minutes, set the temperature to 80°C, ...

Embodiment 2

[0037] (1) Take the extract from the leaves of Snake-toothed grape and 3% water according to the formula ratio, and mix them evenly to form an inner water phase;

[0038] (2) Take the lipophilic emulsifier by weighing the formula ratio in Table 1, and mix uniformly to form the first oil phase;

[0039] (3) slowly adding the internal water phase in step (1) to the first oil phase in step (2) to form a water-in-oil W / O emulsion;

[0040] (4) Weigh the hydrophilic emulsifier and emollient according to the formula ratio, heat to 85°C and stir to dissolve to form the second oil phase;

[0041] (5) Weigh the remaining water, humectant, carbomer, and xanthan gum according to the formula ratio, heat to 80-85°C and stir to dissolve to obtain the outer water phase;

[0042] (6) Pump the second oil phase in step (4) into the outer water phase in step (5), stir homogeneously for 10 minutes, set the temperature to 85°C, add modified acrylic acid copolymer (mixture) and stir homogeneously to...

Embodiment 3

[0044] (1) Weighing the extract of grape leaves and 3% water according to the formula ratio, mixing evenly to form an inner water phase;

[0045] (2) Take the lipophilic emulsifier according to the formula ratio in Table 1, and mix uniformly to form the first oil phase;

[0046] (3) slowly adding the internal water phase in step (1) to the first oil phase in step (2) to form a water-in-oil W / O emulsion;

[0047] (4) Weigh the hydrophilic emulsifier and emollient according to the formula ratio, heat to 80°C and stir to dissolve to form the second oil phase;

[0048] (5) Weigh the remaining water, humectant, carbomer, and xanthan gum according to the formula ratio, heat to 80-85°C and stir to dissolve to obtain the outer water phase;

[0049] (6) Pump the second oil phase in step (4) into the outer water phase in step (5), stir homogeneously for 5 minutes, set the temperature to 80°C, add modified acrylic acid copolymer (mixture) and stir homogeneously to increase Thick, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com