Hydrogenation device oil-soluble corrosion inhibitor and preparation method and application thereof

An oil-soluble corrosion inhibitor and hydrogenation device technology, which is applied in the direction of corrosion/fouling treatment equipment, petroleum industry, and hydrocarbon oil treatment, and can solve the problems of oil product quality, poor corrosion inhibition effect, and poor product stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

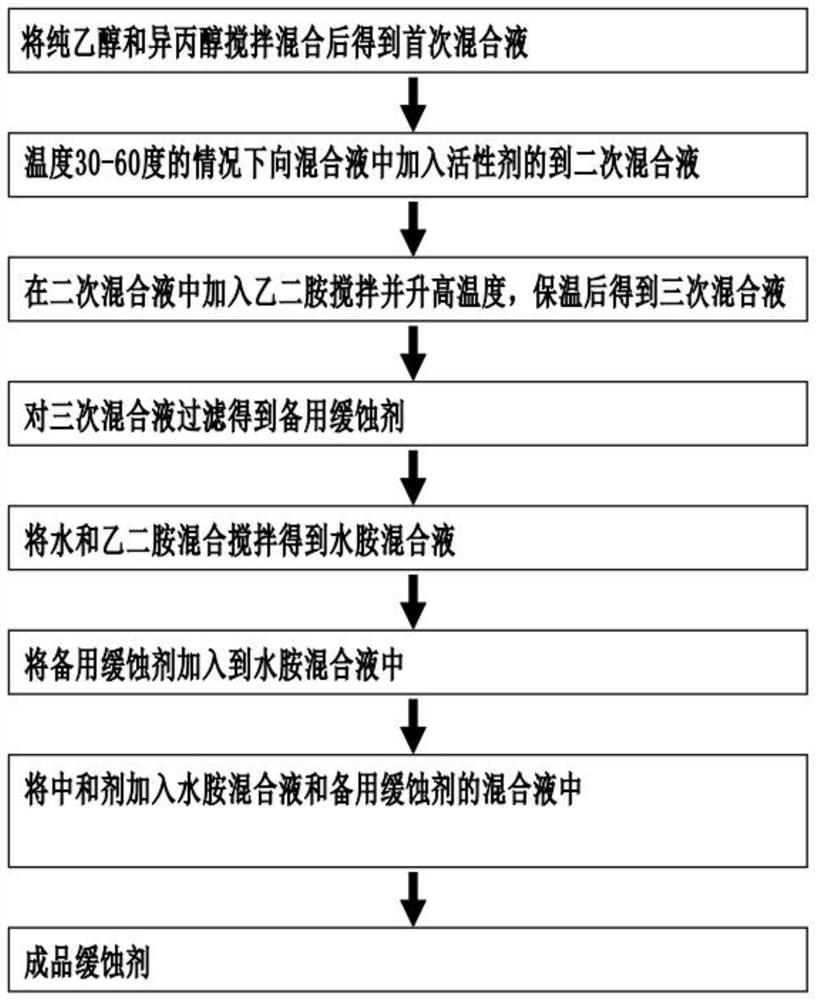

Method used

Image

Examples

preparation example Construction

[0040] A preparation method of an oil-soluble corrosion inhibitor for a hydrogenation unit, comprising the following parts by weight:

[0041] Pure ethanol: 77 parts;

[0042] Isopropanol: 10 parts;

[0043] Active agent: 10 parts;

[0044] Organic corrosion inhibitor: 10 parts;

[0045] Water: 60 parts;

[0046] Ethylenediamine: 31 parts;

[0047] Neutralizer: 1 part.

[0048] Further, the organic corrosion inhibitor is one or a mixture of cis oleylamine ethyl imidazoline, trans oleylamine ethyl imidazoline, and oleylamine ethyl imidazoline.

[0049] Further, the organic corrosion inhibitor is cis oleyl amine ethyl imidazoline, trans oleyl amine ethyl imidazoline and oleyl amine ethyl imidazoline according to the molar ratio of 1-2:1-2:1- 2 composition mixture.

[0050] Further, the neutralizing agent is polyethylene polyamine, and the polyethylene polyamine is one or a mixture of diethylenetriamine, triethylenetetramine and tetraethylenepentamine.

[0051] Further, t...

Embodiment 1

[0064] An oil-soluble corrosion inhibitor for a hydrogenation unit comprises the following components: pure ethanol, isopropanol, active agent, organic corrosion inhibitor, water, ethylenediamine and neutralizing agent.

[0065] A preparation method of an oil-soluble corrosion inhibitor for a hydrogenation unit, comprising the following parts by weight:

[0066] Pure ethanol: 78 parts;

[0067] Isopropanol: 11 parts;

[0068] Active agent: 11 parts;

[0069] Organic corrosion inhibitor: 11 parts;

[0070] Water: 63 parts;

[0071] Ethylenediamine: 36 parts;

[0072] Neutralizer: 3 parts.

[0073] Further, the organic corrosion inhibitor is one or a mixture of cis oleylamine ethyl imidazoline, trans oleylamine ethyl imidazoline, and oleylamine ethyl imidazoline.

[0074] Further, the organic corrosion inhibitor is cis oleyl amine ethyl imidazoline, trans oleyl amine ethyl imidazoline and oleyl amine ethyl imidazoline according to the molar ratio of 1-2:1-2:1- 2 compositi...

Embodiment 2

[0089] An oil-soluble corrosion inhibitor for a hydrogenation unit comprises the following components: pure ethanol, isopropanol, active agent, organic corrosion inhibitor, water, ethylenediamine and neutralizing agent.

[0090] A preparation method of an oil-soluble corrosion inhibitor for a hydrogenation unit, comprising the following parts by weight:

[0091] Pure ethanol: 79 parts;

[0092] Isopropanol: 13 parts;

[0093] Active agent: 13 parts;

[0094] Organic corrosion inhibitor: 13 parts;

[0095] Water: 67 parts;

[0096] Ethylenediamine: 41 parts;

[0097] Neutralizer: 4 parts.

[0098] Further, the organic corrosion inhibitor is one or a mixture of cis oleylamine ethyl imidazoline, trans oleylamine ethyl imidazoline, and oleylamine ethyl imidazoline.

[0099] Further, the organic corrosion inhibitor is cis oleyl amine ethyl imidazoline, trans oleyl amine ethyl imidazoline and oleyl amine ethyl imidazoline according to the molar ratio of 1-2:1-2:1- 2 compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com