A method for manufacturing a multi-channel current sensor for new energy vehicles

A current sensor and new energy vehicle technology, applied to the components of electrical measuring instruments, only measuring current, measuring current/voltage, etc., can solve problems such as prolonging the production cycle, short circuiting of components, increasing connection materials, etc., to ensure The effect of yield and consistency, improvement of product compactness, and improvement of positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

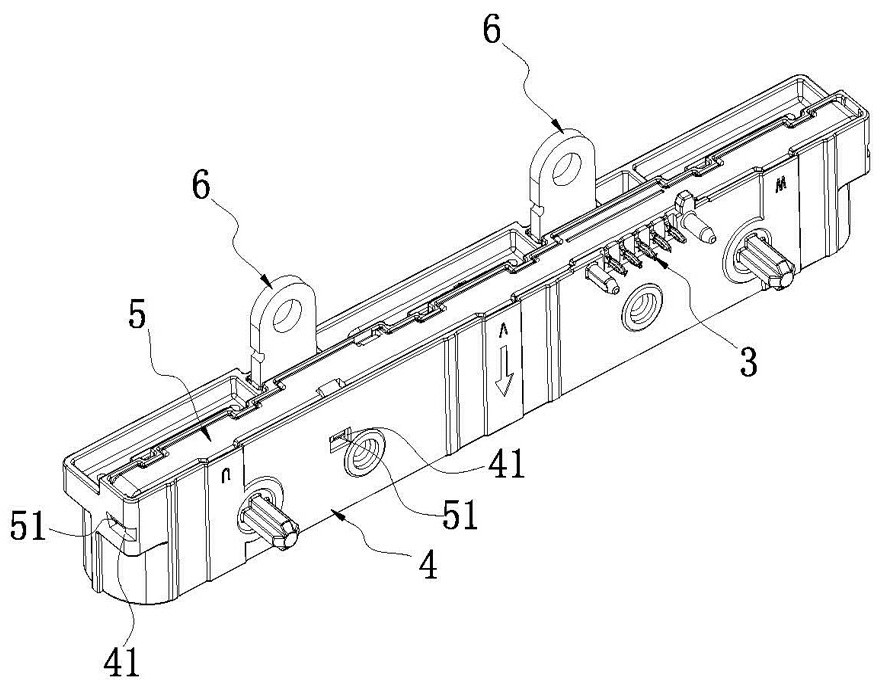

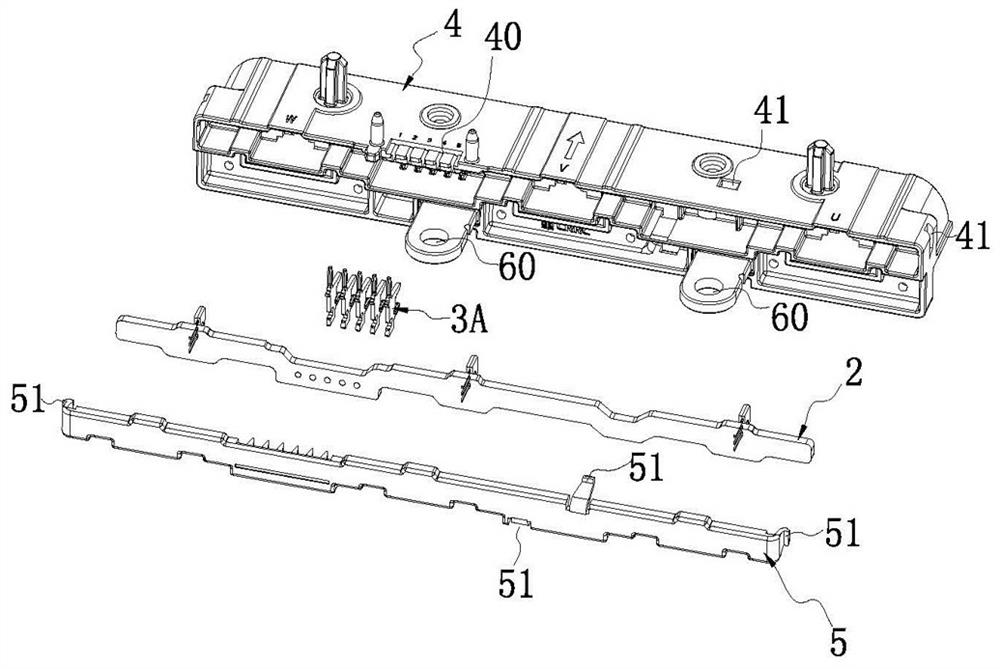

[0042] like Figure 2-Figure 4 As shown, a method for manufacturing a multi-channel current sensor for new energy vehicles, wherein the multi-channel current sensor includes an iron core 1, a circuit board 2, pins 3, a housing 4, a housing cover 5 and mounting feet 6 ; The iron core 1 and the mounting feet 6 are integrally injection-molded with the housing 4, the pins 3 and the circuit board 2 are press-fitted on the housing 4, and the housing cover 5 is also press-fitted on the housing 4, and the cover is provided on the insert Above the needle 3 and the circuit board 2 to ensure the stability of the overall structure of the product.

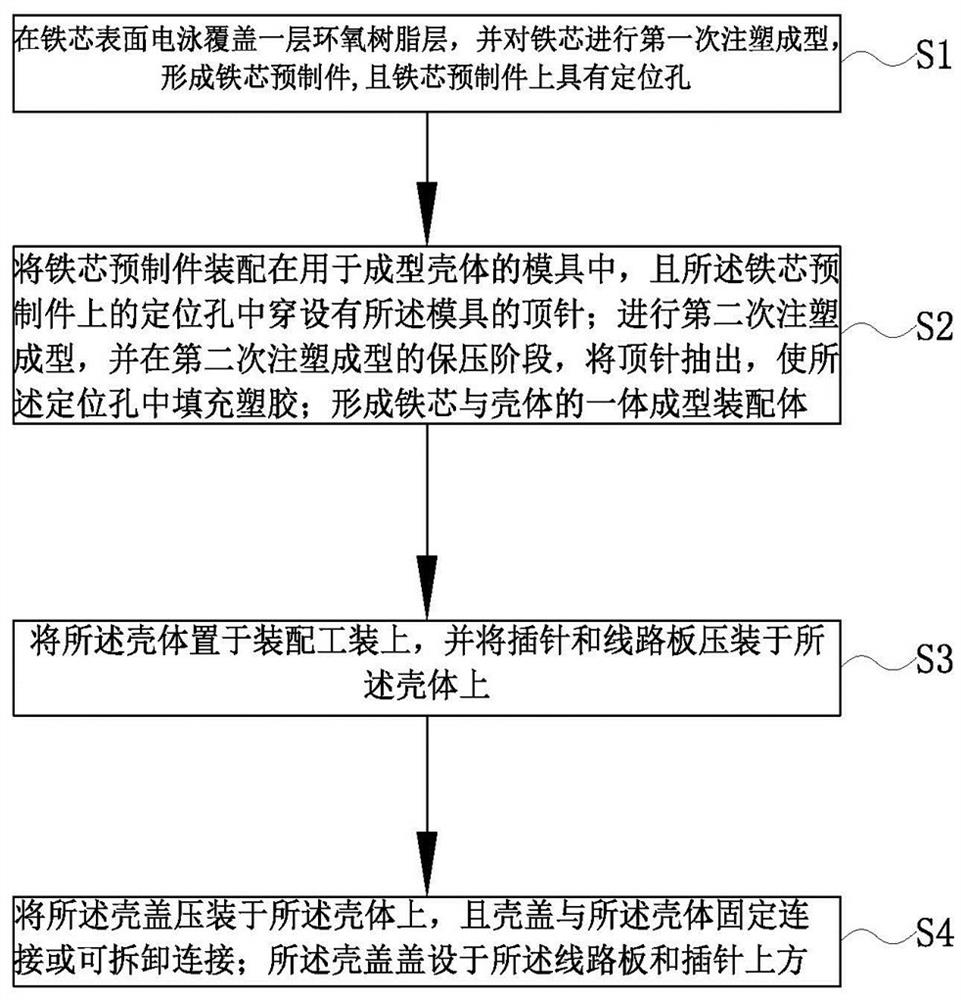

[0043] like figure 1 As shown, the manufacturing method of the multi-channel current sensor includes the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com