Rapid turn-off RC-IGBT device with back double-MOS structure

A MOS structure and fast technology, applied in the semiconductor field, can solve the problems of long tail current, large voltage drop, and unsatisfactory breakdown voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

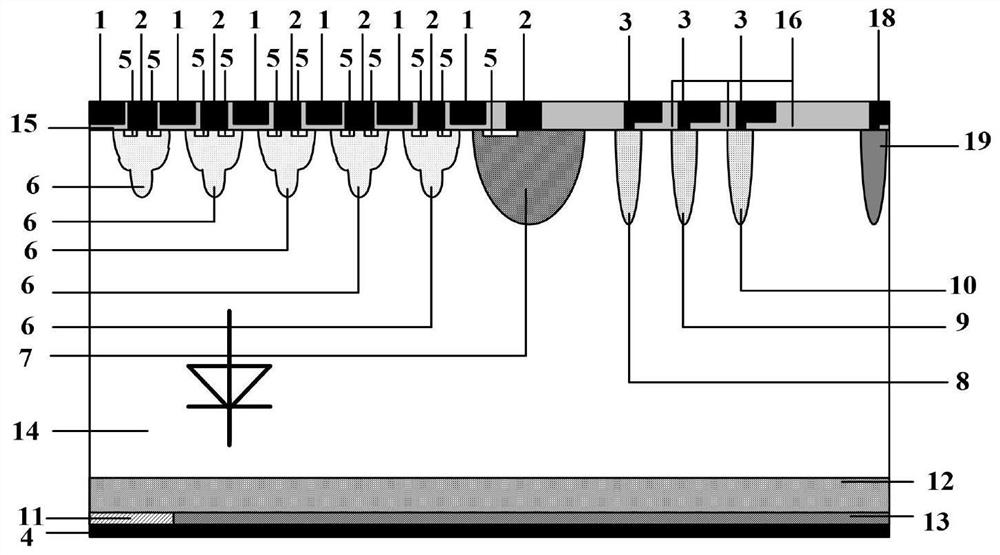

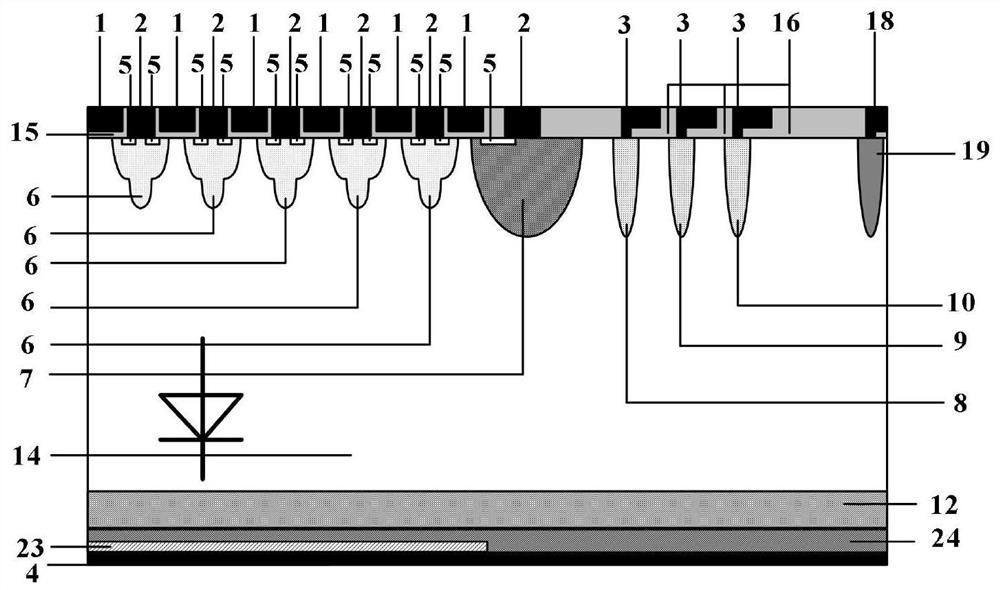

[0047] Such as Figure 6 As shown, a preferred embodiment of the present invention has a fast turn-off RC-IGBT device with a double MOS structure on the back, including a gate contact region 1, an emitter contact region 2, a metal field plate 3, a collector contact region 4, an emitter Pole 5, P-type well in cell region 6, P-type well in transition region 7, first field-limiting ring 8, second field-limiting ring 9, third field-limiting ring 10, N-type collector 11, N-type buffer layer 12 , P-type collector 13, N-type drift region 14, gate oxide layer 15, field oxide layer 16, collector oxide layer 17, field stop ring contact area 18, field stop ring 19, collector P-base 20;

[0048] The lower surface of the P-type collector 13 in the left, middle and right parts completely covers the upper surface of the collector contact region 4 . The left and right parts of the P-type collector 13 are doped silicon with a thickness of 2 μm, the middle concave part is doped silicon with a ...

Embodiment 2

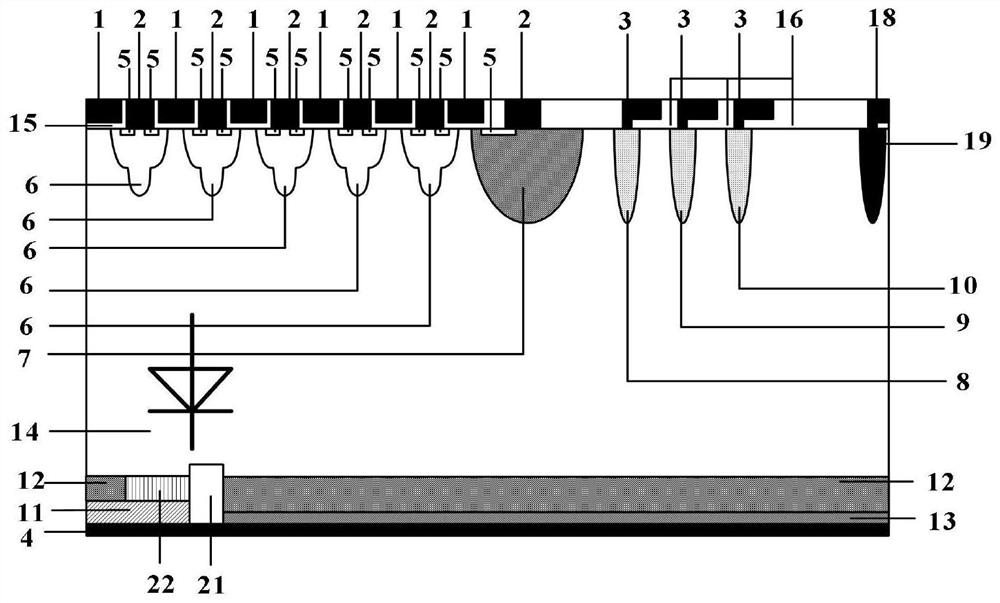

[0068] Such as Figure 7 As shown, the embodiment of the present invention preferably has a fast turn-off RC-IGBT device with a double MOS structure on the back. On the structure of Example 1, the silicon dioxide layer 17 of the MOS structure on the back is deep into the N-type buffer layer 12. At the same time, the collector metal contact region 4 and the P-type collector 13 part in the middle also penetrate into the N-type buffer layer 12, and the three keep the upper surface flush, and are located at the lower 0.5 μm of the N-type buffer layer 12. The N-type The surface of the buffer layer 12 is no longer concave, and the P-type collector in the middle part is 0.5 μm higher than the P-type collectors on both sides.

[0069] With the help of MEDICI simulation software, it is available for the provided figure 1 As shown in the traditional RC-IGBT, as Figure 5 The shown double anode type DARC-IGBT and the example proposed by the present invention are as Figure 6 The new ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com