Double-unit UV photocatalytic oxidation reaction device

A photocatalytic oxidation and reaction device technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as large size, difficult equipment disassembly, and photocatalysts that are not suitable for air purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

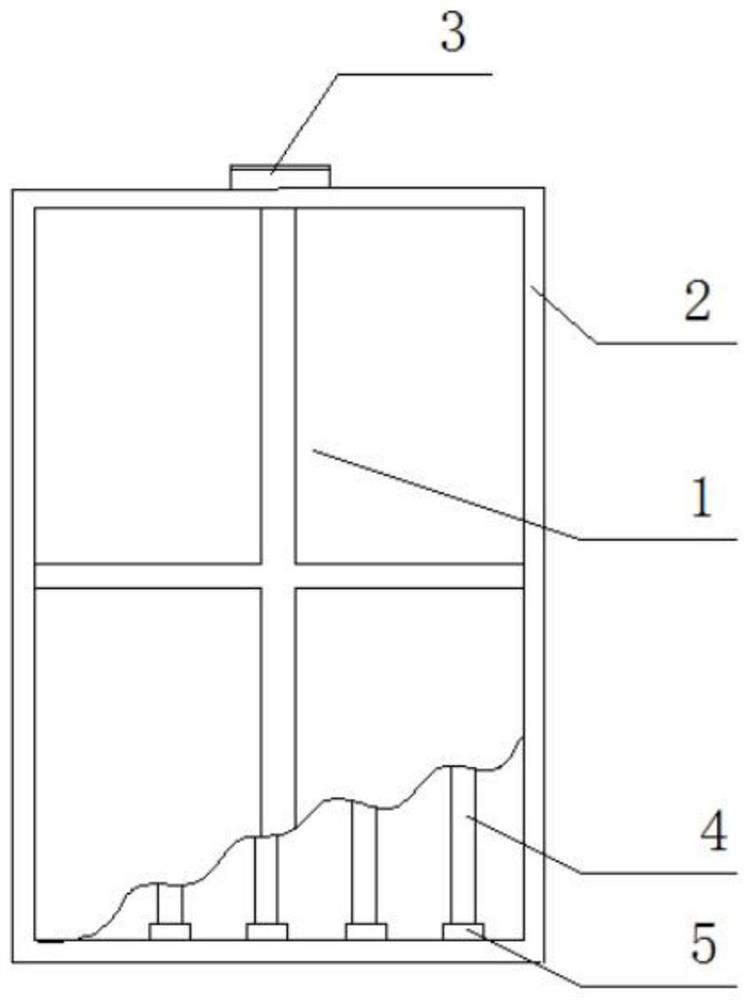

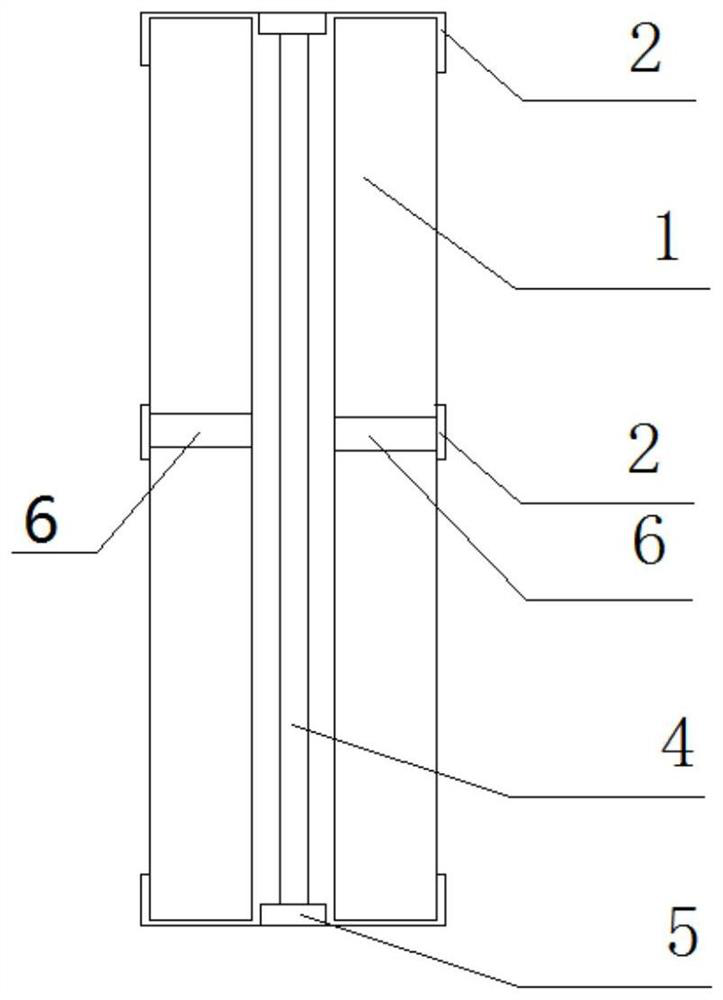

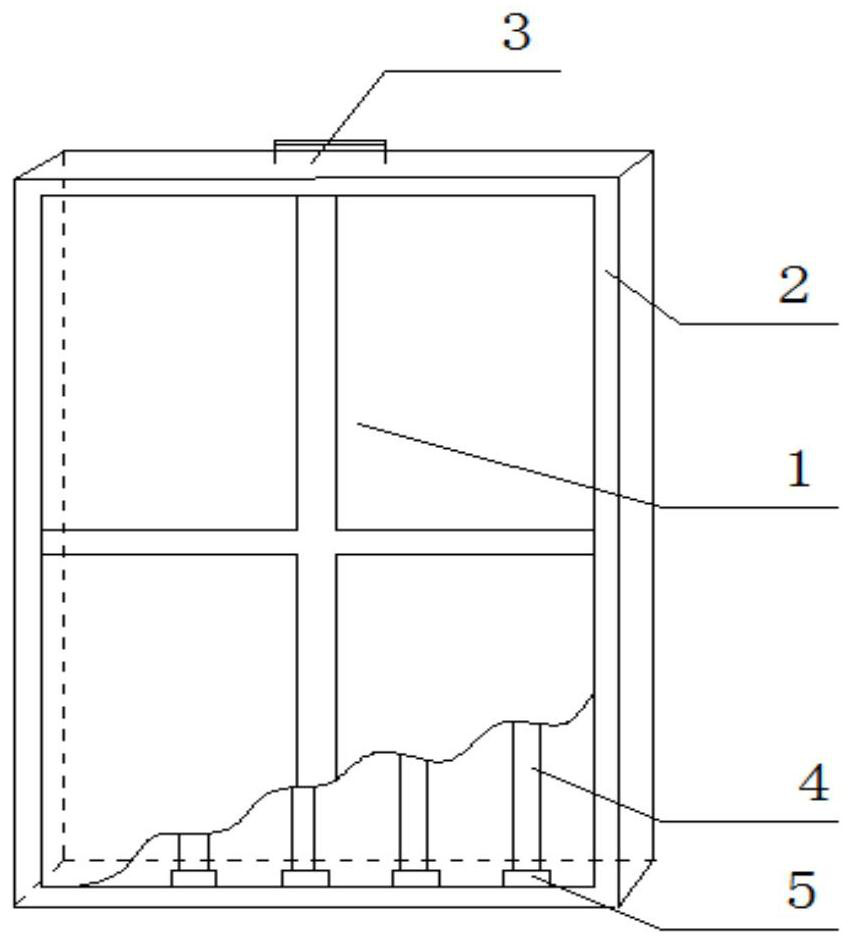

[0045] Attached below Figure 1 ~ Figure 4 , the present invention is further described:

[0046] A dual-unit UV photocatalytic oxidation reaction device, the dual-unit UV photocatalytic oxidation reaction device is composed of two photocatalytic unit reactors and ultraviolet lamp groups alternately stacked in parallel, each photocatalytic unit reactor includes an outer frame 2. Three-dimensional porous ceramic foam composite new composite immobilized photocatalyst 1, ultraviolet lamp group 4, lamp holder 5, the outer frame 2 is in the shape of "Tian", the outer frame 2 is a rectangular frame with a cross structure, the cross structure and the rectangular frame The space is filled with three-dimensional porous foam ceramic new composite immobilized photocatalyst 1, the number of outer frames 2 is two and parallel to each other, and an ultraviolet lamp group 4 is arranged between the two outer frames 2, and the ultraviolet lamp group 4 is several vertical For the vertically pl...

Embodiment 2

[0053] The preparation method of novel composite immobilized photocatalyst of the present invention comprises the following steps:

[0054] Step 1, preparation of titanium phosphate titanium dioxide sol aqueous solution

[0055] (1) Aqueous solution of titanium phosphate compound:

[0056] TiCl 4 Mix with absolute ethanol at a ratio of 1:15 by volume, stir evenly in the reactor, then add 10g of phosphoric acid solution, and fully mix evenly with hydrothermal reaction at 140°C to obtain 1-1.5wt% titanium phosphate compound in water.

[0057] (2) titanyl sulfate inorganic sol:

[0058] dissolving titanyl sulfate with a solid content of more than 90% in water, and performing a hydrothermal reaction at 500-600°C to obtain titanyl sulfate inorganic sol;

[0059] (3) Aqueous solution of composite titanium dioxide phosphate titanium dioxide sol:

[0060] (4) Mix the titanium phosphate compound aqueous solution and titanyl sulfate inorganic sol at a volume ratio of 10:4~6 and adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com