Preparation method of hierarchical pore ZSM-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, nanotechnology for materials and surface science, etc., to achieve the effect of improving utilization rate, reducing production cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

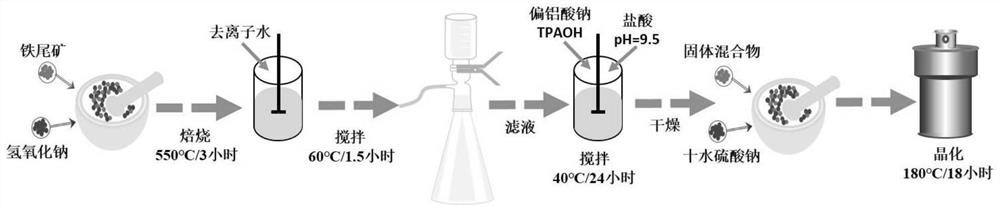

Method used

Image

Examples

Embodiment 1

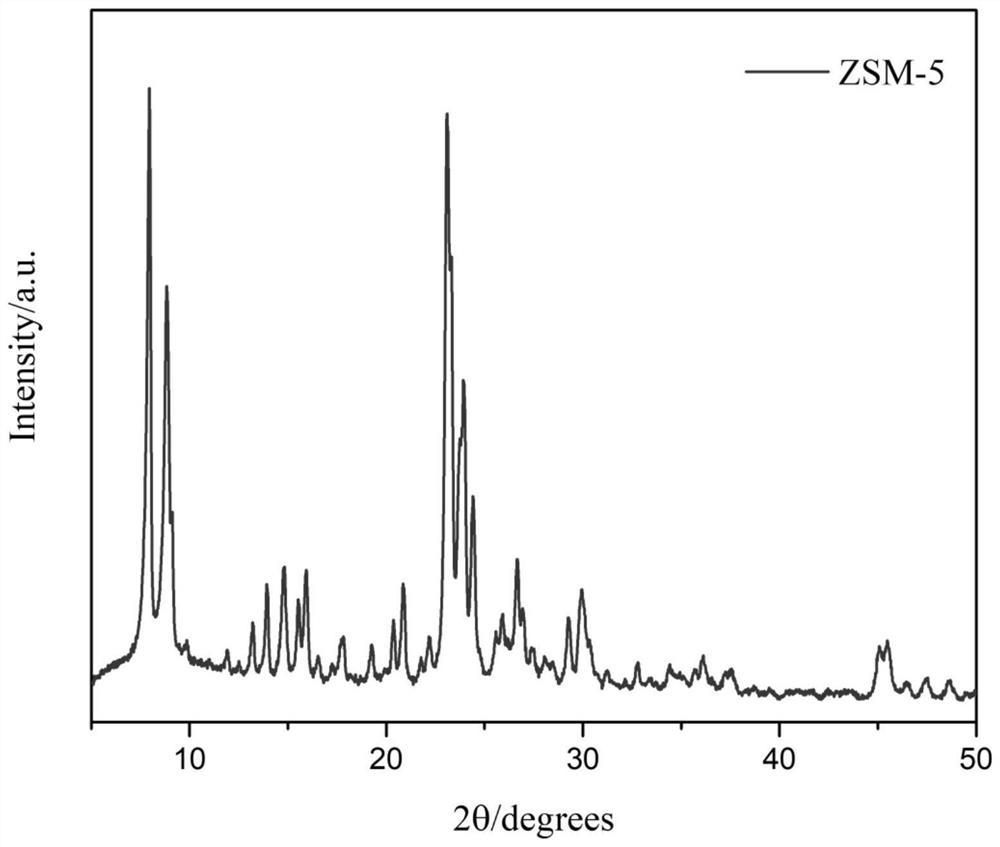

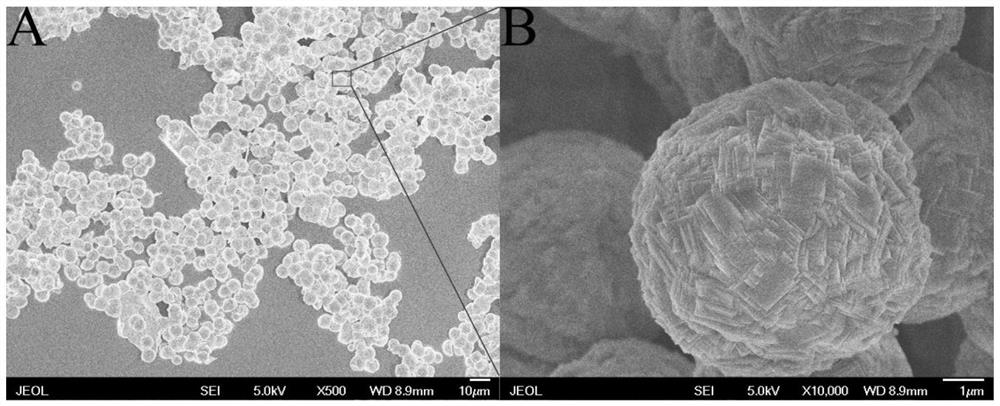

[0033] Using high-silicon tailings in a certain place as raw material (SiO 2Grade is 68.8%), after weighing 5.0g tailings, 4.6g sodium hydroxide mixes uniformly respectively, put into muffle furnace 500 ℃ of roasting 3 hours; After the mixture is cooled, add a certain amount of distilled water 60 ℃ magnetic stirring for 1.5 hours, And carry out suction filtration on it, add a certain amount of sodium metaaluminate and TPAOH solution to the obtained solution, adjust the pH value of the solution to 9.5 with 2mol / L hydrochloric acid, continue to stir at 40°C for 24 hours, then stop stirring and place the solution at 60°C Under aging for 8 hours. Finally, open the lid of the container containing the mixed solution and dry the resulting solution. Add 1.85 g of sodium sulfate decahydrate to the dried solid mixture, mix and grind for 5 minutes, put the mixture into a sealed stainless steel reaction kettle and raise the temperature to 180° C. for 18 hours for crystallization. After ...

Embodiment 2

[0035] Using high-silicon tailings in a certain place as raw material (SiO 2 Grade is 68.8%), after weighing 5.0g tailings, 4.6g sodium hydroxide mixes uniformly respectively, put into muffle furnace 500 ℃ of roasting 3 hours; After the mixture is cooled, add a certain amount of distilled water 60 ℃ magnetic stirring for 1.5 hours, And carry out suction filtration on it, add a certain amount of sodium metaaluminate and TPAOH solution to the obtained solution, adjust the pH value of the solution to 9.5 with 2mol / L hydrochloric acid, continue to stir at 40°C for 24 hours, then stop stirring and place the solution at 60°C Under aging for 8 hours. Finally, open the lid of the container containing the mixed solution and dry the resulting solution. Add 1.85g of sodium sulfate decahydrate to the dried solid mixture, mix and grind for 5 minutes, put the mixture into a sealed stainless steel reaction kettle and raise the temperature to 160°C for 24 hours for crystallization. After th...

Embodiment 3

[0037] Using high-silicon tailings in a certain place as raw material (SiO 2 Grade is 68.8%), after weighing 5.0g tailings, 4.6g sodium hydroxide mixes uniformly respectively, put into muffle furnace 500 ℃ of roasting 3 hours; After the mixture is cooled, add a certain amount of distilled water 60 ℃ magnetic stirring for 1.5 hours, And carry out suction filtration on it, add a certain amount of sodium metaaluminate and TPAOH solution to the obtained solution, adjust the pH value of the solution to 9.5 with 2mol / L hydrochloric acid, continue to stir at 40°C for 24 hours, then stop stirring and place the solution at 60°C Under aging for 8 hours. Finally, open the lid of the container containing the mixed solution and dry the resulting solution. Add 1.85 g of sodium sulfate decahydrate to the dried solid mixture, mix and grind for 5 minutes, put the mixture into a sealed stainless steel reaction kettle and raise the temperature to 140° C. to stand at a constant temperature for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com