Synthetic method for GHK copper peptides

A synthesis method and copper peptide technology are applied in the field of GHK copper peptide synthesis in industrial mass production, which can solve the problems of unstable parameter requirements, uneconomical and environmental protection of GHK copper peptide products, and achieve high yield, low cost and controllable parameters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

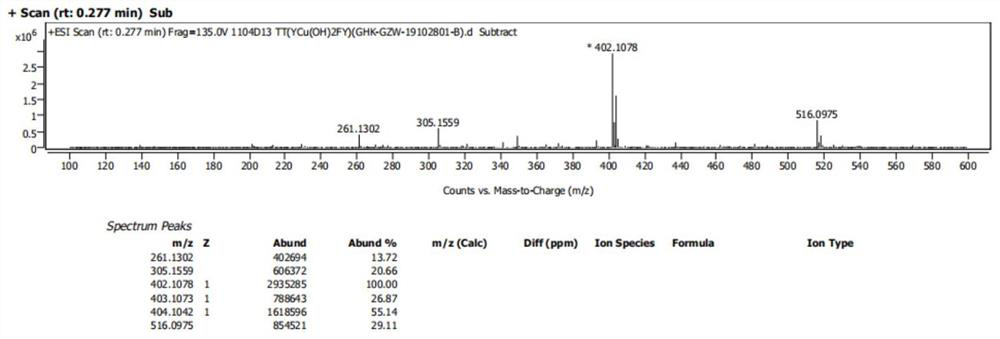

Embodiment 1

[0039] Dissolve 0.54g of copper acetate in 20ml of distilled water, add 1.02g of GHK tripeptide under stirring conditions, stir and react at room temperature (30°C) for 3 hours, filter and concentrate, then add 1ml of diethylamine, stir for 30min, add 90ml of ethanol precipitated solids, filtered, washed the filter cake with distilled water and then dissolved in 10ml of distilled water, added 0.13ml of glacial acetic acid, stirred and reacted for 1 hour and then concentrated and freeze-dried to obtain 0.905g of GHK copper peptide complex with a purity of 98%. The rate is 72%, the acetic acid content is 16.1%, and the copper content is 10.6%.

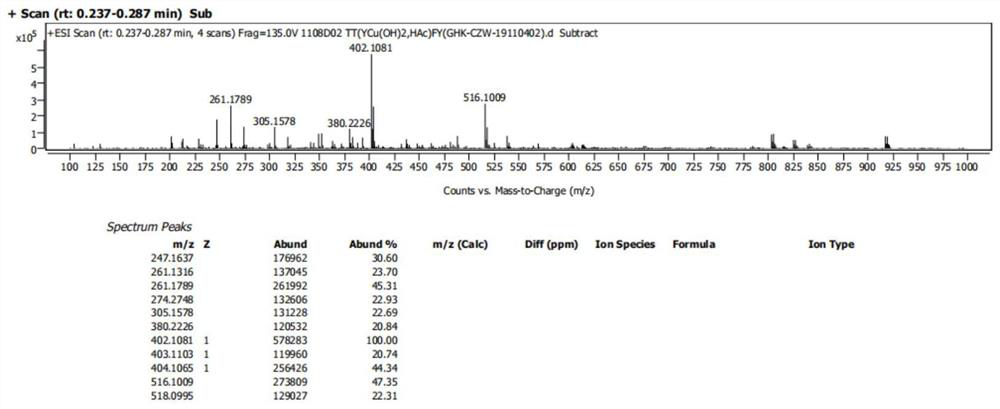

Embodiment 2

[0041] Dissolve 0.54g of copper acetate in 20ml of distilled water, add 1.02g of GHK tripeptide under stirring conditions, stir and react at room temperature (30°C) for 3 hours, filter and concentrate, then add 0.216g of sodium hydroxide, and stir for 30 minutes. Add 70ml of ethanol to precipitate the solid, filter, wash the filter cake with distilled water and then dissolve it in 10ml of distilled water, add 0.13ml of glacial acetic acid, stir and react for 1h, then concentrate and freeze-dry to obtain 0.857g of GHK copper peptide complex with a purity of 98%. The yield is 67%, the acetic acid content is 16.9%, and the copper content is 9.88%.

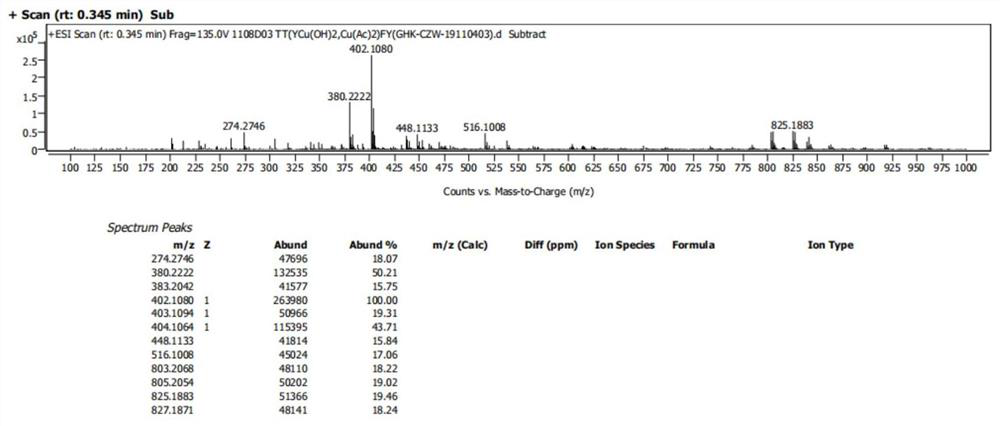

Embodiment 3

[0043] Dissolve 0.25g of copper dimethoxide in 15ml of distilled water, add 0.68g of GHK tripeptide under stirring conditions, stir and react at room temperature (30°C) for 72h, filter and concentrate, then add 0.06ml of glacial acetic acid, and stir for 1h After concentration and freeze-drying, 0.414 g of GHK copper peptide complex with a purity of 99% was obtained, with a yield of 52%, an acetic acid content of 17.7%, and a copper content of 6.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com