Method for rapidly determining sulfur species in solid-phase mineral by using infrared-programmed heating oxidation combination method

A temperature-programmed, rapid measurement technology, applied in the field of analysis and detection, can solve the problems of complex processing, high equipment cost, expensive cost, etc., and achieve the effects of high test accuracy, simple operation and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

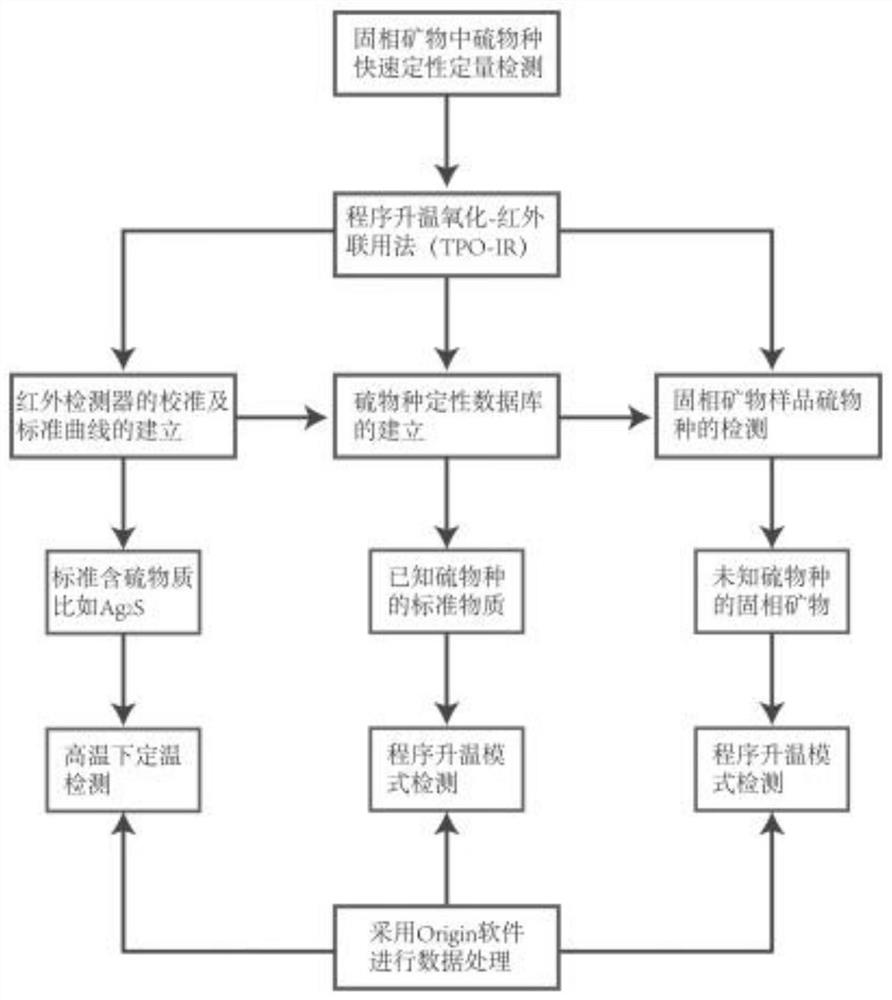

[0058] Such as figure 1 As shown, the method for rapidly determining sulfur species in solid-phase minerals by infrared-programmed temperature oxidation combined method comprises the following steps:

[0059] (1) Crush phosphate rock (produced in Kaiyang, Guizhou), grind, sieve, and dry in an oven at 80°C to obtain 200-mesh phosphate rock powder. Weigh 1573.8 mg of 200-mesh phosphate rock with a precision balance (accuracy greater than 1 / 10,000). Put the phosphate rock powder into the ceramic boat after roasting at 1200°C for 8 hours;

[0060] (2) Put the ceramic boat containing phosphate rock powder into the constant temperature zone of the tube furnace, and set the temperature rise program from 20°C to 1050°C at a rate of 10°C / min, turn on the infrared carbon and sulfur analyzer, and turn on the computer control software, input the weighed sample mass (1573.8mg), sampling time (6180s) and other parameters, open the carrier gas O 2 (purity>99.5%), set the flow rate to 1.8L / ...

Embodiment 2

[0062] The method for quickly determining sulfur species in solid-phase minerals by infrared-programmed temperature oxidation combined method comprises the following steps:

[0063] (1) Crush phosphate rock (produced in Weng'an, Guizhou), grind, sieve, and dry in an oven at 80°C to obtain 200-mesh phosphate rock powder, and weigh 1165.5 mg of 200-mesh phosphate rock with a precision balance (accuracy greater than 1 / 10,000). Put the phosphate rock powder into the ceramic boat after roasting at 1200°C for 8 hours;

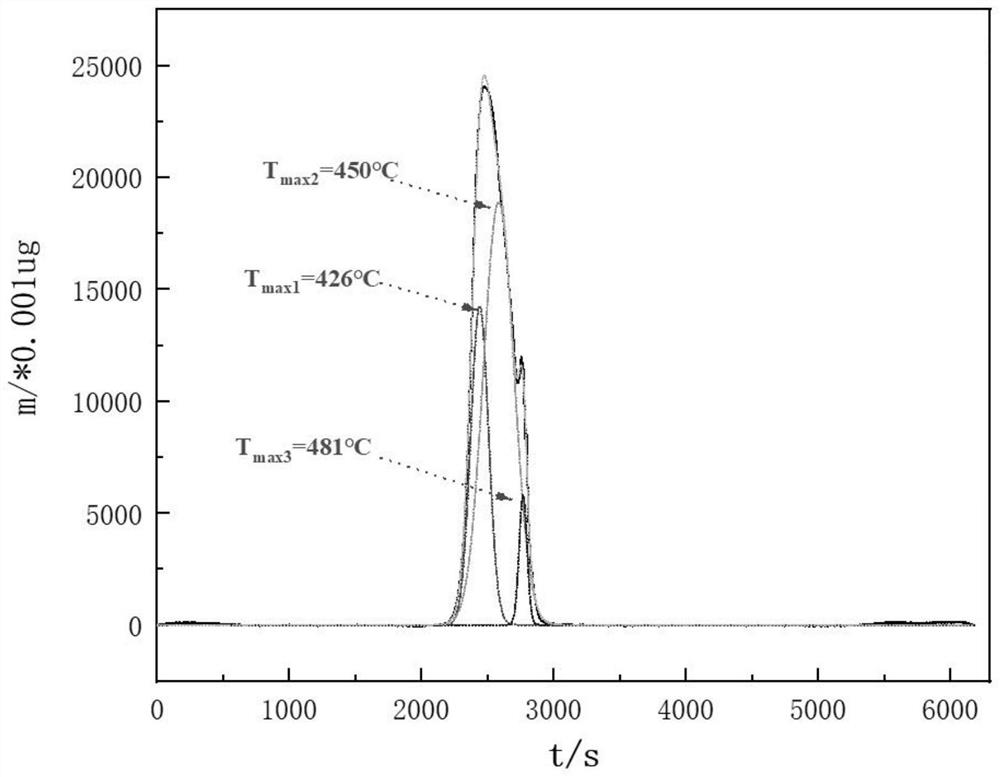

[0064] (2) Put the sample into the constant temperature zone of the tube furnace, and set the temperature rise program from 20°C to 1050°C at a rate of 10°C / min, turn on the infrared carbon and sulfur analyzer, turn on the computer control software, and input the weighing The sample quality (1165.5mg), sampling time (6180s) and other parameters, open the carrier gas O 2 (purity>99.5%), set the flow rate to 1.8L / min; start sampling after the baseline of the infrared ...

Embodiment 3

[0066] The method for quickly determining sulfur species in solid-phase minerals by infrared-programmed temperature oxidation combined method comprises the following steps:

[0067] (1) Pulverize gas coal (Chongqing Yongchuan Coal Mine), grind, sieve, and dry in an oven at 80°C to obtain 80-mesh phosphate rock powder, and weigh 62.34 mg of 80-mesh phosphate rock powder with a precision balance (accuracy greater than 1 / 10,000). Put the phosphate rock powder into the ceramic boat after roasting at 1200°C for 8 hours,

[0068] (2) Put the sample into the constant temperature zone of the tube furnace, and set the temperature rise program from 20°C to 1050°C at a rate of 10°C / min, turn on the infrared carbon and sulfur analyzer, turn on the computer control software, and input the weighing The sample quality (62.34mg), sampling time (6180s) and other parameters, open the carrier gas O 2 (purity>99.5%), the flow rate is set to 1.8L / min; after the infrared carbon and sulfur analyzer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com