High-reflectivity powder coating

A powder coating, high reflectivity technology, applied in powder coatings, reflective/signal coatings, reflectors, etc., can solve the problems of easy falling off of the coating layer and low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

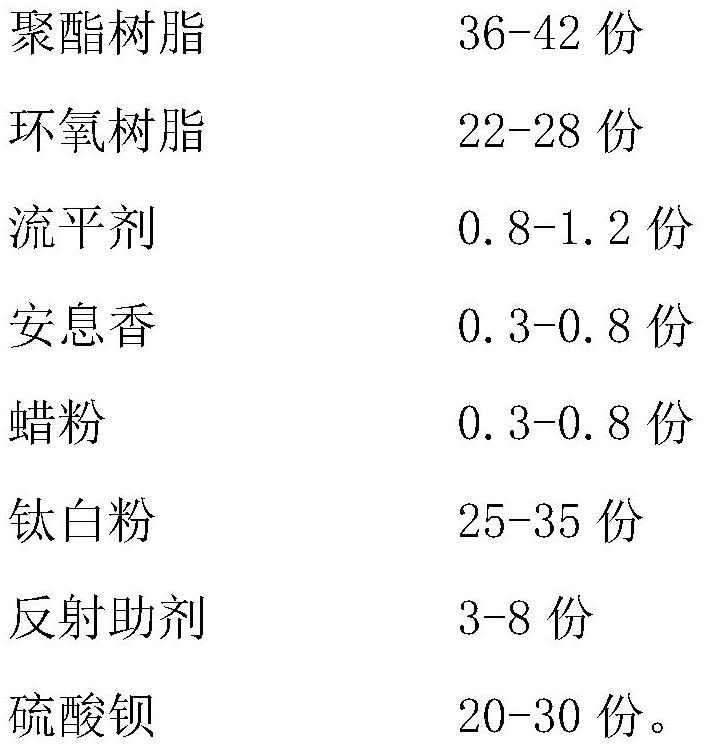

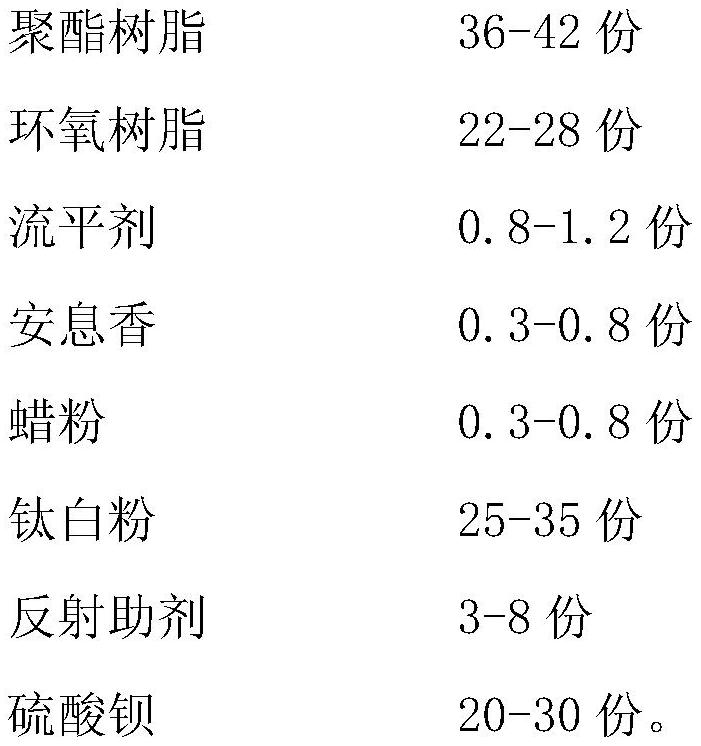

[0028] The application provides a high-reflectivity powder coating. By adding titanium dioxide and reflective additives, the powder coating has a high reflectivity, effectively improves the luminous flux, and achieves energy saving. It specifically includes the following components: polyester Resin, epoxy resin, leveling agent, benzoin, wax powder, titanium dioxide, reflection aid, barium sulfate.

[0029] Wherein, relative to 39 parts by weight of the polyester resin, the epoxy resin is 22-28 parts by weight, and the leveling agent is 0.8-1.2 parts by weight. The viscosity of epoxy resin is 4000-5000mPa.s / 200 degrees, and the acid value is 30-36mPa.s / 200 degrees, while the viscosity of normal resin is 5000-7000mPa.s / 200 degrees, and the acid value is 30-36mPa.s / 200 degrees, the choice of epoxy resin with low acid value and low viscosity ensures the best leveling effect. From the above point of view, further, the epoxy resin is preferably 26 parts by weight, and the leveling ...

Embodiment 1

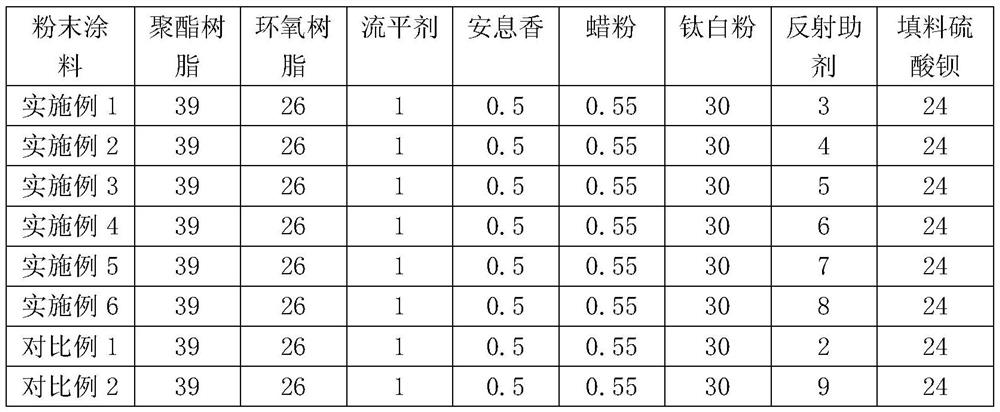

[0037] Take by weight the polyester resin of 39 weight parts, the epoxy resin of 26 weight parts, the leveling agent of 1 weight part, the benzoin of 0.5 weight part, the wax powder of 0.55 weight part, the titanium dioxide of 30 weight parts, 3 Reflection aid in parts by weight, barium sulfate in 24 parts by weight; Feeding: Put the raw materials into the mixer and mix them; Pre-mixing: Mix the raw materials up and down evenly with a Misaic mixer; Extrusion from the machine; tableting: press the extruded bottom material into flakes with a tablet machine; crushing: crush the sheet-shaped bottom material with a crusher; fine crushing: crush the bottom material with a pulverizer; sieve powder packaging: Screen the powder coating with a rotary sieve, and pack the coating into boxes; the pre-mixing step takes high-speed mixing and side shearing and crushing at the same time; the screw rotation speed of the extruder in the melting extrusion mixing step is 50HZ; the temperature durin...

Embodiment 2

[0039] Take by weight the polyester resin of 39 weight parts, the epoxy resin of 26 weight parts, the leveling agent of 1 weight part, the benzoin of 0.5 weight part, the wax powder of 0.55 weight part, the titanium dioxide of 30 weight parts, 4 Reflection aid in parts by weight, barium sulfate in 24 parts by weight; Feeding: Put the raw materials into the mixer and mix them; Pre-mixing: Mix the raw materials up and down evenly with a Misaic mixer; Extrusion from the machine; tableting: press the extruded bottom material into flakes with a tablet machine; crushing: crush the sheet-shaped bottom material with a crusher; fine crushing: crush the bottom material with a pulverizer; sieve powder packaging: Screen the powder coating with a rotary sieve, and pack the coating into boxes; the pre-mixing step takes high-speed mixing and side shearing and crushing at the same time; the screw rotation speed of the extruder in the melting extrusion mixing step is 50HZ; the temperature durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com