Preparation method and application of biomass hard carbon for sodium ion battery negative electrode material

A sodium-ion battery and negative electrode material technology, applied in the preparation/purification of carbon, battery electrodes, electrolyte storage battery manufacturing, etc., can solve the problem of low specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Example of the present invention provides a kind of preparation method of biomass hard carbon for sodium ion battery negative electrode material, comprises the steps:

[0034] S01. Provide the raw material longan shell, soak in hot water and acidic solution, and dry to obtain the precursor;

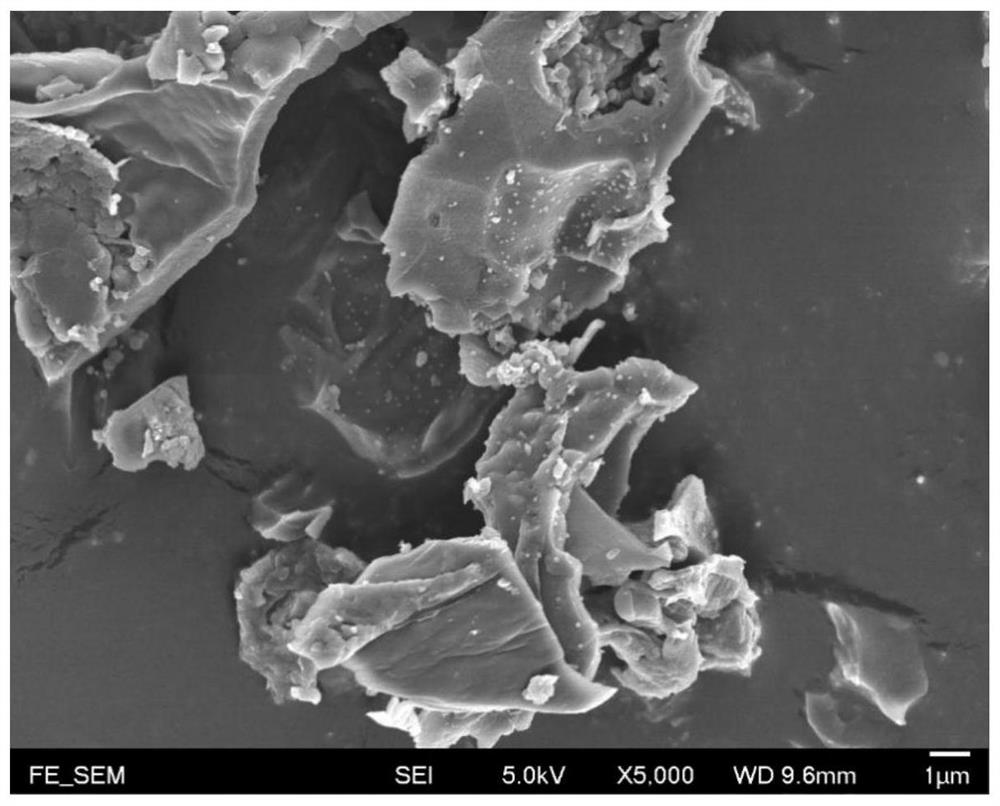

[0035] S02. Introduce a protective gas, preheat the precursor, and grind it after cooling to obtain an intermediate product;

[0036] S03. Carry out carbonization treatment on the intermediate product, and obtain biomass hard carbon after cooling.

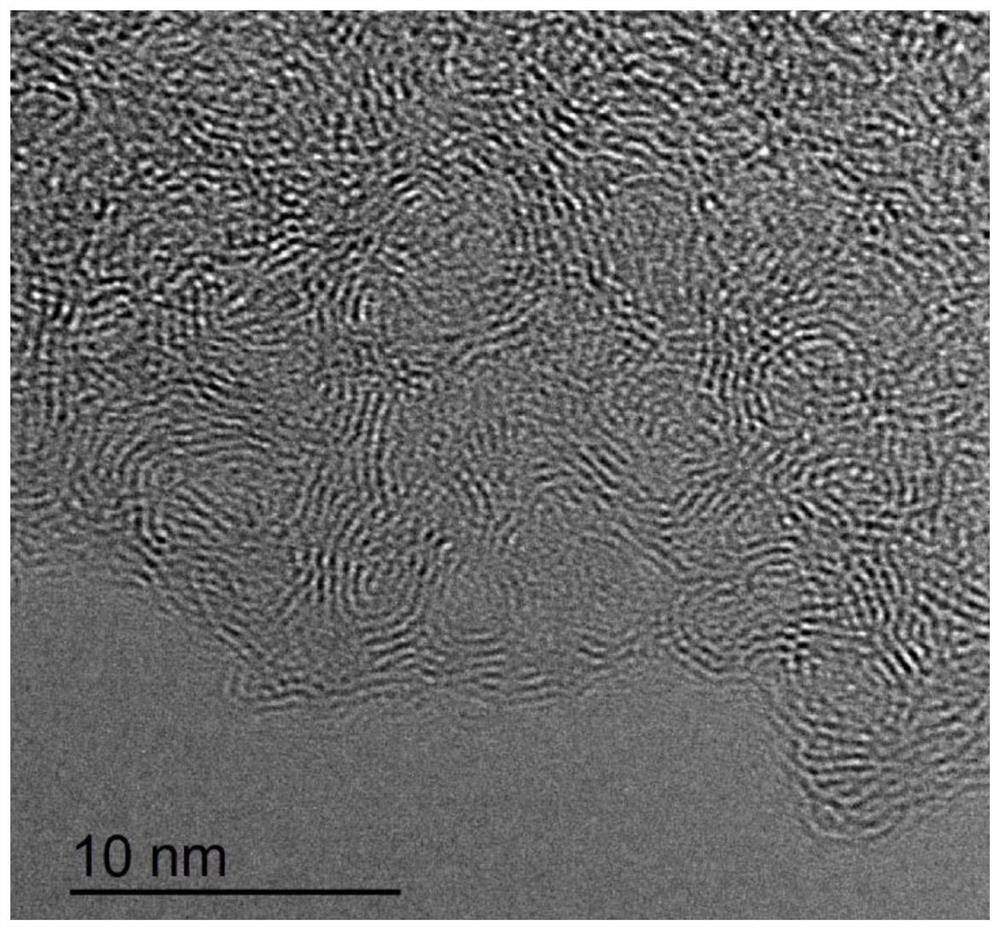

[0037] Specifically, longan shells are provided as raw materials, and longan shells are selected as raw materials, mainly because the composition of longan shells is different from other biomass. The main components of longan shells are 45.5% cellulose, 2.1% hemicellulose and 18.7% lignin. The hard carbon obtained from "longan shell" is used as the negative electrode material for sodium ions. Due to its special material structure, the ...

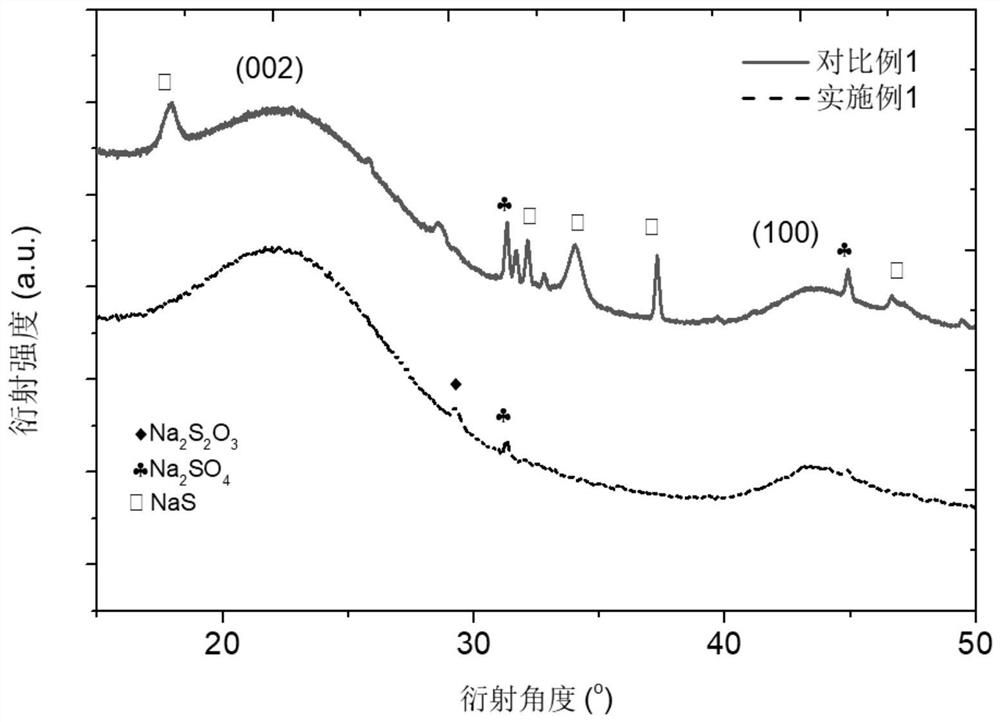

Embodiment 1

[0071] A kind of preparation method of biomass hard carbon for sodium ion battery negative electrode material

[0072] Wash the longan skin three times with clear water, and immerse it in 100° C. deionized water for 1 hour. After taking it out, soak the longan skin in 1mol / L hydrochloric acid for 24 hours. Soak in deionized water several times until neutral. The soaked longan skin is dried at 120° C. for 12 hours and then pulverized to obtain a precursor. Take 4.0g of the precursor and carry out low-temperature pretreatment in a tube furnace with argon (50sccm), raise the temperature to 450°C at a heating rate of 5°C / min, keep it warm for 1 hour, and grind it evenly after natural cooling to obtain an intermediate product. Weigh 1.0g of the intermediate product, lay it flat in a corundum crucible, put it into an argon-protected tube furnace for calcination, first raise the temperature to 450°C, keep it warm for 0.5 hours, then raise the temperature to 1350°C, keep it warm for...

Embodiment 2

[0076] A kind of preparation method of biomass hard carbon for sodium ion battery negative electrode material

[0077] Wash the longan skin three times with clear water, and immerse it in 100° C. deionized water for 1 hour. After taking it out, soak the longan skin in 1mol / L hydrochloric acid for 24 hours. Soak in deionized water several times until neutral. The soaked longan skin is dried at 120° C. for 12 hours and then pulverized to obtain a precursor. Take 4.0g of the precursor and carry out low-temperature pretreatment in a tube furnace with argon (50sccm), raise the temperature to 450°C at a heating rate of 5°C / min, keep it warm for 1 hour, and grind it evenly after natural cooling to obtain an intermediate product. Weigh 1.0g of the intermediate product, lay it flat in a corundum crucible, put it into an argon-protected tube furnace for calcination, first raise the temperature to 450°C, keep it warm for 0.5 hours, then raise the temperature to 1200°C, keep it warm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com