High-transparency modified nano calcium masterbatch

A nano-calcium masterbatch technology, applied in the field of nano-calcium masterbatch, can solve the problems of poor transparency, low filling amount and high production cost of blown film products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The invention provides the following technical solutions:

[0029] A highly transparent modified nano-calcium masterbatch, the nano-calcium masterbatch includes the following raw material formula in parts by weight: 70 parts of nano-calcium, 6 parts of low fat-soluble high pressure, 3 parts of high fat-soluble high pressure, 2 parts of low melting point dispersant, Zinc stearate 1 part.

[0030] In a specific embodiment of the present invention, by putting nano-calcium and low-melting-point wax into a high-speed mixer at the same time for stirring, the nano-calcium powder is coated at the initial stage, so that it does not oxidize and burn at high temperature during processing. ;By using wax that melts at low temperature, the nano-calcium powder can be coated, and it is not easy to burn the calcium powder that is not coated with wax after heating up, so that the burned material is not easy to turn yellow; through the corresponding application carrier Resin extrusion gr...

Embodiment 2

[0048] A highly transparent modified nano-calcium masterbatch, the nano-calcium masterbatch includes the following raw material formula in parts by weight: 72 parts of nano-calcium, 7 parts of low-fat-melting high-pressure, 4 parts of high-fat-soluble high-pressure, 3 parts of low-melting wax, hard Zinc fatty acid 1.3 parts.

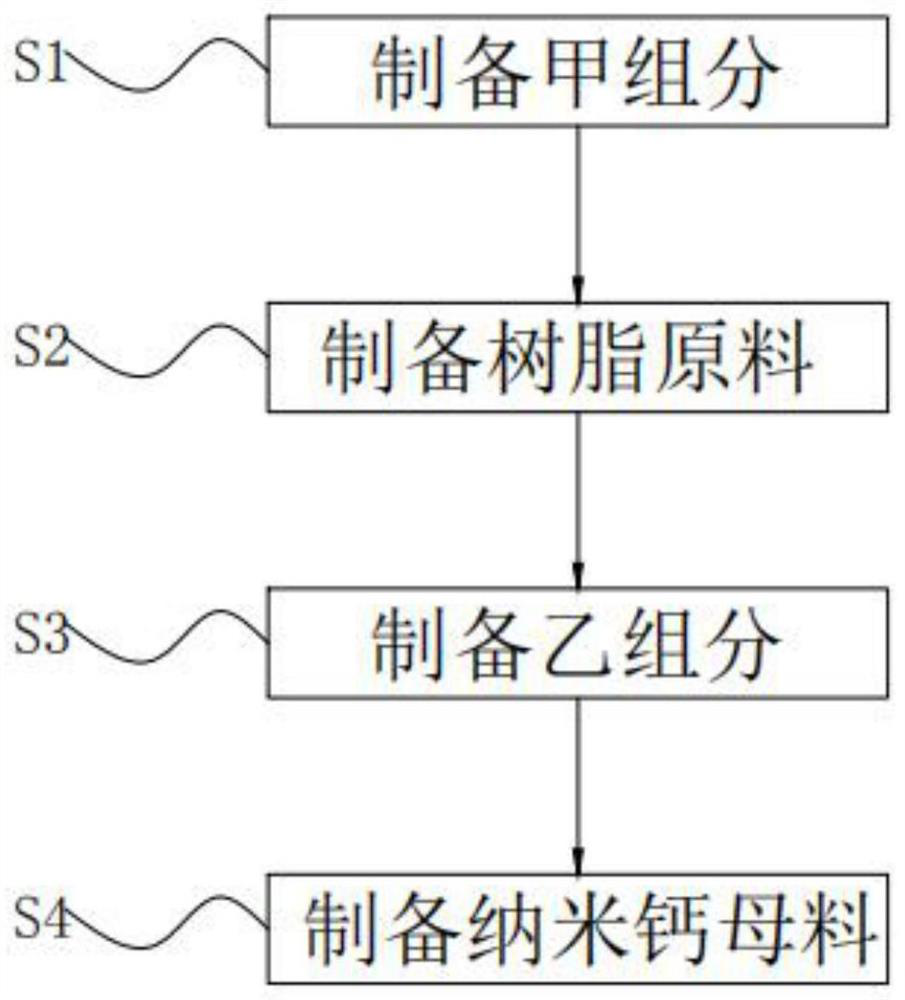

[0049] A method for preparing a highly transparent modified nano-calcium masterbatch, comprising the steps of:

[0050] S1: First select the wax that melts at low temperature, then put the nano-calcium and low-melting point wax into the high-speed mixer at the same time, and stir at a speed of 1200r / min for 5-15min, wait until the nano-calcium and low-melting point wax are mixed and heated to 105 degrees It can be stopped, and at this time, component A is obtained for use;

[0051] S2: After dehydrating the component A at 105 degrees, add low fat-melting high pressure, high fat-melting high pressure, low melting point wax and zinc stearate to the high-s...

Embodiment 3

[0055] A highly transparent modified nano-calcium masterbatch, the nano-calcium masterbatch includes the following raw material formula in parts by weight: 75 parts of nano-calcium, 8 parts of low-fat-soluble high-pressure, 5 parts of high-fat-soluble high-pressure, 4 parts of low-melting point wax, hard Zinc fatty acid 1.5 parts.

[0056] A method for preparing a highly transparent modified nano-calcium masterbatch, comprising the steps of:

[0057] S1: First select the wax that melts at low temperature, then put the nano-calcium and low-melting point wax into the high-speed mixer at the same time, and stir at a speed of 1200r / min for 5-15min, wait until the nano-calcium and low-melting point wax are mixed and heated to 105 degrees It can be stopped, and at this time, component A is obtained for use;

[0058] S2: After dehydrating the component A at 105 degrees, add low fat-melting high pressure, high fat-melting high pressure, low melting point wax and zinc stearate to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com