Automatic circulating cooling sand-building treatment system for iron and steel castings

An automatic circulation and sand treatment technology, applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., can solve the problem of low labor intensity for workers, hot casting sand and cooling liquid and air cooling medium Insufficient contact, poor cooling effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

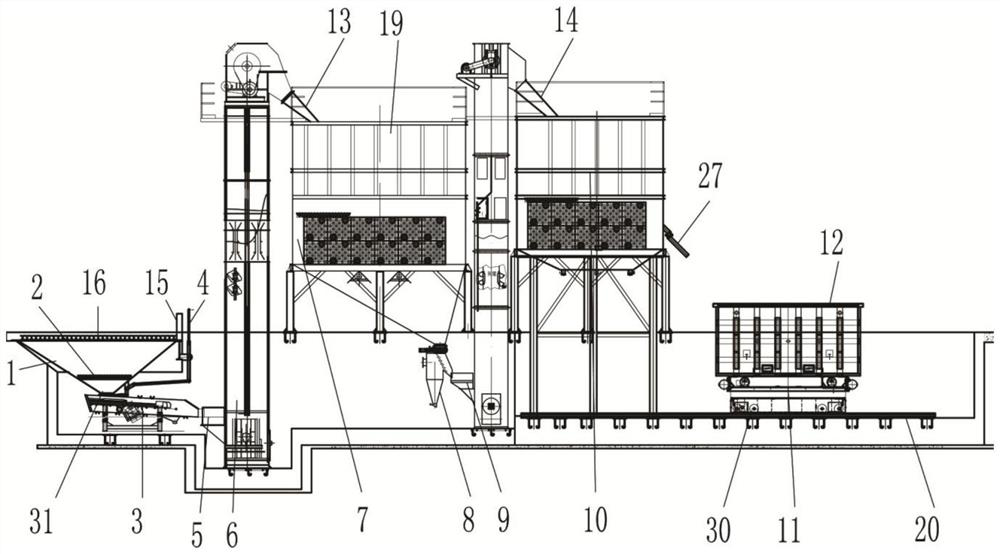

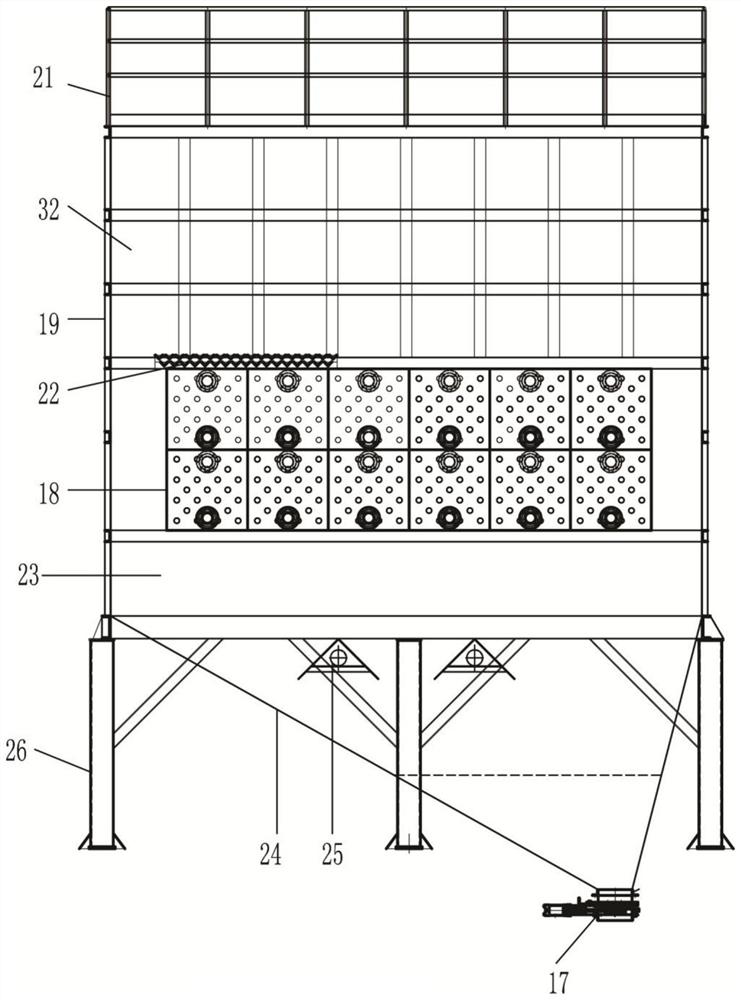

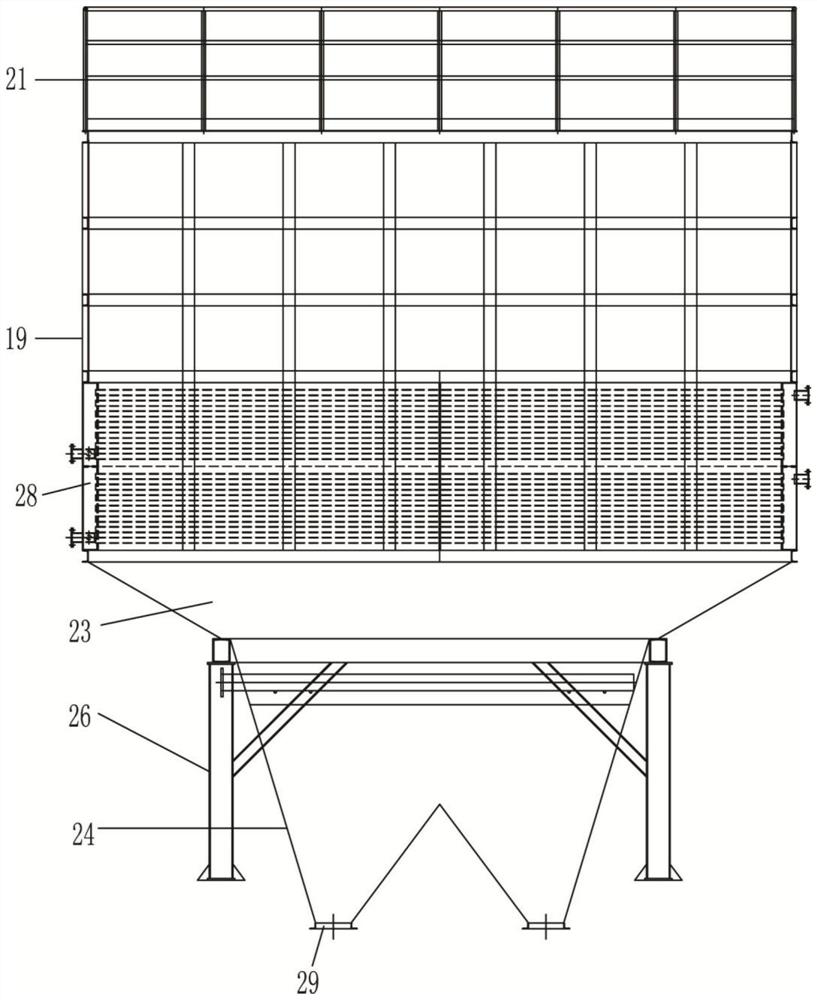

[0040]The invention discloses an automatic circulating cooling sand processing system for iron and steel castings. This embodiment uses a set of casting sand lifting processing unit and casting sand cooling unit to form an integral cooling device. The two above cooling devices are connected together. A cooling system for the casting sand is formed in series to cool the hot casting sand, that is, the hot casting sand is cooled by the casting sand cooling device in the sand storage box device 7 of the first sand storage device, that is, the casting sand cooling unit, and then cooled from the lower sand storage The sand outlet (29) at the outlet end of the bucket (24) is sorted by the air separator 8 and then transported to the casting sand cooling unit of the second sand storage box device 10 by the belt type sand conveyor 9 after being cooled and then enters In the casting sand box 12, the casting is sanded. The following is a detailed description of the specific implementation...

Embodiment 2

[0047] In this embodiment, a set of casting sand lifting processing unit and casting sand cooling unit are used to form an integrated cooling device, that is, the hot casting sand first passes through the first sand storage device, that is, the sand storage box device 7 of the casting sand cooling unit. After the casting sand cooling device is cooled, it is sorted by the air separator 8 and then transported by the belt sand conveyor 9 or directly enters the casting sand box 12 through the chute 27 to process the castings. The following is a detailed description of the specific implementation process. The foundry sand used in the present invention is commonly used molding sand during the existing lost foam casting.

[0048] The raw material used in this embodiment is all scrap steel smelting, and the furnace charge composition is A3 steel plate and silicon steel sheet each accounting for 50%, plus an appropriate amount of recarburizer, ferrosilicon, etc.; the smelting temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com