Daily ration for preventing ruminant foam type rumen flatulence and preparation method thereof

A ruminant, foam-type technology, applied in animal feed, animal feed, additional food elements, etc., to achieve the effect of facilitating digestion, reducing time, and inhibiting the loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Second, the present invention provides a preparation method for preventing ruminant foam type rumen flatulence ration, it is characterized in that, comprises the following steps:

[0024] S1: Obtain the first component after ultrafine grinding and high-pressure cooking of corn, wheat bran, cake feed, and plant dregs;

[0025] S2 Mixing the first component with oat grass, ramie, inorganic additives, and premix to obtain the second component.

[0026] In the present invention, polysaccharase is added to S2.

[0027] In the present invention, in the S1, the pulverization particle size of the superfine pulverization is 100 mesh to 200 mesh, or 100 mesh to 150 mesh, or 150 mesh to 200 mesh.

[0028] In the present invention, in the S1, the pressure of high-pressure cooking is 80MPa-150MPa, or 80MPa-120MPa, or 80MPa-100MPa, or 100MPa-150MPa, or 100MPa-120MPa, and the time is 10min-20min.

Embodiment 1-6

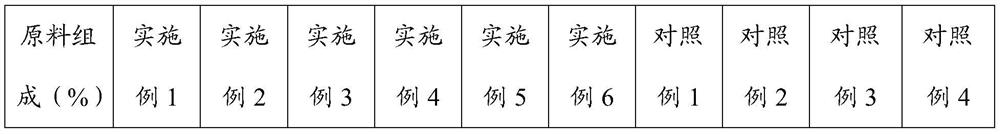

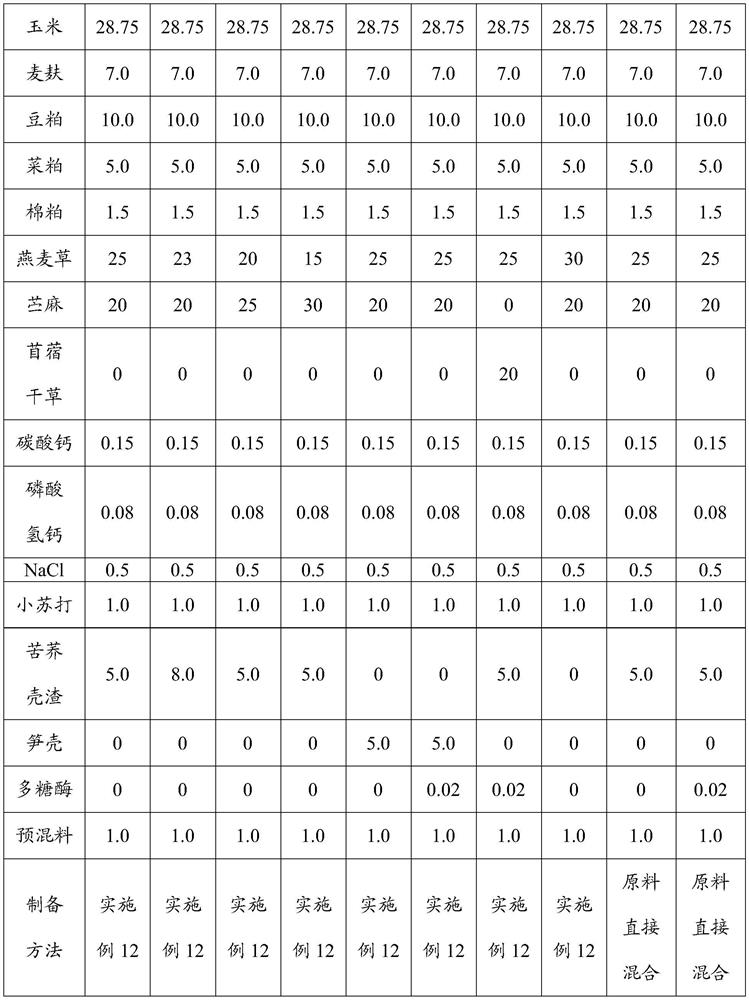

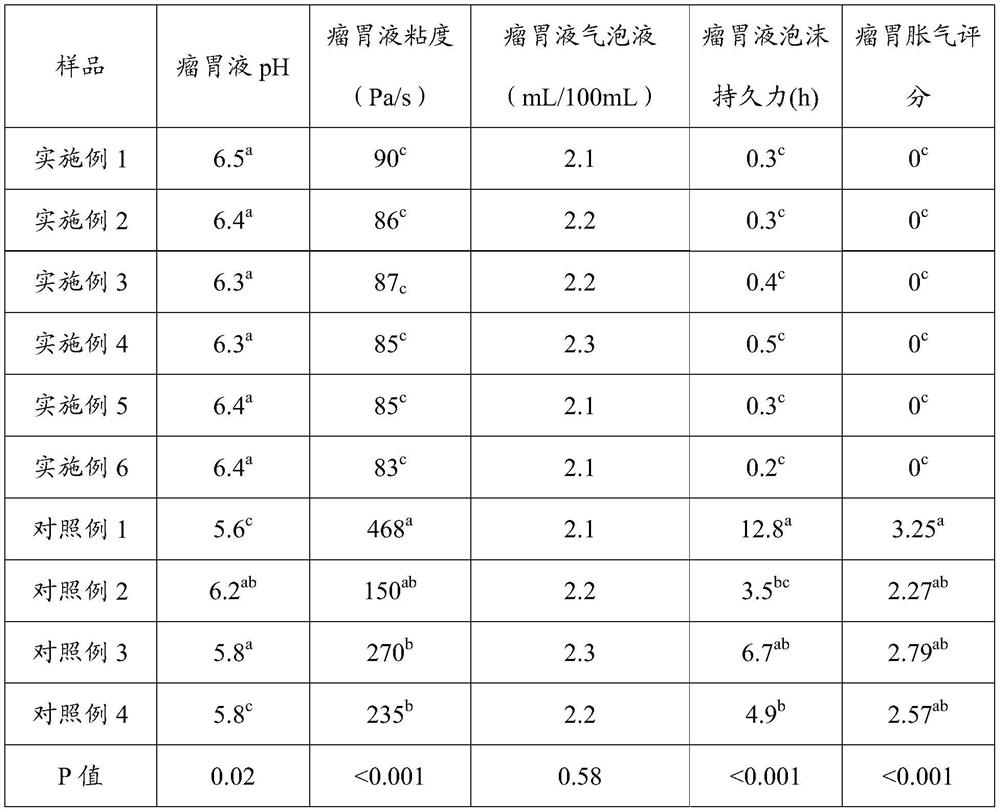

[0030] A ration for preventing foamy rumen flatulence of ruminants, comprising corn, wheat bran, soybean meal, rapeseed meal, cotton meal, oat grass, ramie, calcium carbonate, calcium hydrogen phosphate, sodium chloride, baking soda, tartary buckwheat husk residue or Shoot shells and premixes, with or without polysaccharidase. The weight percentages of the above-mentioned components are shown in Table 1.

Embodiment 7

[0032]A ration for preventing foamy rumen flatulence of ruminants, each component is calculated by weight percentage, including 25% of corn, 8% of wheat bran, 8% of soybean meal, 5% of rapeseed meal, 2% of cotton meal, 15% of oat grass, ramie 30%, calcium carbonate 0.2%, calcium hydrogen phosphate 0.1%, NaCl 0.5%, baking soda 1.0%, premix 2%, tartary buckwheat shell residue 8% and 0.02% polysaccharase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com