A multi-layered polypropylene floor

A multi-layer structure, polypropylene technology, used in elastic floors, insulating layers, layered products, etc., can solve the problems of poor dimensional stability of PVC floors, products prone to warping, white pollution, etc., to improve adhesion and adhesion. The effect of knot strength, improved flatness and stability, and improved scratch and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

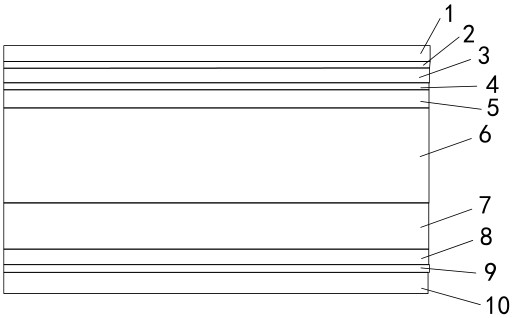

[0062] A multi-layer structure of polypropylene flooring such as figure 1 As shown, UV layer 1, first PP treatment agent layer 2, PP transparent layer 3, second PP treatment agent layer 4, PP printing film layer 5, first substrate layer 6, second substrate layer 7, balance Layer 8, IXPE glue layer 9 and IXPE layer 10 are compounded sequentially, and the compounding method is hot-press bonding; the UV layer is the surface layer; the composition of the first PP treatment agent layer and the second PP treatment agent layer Includes chlorinated polypropylene and organic solvents. The thickness of each layer in the polypropylene floor is shown in the table below:

[0063] Example 1 UV layer PP transparent layer PP printing film first substrate layer second substrate layer balance layer IXPE layer Total thickness Thickness / mm 0.05 0.3 0.15 3 1.2 0.30 1.0 6.0

Embodiment 2

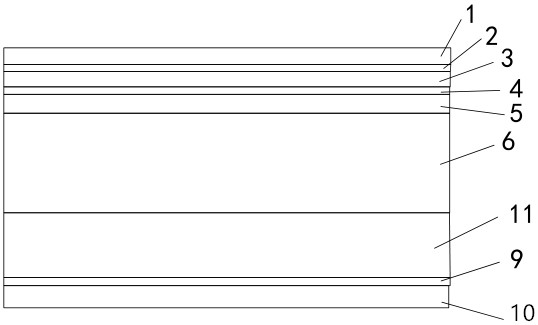

[0065] A multi-layer structure of polypropylene flooring such as figure 2 As shown, UV layer 1, first PP treatment agent layer 2, PP transparent layer 3, second PP treatment agent layer 4, PP printing film layer 5, first substrate layer 6, extruded substrate layer 11, IXPE The glue layer 9 and the IXPE layer 10 are compounded sequentially, and the compounding method is extrusion online lamination; the UV layer is the surface layer, and the composition of the first PP treatment agent layer and the second PP treatment agent layer includes chlorinated Polypropylene and organic solvents. The thickness of each layer in the polypropylene floor is shown in the table below:

[0066] Example 2 UV layer PP transparent layer PP printing film first substrate layer extruded base layer IXPE layer Total thickness Thickness / mm 0.05 0.3 0.15 1.0 3.2 1.0 6.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com