Copper-nickel-tin-silver-boron alloy and preparation method thereof

A copper-nickel-tin, silver-boron technology, applied in the field of copper-nickel-tin-silver-boron alloy and its preparation, can solve the problems of high preparation cost, work hardening, high deformation resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Finished product physical property table obtained by the preparation method of the present invention

[0043] Elastic Modulus Poisson's ratio Conductivity Thermal conductivity density Permeability 144Kn / mm 2

Embodiment 1

[0046] Step 1. Mix and heat 14.5% nickel, 7.5% tin, 0.1% boron, 0.1% silver, 0.1% impurities and the balance copper to obtain a melt, then stir evenly, and the heating temperature is 1150 ℃;

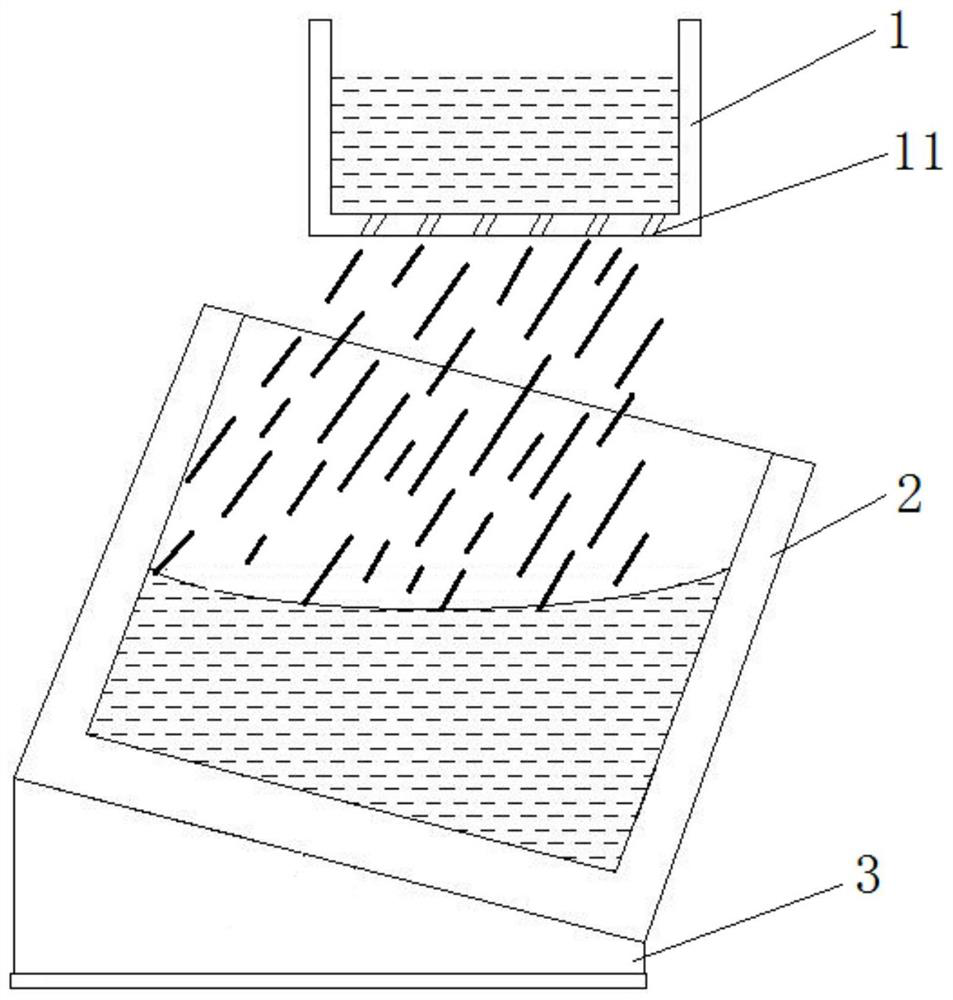

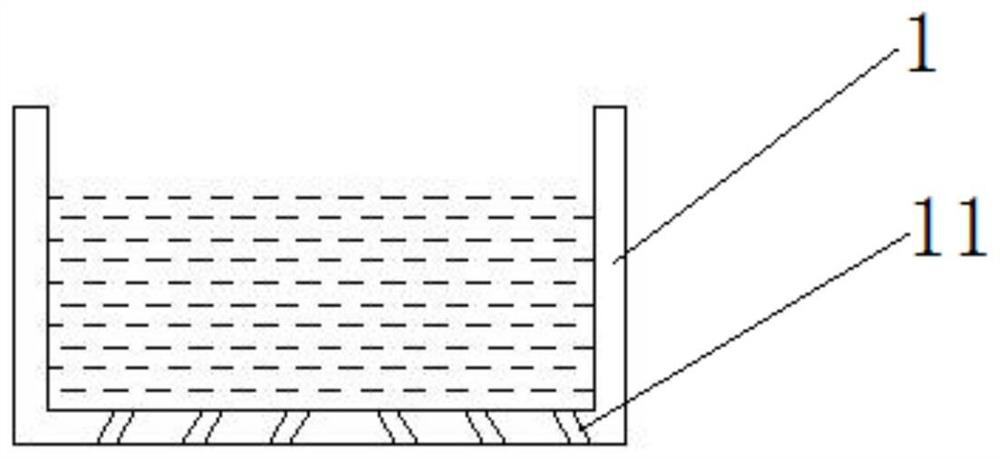

[0047] Step 2. The melt is introduced into the transfer bag 1, and the melt falls into the water-cooled copper mold 2 through the through hole 11 at the bottom of the transfer bag 1. The outer side of the transfer bag 1 is provided with a heat preservation cover with a heating function. The evenly distributed through holes 11 at the bottom of the transfer package 1 are inclined, and the inclined direction is inclined to one side;

[0048] Step 3: The melt is cooled and solidified in the rotating water-cooled copper mold 2. The maximum depth of the melt in the water-cooled copper mold 2 is 60% of the height of the water-cooled copper mold 2. The melt in the water-cooled copper mold 2 is gradually solidified from bottom to top. The water-cooled copper mold 2 is obliquely installed on the ...

Embodiment 2

[0051] Step 1. Mix and heat 15% nickel, 8% tin, 0.5% boron, 0.2% silver, 0.12% impurities and the balance copper to obtain a melt, then stir evenly, and the heating temperature is 1250 ℃;

[0052]Step 2. The melt is introduced into the transfer bag 1, and the melt falls into the water-cooled copper mold 2 through the through hole 11 at the bottom of the transfer bag 1. The outer side of the transfer bag 1 is provided with a heat preservation cover with a heating function. The evenly distributed through holes 11 at the bottom of the transfer bag 1 are inclined, and the direction of inclination is to incline towards the bottom of the transfer bag 1;

[0053] Step 3, the melt is cooled and solidified in the rotating water-cooled copper mold 2, the maximum depth of the melt in the water-cooled copper mold 2 is 55% of the height of the water-cooled copper mold 2, and the melt in the water-cooled copper mold 2 is gradually solidified from bottom to top, The water-cooled copper mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com