Metal ion/zirconium phosphate aerogel, preparation method thereof and composite phase change energy storage material

A metal ion, zirconium phosphate technology, applied in aerogel preparation, heat exchange materials, chemical instruments and methods, etc., can solve the problems of insufficient mechanical strength, poor compatibility and collapse of composite phase change materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

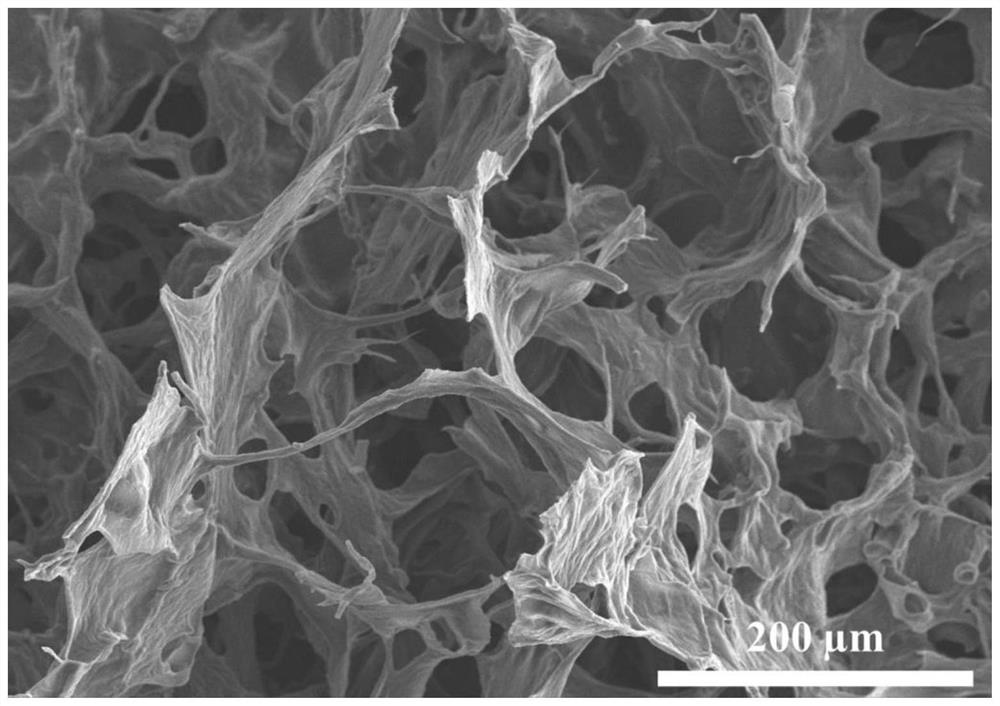

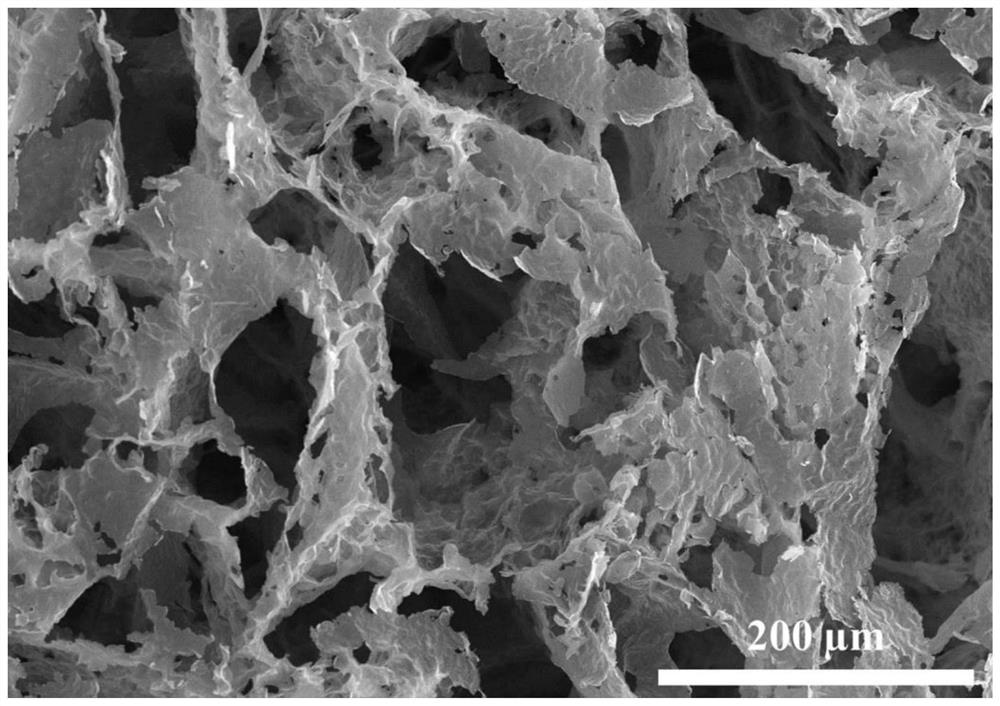

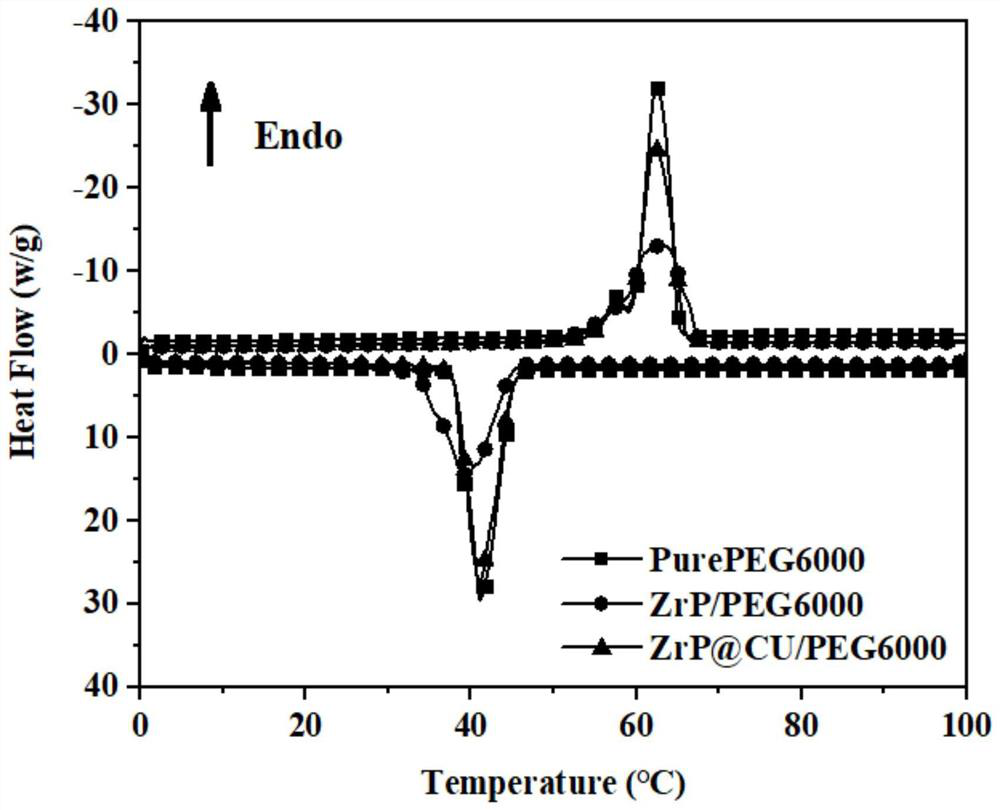

[0049] 1. Add 1.0g of unstripped zirconium phosphate powder (thickness 100-200nm, sheet diameter 1-4μm) into 500mL Tris solution with a concentration of 1.5mg / mL, shake vigorously to completely dissolve zirconium phosphate;

[0050] 2. The prepared zirconium phosphate solution was subjected to 150w 45kHz ultrasonic treatment for 2 hours, during which time it was taken out and shaken for 5 minutes every 0.5 hours, and after the ultrasonic treatment was completed, it was allowed to stand at room temperature for 12 hours;

[0051] 3. Pour the solution after standing still into a container for freeze-drying treatment for 48 hours at a freezing temperature of -40°C to obtain zirconium phosphate airgel;

[0052] 4. Immerse the zirconium phosphate airgel in 0.1 mg / mL copper sulfate solution, and let it stand at room temperature for 24 hours;

[0053] 5. Take out the zirconium phosphate airgel treated with metal ions, and carry out vacuum freeze-drying treatment for 48 hours at a free...

Embodiment 2

[0060] 1. Add 1.0g of unexfoliated zirconium phosphate powder (100-200nm in thickness, 1-4μm in diameter) into 500ml of Tris solution with a concentration of 1.5mg / mL, and shake vigorously to completely dissolve the zirconium phosphate;

[0061] 2. The prepared zirconium phosphate solution was subjected to 150w 45kHz ultrasonic treatment for 2 hours, during which time it was taken out and shaken for 5 minutes every 0.5 hours, and after the ultrasonic treatment was completed, it was allowed to stand at room temperature for 12 hours;

[0062] 3. Pour the solution after standing still into a container for freeze-drying treatment for 48 hours at a freezing temperature of -40°C to obtain zirconium phosphate airgel;

[0063] 4. Immerse the zirconium phosphate airgel in 0.1 mg / mL zinc sulfate solution, and let it stand at room temperature for 24 hours;

[0064] 5. Take out the zirconium phosphate airgel after the metal ion treatment, and carry out vacuum freeze-drying treatment for 4...

Embodiment 3

[0068] 1. Add 1.0g of unexfoliated zirconium phosphate powder (thickness 100-200nm, sheet diameter 1-4μm) into 500ml Tris solution with a concentration of 1.5mg / ml, shake vigorously to completely dissolve zirconium phosphate;

[0069] 2. The prepared zirconium phosphate solution was subjected to 150w 45kHz ultrasonic treatment for 2 hours, during which time it was taken out and shaken for 5 minutes every 0.5 hours, and after the ultrasonic treatment was completed, it was allowed to stand at room temperature for 12 hours;

[0070] 3. Pour the solution after standing still into a container for freeze-drying treatment for 48 hours at a freezing temperature of -40°C to obtain zirconium phosphate airgel;

[0071] 4. Immerse the zirconium phosphate airgel in 0.1 mg / mL nickel sulfate solution, and let it stand at room temperature for 24 hours;

[0072] 5. Take out the zirconium phosphate airgel treated with metal ions, and carry out vacuum freeze-drying treatment for 48 hours at a fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Peak heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com